Troubleshooting – JLG X23J - X700AJ Service Manual User Manual

Page 131

SECTION 3 - CHASSIS & TURNTABLE

3-104

– JLG Lift –

3121448

Troubleshooting

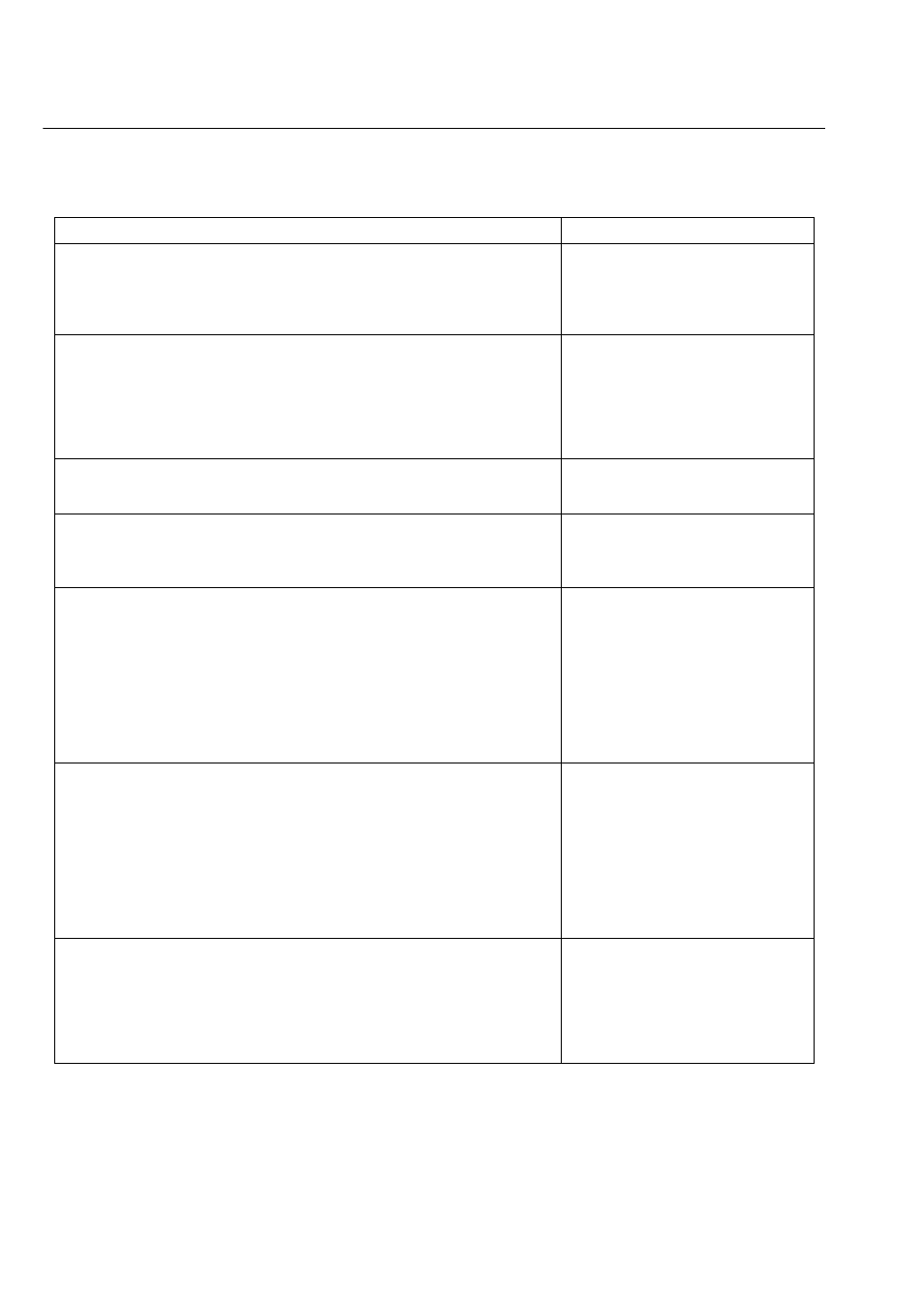

Condition

Cause

Correction

Motor will not turn

No oil

Pomp broken

Relief valve stuck open or set too low

Fill reservoir to proper oil level.

Replace pump.

Clean and free relief valve spool and

Adjust to proper setting.

Slow operation

Low oil viscosity

Worm pomp

Extremely high fluid temperatures

Relief setting too low

Use proper viscosity oil.

Repair or replace pump.

Increase reservoir size or add oil cooler.

Set relief valve for proper pressure.

Erratic motor operation

Relief setting too low

Air sucked in inlet side of pump

Set relief valve for proper pressure.

Tighten pipe fitting on pump inlet side.

Motor turns in wrong direction

Wrong piping

The valve timing is incorrect due to a

disassembling error.

Reverse the piping

Disassemble and reassemble the unit

and correct valve timing.

Fluid leakage

Loose bolts or plugs.

Scratched or abraded O-ring

Scratched or abraded X-ring

Scratched or abraded Floating seal

Tighten bolts and plugs by the correct

torque.

Replace the O-ring with a new one.

Replace the X-ring with a new one.

Lower the drain pressure until it is within

the allowable range.

Replace whole the Spindle / wheel

ass’y.

Abnormal sound

Air is remaining in the circuit and motor.

Pump cavitation.

Broken bearing

Bleed air completely.

Remove substance clogging the suc-

tion filter.

Enlarge the dia. Of the suction pipe of

the pump.

Raise the boost pump pressure.

Replace whole the Spindle / wheel

ass’y.

Bad changing Low speed

ÍÎ High speed

Remained pressure in the pilot line

The backpressure is high.

Orifice contaminated

Spool locked

Bleed remained pressure or decrease

remained pressure 0.5 MPa or below.

Lower the drain pressure 0.5 MPa or

below.

Remove the contamination.

Replace the Endcover ass’y.