Flash memory transfers, Flash memory transfers on – Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - ForGe Control (PanelView 550) User Manual

Page 238

238

Rockwell Automation Publication 7000-UM151E-EN-P - January 2013

Chapter 5 Drive Programming and Parameters

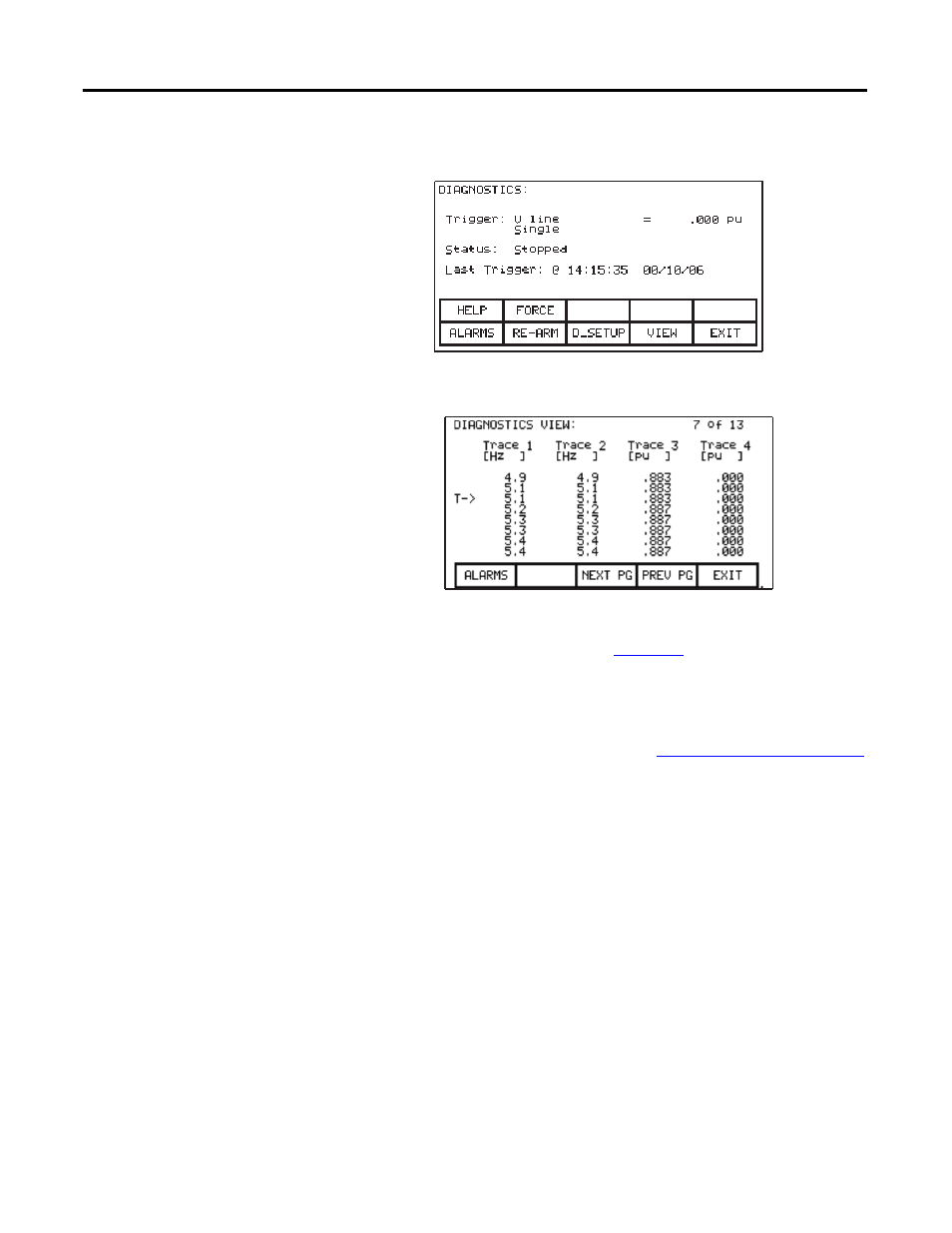

In continuous mode, the capture stops when you press [F9] to view the buffers.

Figure 228 - Diagnostic stopped

Figure 229 - View the Trend Buffer(s)

Initially, the trend view screen (similar to

) identifies the trigger point

by the “T ->”. To view data either side of the trigger point, press [F8] or [F9].

Changes made to the diagnostic list setup are not permanent until you save them

to the NVRAM. The interface will prompt you on exiting the DIAGNOSTICS

screen to save the changes to NVRAM. Refer to

for further details.

Flash Memory Transfers

The drive uses flash memory to store data in a stable format that is it is not lost

when power is disrupted. The operator interface contains flash memory in two

forms. The first is built into the operator interface, and stores the interface’s

firmware and drive parameters. You can also store this information on a

removable flash memory card.

This second form of (removable) flash enables you to physically transfer data

from one drive to another drive. All files on the flash card use a DOS format,

readable or writable by any PC containing a PCMCIA drive. PowerFlex 7000

drives support flash memory cardsharp the following INTEL memory chips:

• - 28F010

• - 28F020

• - 28F008SA

• - 28F016SA.