Hydraulic system connection – JLG X23J - X700AJ Service Manual User Manual

Page 86

SECTION 3 - CHASSIS & TURNTABLE

3121448

– JLG Lift –

3-59

Hydraulic system connection

12. Make sure that the entire hydraulic system meets

the cleaning standard as given in level 9 according

NAS 1638 or 22/18/15 ISO/DIS 4406.

INFORMATION

CLEAN HOSES THOROUGHLY PRIOR TO CONNEC-

TION AND REMOVE ANY INTERNAL OBSTRUCTIONS.

PREVENT ANY FOREIGN PARTICLES FROM GET-

TING INTO THE HOSES BY REMOVING THE PLASTIC

C A P S O N L Y A T T H E T I M E O F T H E A S S E M B L Y.

AFTER HOSES ARE CONNECTED TO THE MOTOR,

FLOW THE HYDRAULIC CIRCUIT AND FILTER THE

OIL FROM ALL THE PARTICLES THAT MAY HAVE

CONTAMINED IT.

13. Clean the surface to be connected on the hydraulic

motor.

INFORMATION

ONLY WHEN IT IS NECESSARY TO ATTACH PIPES,

REMOVE THE PLASTIC CAPS PROTECTING THE

CONNECTIONS, THIS WILL ENSURE THAT NO FOR-

EIGN BODY GOES INSIDE THE HYDRAULIC MOTOR.

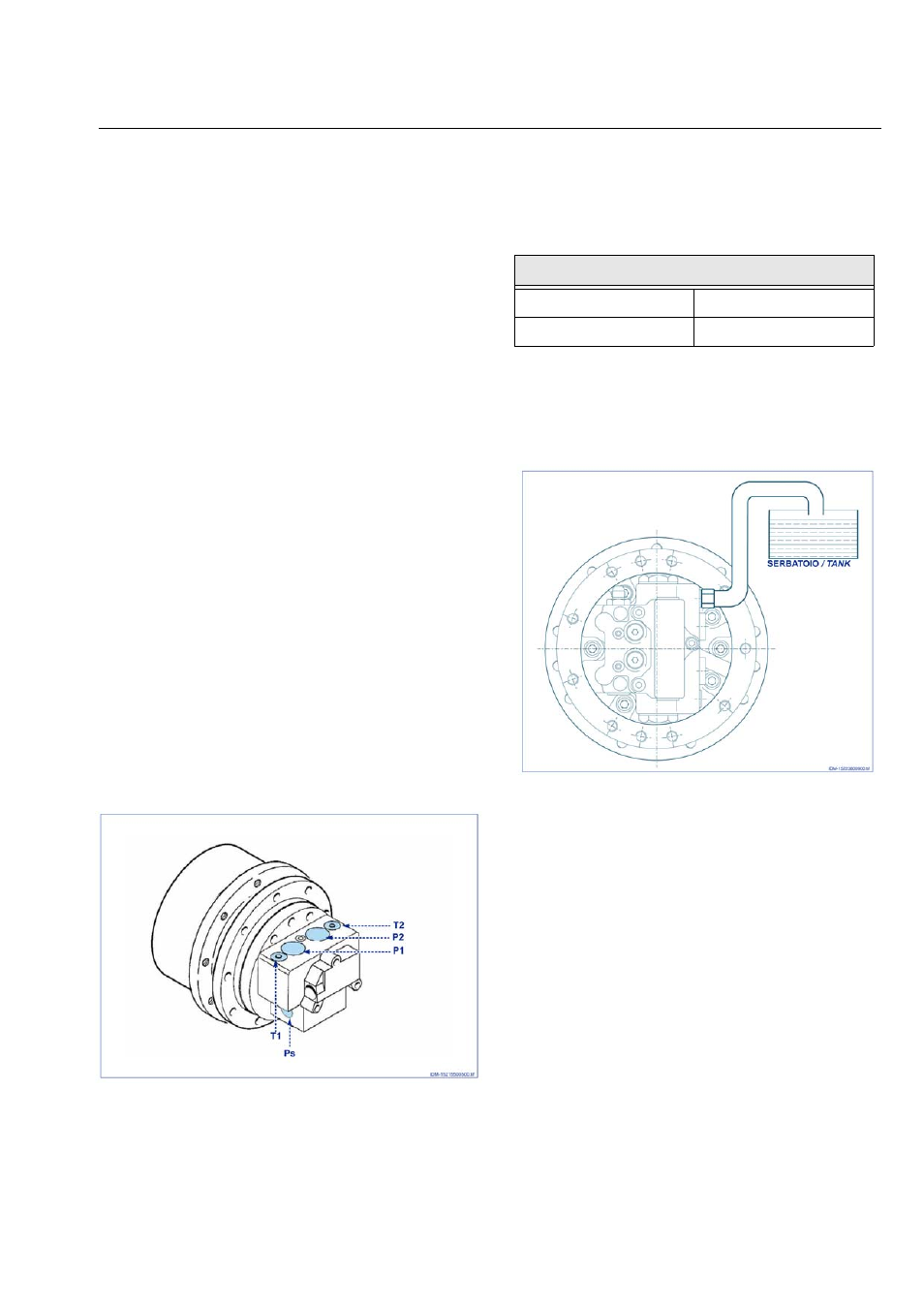

14. Pipe the hydraulic motor as shown below (for pipe

sizes and dimensions refer to the installation draw-

ing).

- Main ports: P1-P2

- Drain ports: T1-T2

- Two speed control port: Ps

Figure 3-160.

The drain pressure must be lower than the values shown

below.

Drain pipe must be directly and independently connected

to the tank. Drain port must be located on the upper side

of the motor.

Figure 3-161.

Motor drain pressure

Continuous running

Less than 1 bar

Max. intermittent

Less than 5 bar