JLG X23J - X700AJ Service Manual User Manual

Page 279

SECTION 3 - CHASSIS & TURNTABLE

3-252

– JLG Lift –

3121448

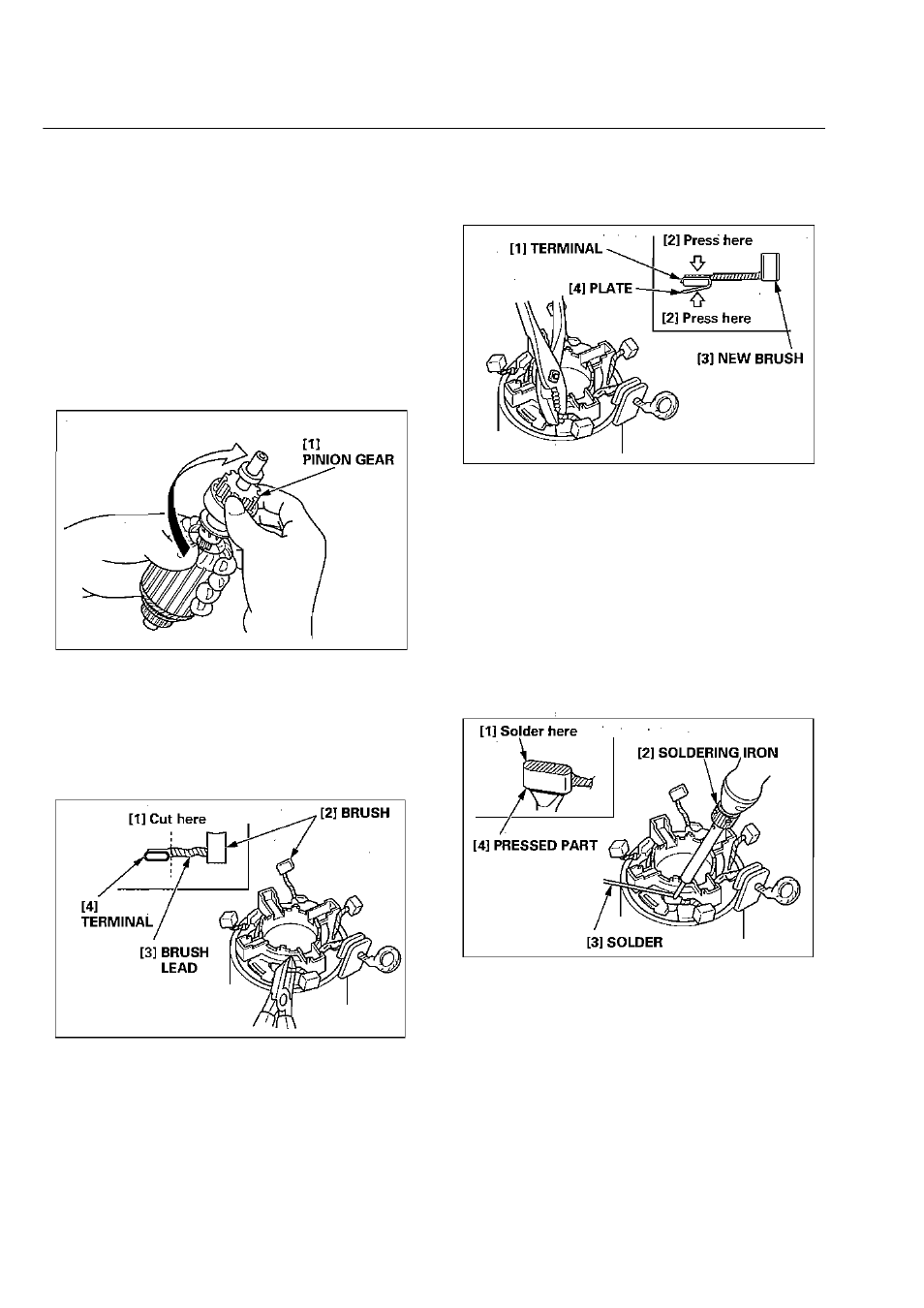

OVERRUNNING CLUTCH

1. Hold the pinion.gear.as shown and check that the

gear turns clockwise and slides smoothly. If neces-

sary, apply oil or replace the overrunning clutch.

2. Check the pinion gear for wear or damage and

replace if necessary.

3. If the pinion ear is worn or damaged, the flywheel

ring gear must be inspected.

BRUSH REPLACEMENT

4. Cut off the brush lead at the point shown and

remove the brush.

5. Remove the remaining brush lead and deposited

solder from the terminal.

6. Hold a new brush in the same direction of the

removed brush and put a new plate over the new

brush and terminal and press it using a pair of pliers

as shown.

7. Solder the plate on the terminal.

Before soldering heat the pressed part of the plate

well to make sure solder reaches the end of the

pressed part.

Prevent solder from flowing down the brush lead.

Do not allow solder lo run down onto the field wind-

ing of the yoke.

File the brush so that the brush and commutated

can fit using an every paper #500 or #601.