Output calibration – Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - ForGe Control (PanelView 550) User Manual

Page 108

108

Rockwell Automation Publication 7000-UM151E-EN-P - January 2013

Chapter 3 Component Definition and Maintenance

Output Calibration

Ensure the output of the supply is 56V DC.

There is a potentiometer on the top of the power supply that adjusts the 56 Volt

DC output for the power supply. Isolate the output of the power supplies;

multiple supplies in series will affect your measurements. With the control power

on and the output of the AC/DC Converter isolated from the drive control,

adjust the potentiometer until the output equals 56 volts DC. Perform this test

on each power supply. When all adjustments are complete, reconnect the power

supply to the circuit and re-measure the output. Readjust if necessary.

If it is not possible to maintain 56 V DC, the power supply may be faulty.

1. Ensure control power has been isolated and locked out.

2. Disconnect the terminals at the unit.

3. Remove the four M6 bolts per

4. Extract the power supply complete with bracket from the drive.

5. Remove the bracket(s) from the failed power supply (four M4 screws and

nylon shoulder washers).

6. Attach bracket to replacement power supply. Ensure the Black

Insulation(s) is between the AC/DC power supply and the mounting

plate(s).

7. Repeat Steps 5, 4, 3, 2 and 1 in this order to replace the unit.

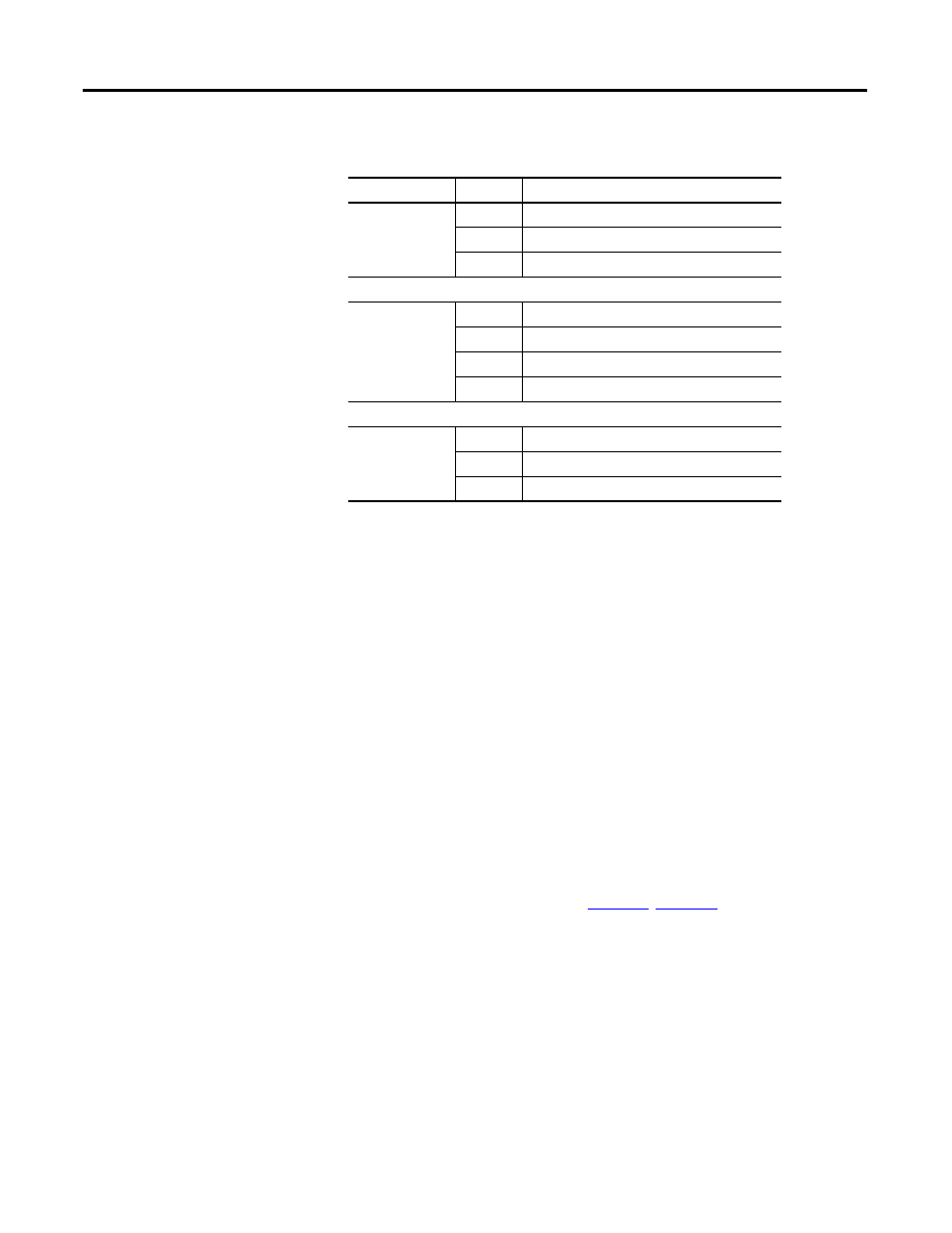

PIN#

LABEL

P1-AC input

1

EARTH

2

LINE

3

NEUTRAL

P2-DC output

1

+56V

2

+56V COMM

3

+56V

4

+56V COMM

P3-FAIL output

3

DC POWER FAIL (OUTPUT POWER GOOD)

15

CURRENT SHARING

14

DC POWER FAIL COMMON