Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - ForGe Control (PanelView 550) User Manual

Page 97

Rockwell Automation Publication 7000-UM151E-EN-P - January 2013

97

Component Definition and Maintenance Chapter 3

If vertical, the impeller and bushing may fall when loosening cap screws. Physical

injury or component damage may result.

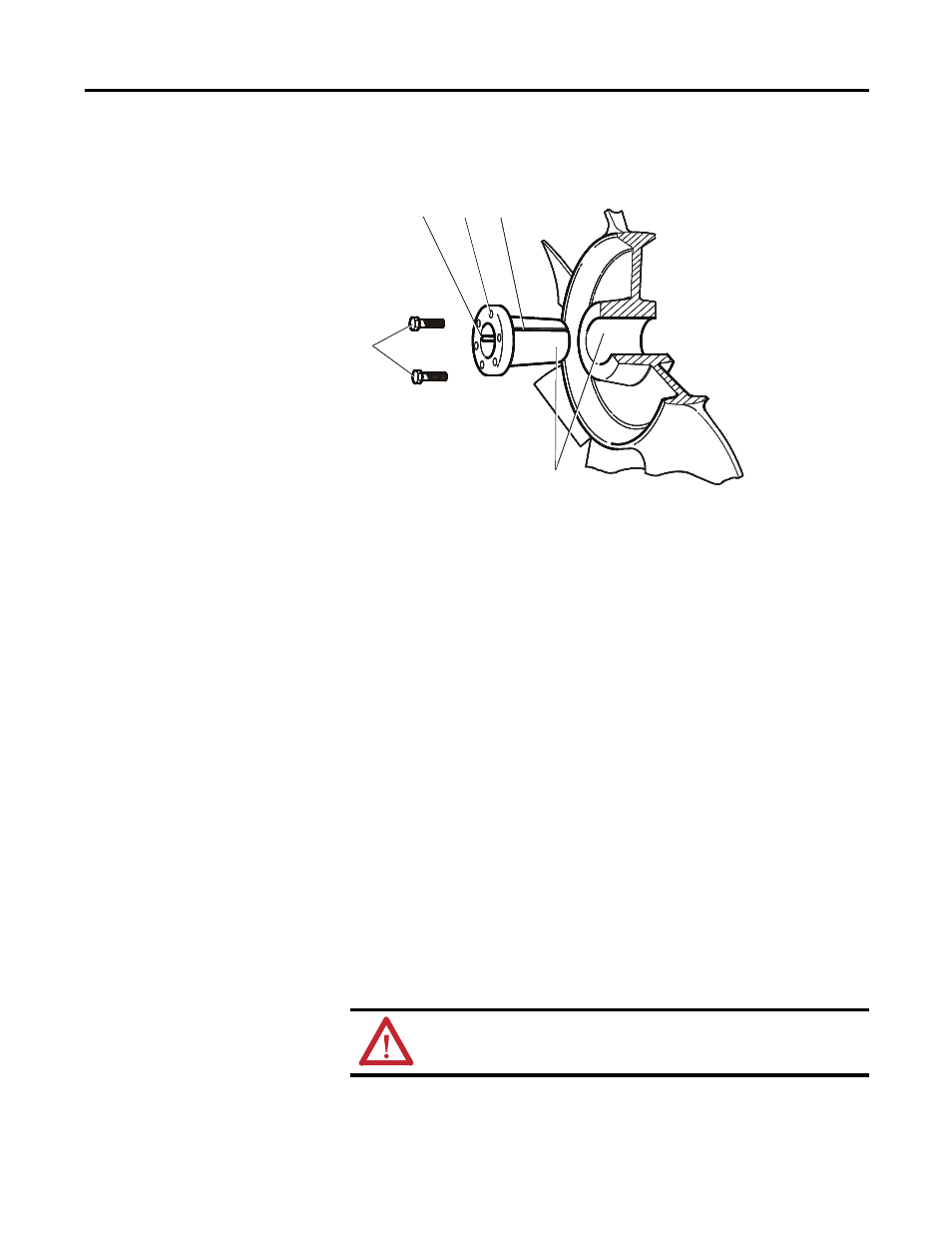

Figure 73 - Impeller Removal

1. Record the distance from the end of the motor shaft to the bushing. The

new impeller must be installed in the same location. Failure to do so will

result in gaps between the impeller and the intake ring resulting in loss of

air flow, or rubbing of the impeller against the inlet ring or motor assembly

during operation.

2. Remove both cap screws from the bushing. The impeller or bushing may

fall as screws are loosened.

3. Thread the cap screws by hand into the two threaded holes in the bushing

flange.

4. Tighten each bolt part of a turn successively, to push the impeller off the

bushing. Screwing down the cap screws into these holes will force the

bushing away from the impeller hub, releasing the compression on the

shaft. Be careful that the impeller does not fall as the clamping force is

released.

5. Pull the bushing off the shaft and remove the impeller. If the assembly has

been in place for some time, it may be necessary to use a wheel puller to

remove the bushing. Never use a wheel puller on the impeller.

ATTENTION: Do not lubricate capscrews, bore, or bushing barrel, as this

will hinder clamping force of the bushing on the shaft and the impeller

bore.

A

B

C

D

E

A – Taper surfaces

B – Capscrews

C – Split in Taper Bushing

D – Key

E – Threaded Hole for Separating Tapers

DO NOT LUBRICATE

CAPSCREWS, BORE

OR BUSHING BARREL

A

B

C

D

E

A

B

C

D

E

A – Taper surfaces

B – Capscrews

C – Split in Taper Bushing

D – Key

E – Threaded Hole for Separating Tapers

DO NOT LUBRICATE

CAPSCREWS, BORE

OR BUSHING BARREL