Installation informations – JLG X23J - X700AJ Service Manual User Manual

Page 43

SECTION 3 - CHASSIS & TURNTABLE

3-16

– JLG Lift –

3121448

INSTALLATION INFORMATIONS

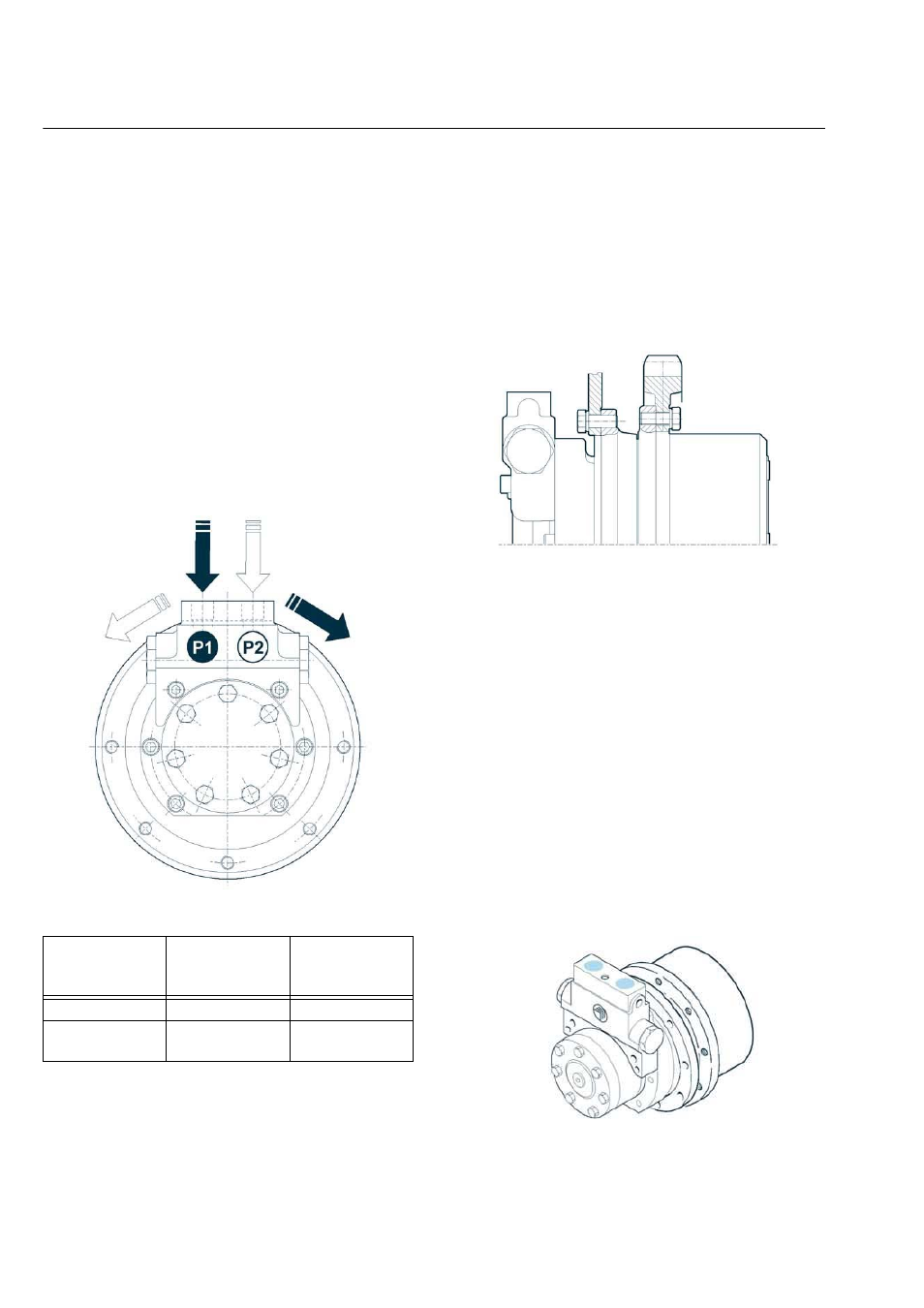

INSTALLATION PROCEDURE

Before proceeding with installation, follow the instructions

given below.

1. Properly clean the product by removing packaging

and all remains of protection padding.

2. Prepare the parts to be coupled using the installa-

tion drawing as a guide.

When assembling the track drive on the machine and con-

necting the hoses, follow instructions shown in below

sketch for proper direction of rotation.

Figure 3-24.

MOUNTING THE PRODUCT TO THE MACHINE

3. Move the gearmotor in the mounting area applying

lifting methods.

4. Install the motor gearbox connecting it to the

machine frame and to the sprocket using all screws

as the thread holes on to the flanges. Lock the

screws with the tightening torque shown in the fol-

lowing scheme.

Figure 3-25.

CONNECTIONS TO THE HYDRAULIC SYSTEM

5. Make sure that the entire hydraulic system meets

the cleaning standard as given in level 9 according

NAS 1638 or 18/15 ISO/DIS 4406.

6. Clean the surface to be connected on the hydraulic

motor.

INFORMATION

ONLY WHEN IT IS NECESSARY TO ATTACH PIPES,

REMOVE THE PLASTIC CAPS PROTECTING THE

CONNECTIONS, THIS WILL ENSURE THAT NO FOR-

EIGN BODY GOES INSIDE THE HYDRAULIC MOTOR.

7. Pipe the hydraulic motor as shown below (for pipe

sizes and dimensions refer to the installation draw-

ing).

Main ports: P1-P2

Figure 3-26.

Oil port inlet

Oil port outlet

Direction of

rotation (view

from motor)

P1

P2

Clockwise

P2

P1 Counterclock-

wise