JLG X23J - X700AJ Service Manual User Manual

Page 205

SECTION 3 - CHASSIS & TURNTABLE

3-178

– JLG Lift –

3121448

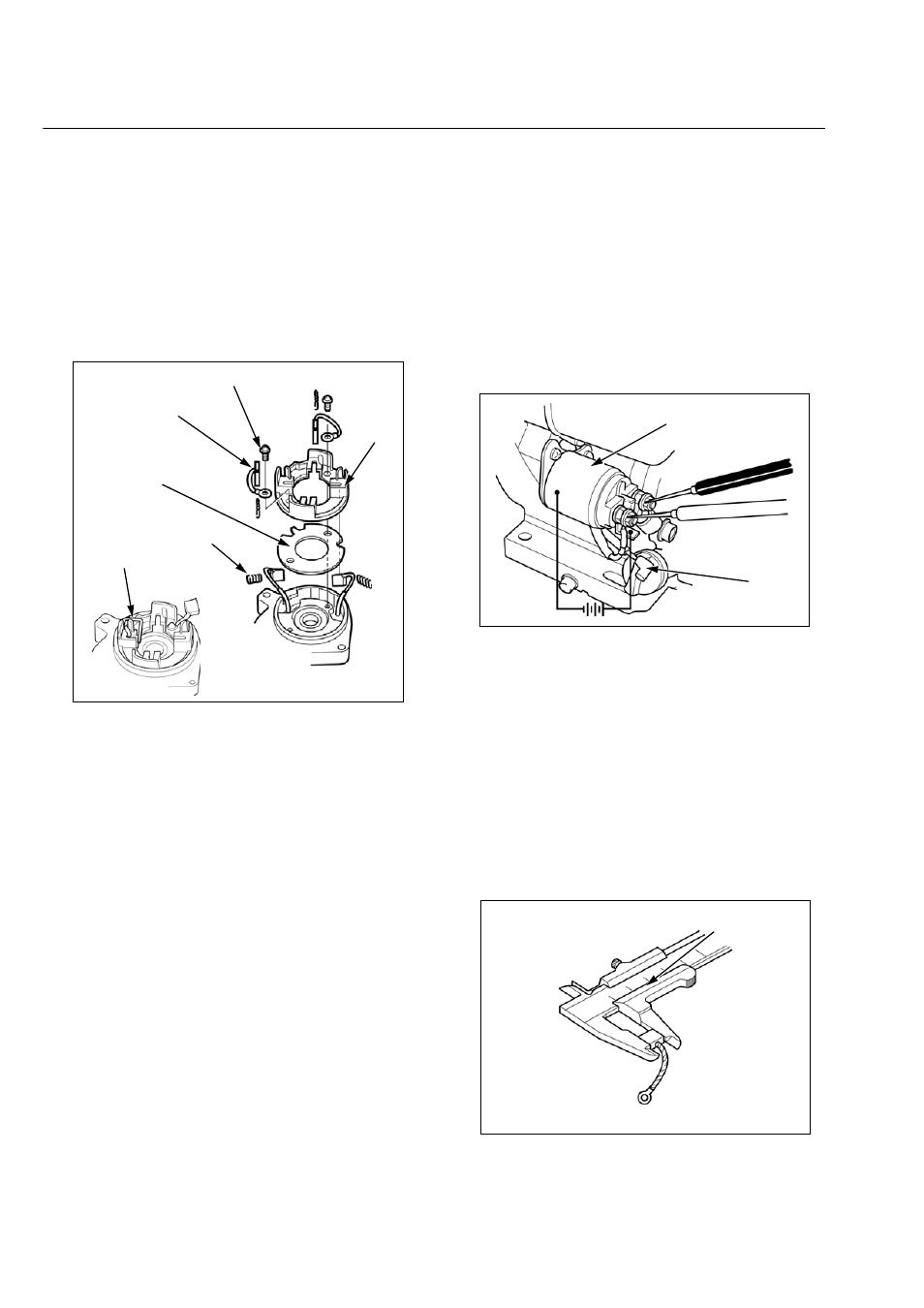

BRUSH HOLDER INSTALLATION

Note the installation direction.

Install the insulator (1), brush holder (2), negative brush

terminals (3), and two 4 x 14 mm screws (4) to the center

bracket as shown.

Install the brush springs (5) and brushes, and push the

brushes in the holders with a suitable wire (6) so that they

do not interfere with the commutator.

INSPECTION

PERFORMANCE TEST

Measure starter performance while cranking the engine.

STARTER MOTOR PERFORMANCE:

UNDER LOAD:CRANKING VOLTAGE:9.9 V

CRANKING CURRENT:103 A

ENGINE CRANKING SPEED:2,300 min-1 (rpm) min.

NO LOAD:CRANKING VOLTAGE:11.5 V

CRANKING CURRENT:31 A max.

• To get accurate results, the test must be conducted in

the normal ambient temperature.

• Battery: 55B24 (12 V 36 AH/5 HR)

• Battery cable: 15 sq. x 1.5 m (4.9 ft.) each for battery

positive cable and battery negative cable.

If the measurement is out of specification, disassemble

and inspect the starter motor.

STARTER SOLENOID

Remove the starter solenoid wire (1) from the starter sole-

noid (2).

Connect the positive (+) lead of a 12V battery to the sole-

noid terminal and the negative (-) lead to the solenoid

body. Measure the resistance between the battery and

starter motor terminals as shown.Continuity should exist

when the battery is connected and not exist when the bat-

tery is disconnected.

BRUSH LENGTH

Measure the brush length.

If the negative brush length is less than the service limit,

replace the brush and brush holder.

If the positive brush length is less than the service limit,

replace the center bracket and brush holder.

STANDARD:7.0 mm (0.28 in)

SERVICE LIMIT:3.5 mm (0.14 in)

(6)

(4)

(3)

(2)

(1)

(5)

(2)

(1)