JLG X23J - X700AJ Service Manual User Manual

Page 374

SECTION 3 - CHASSIS & TURNTABLE

3121448

– JLG Lift –

3-347

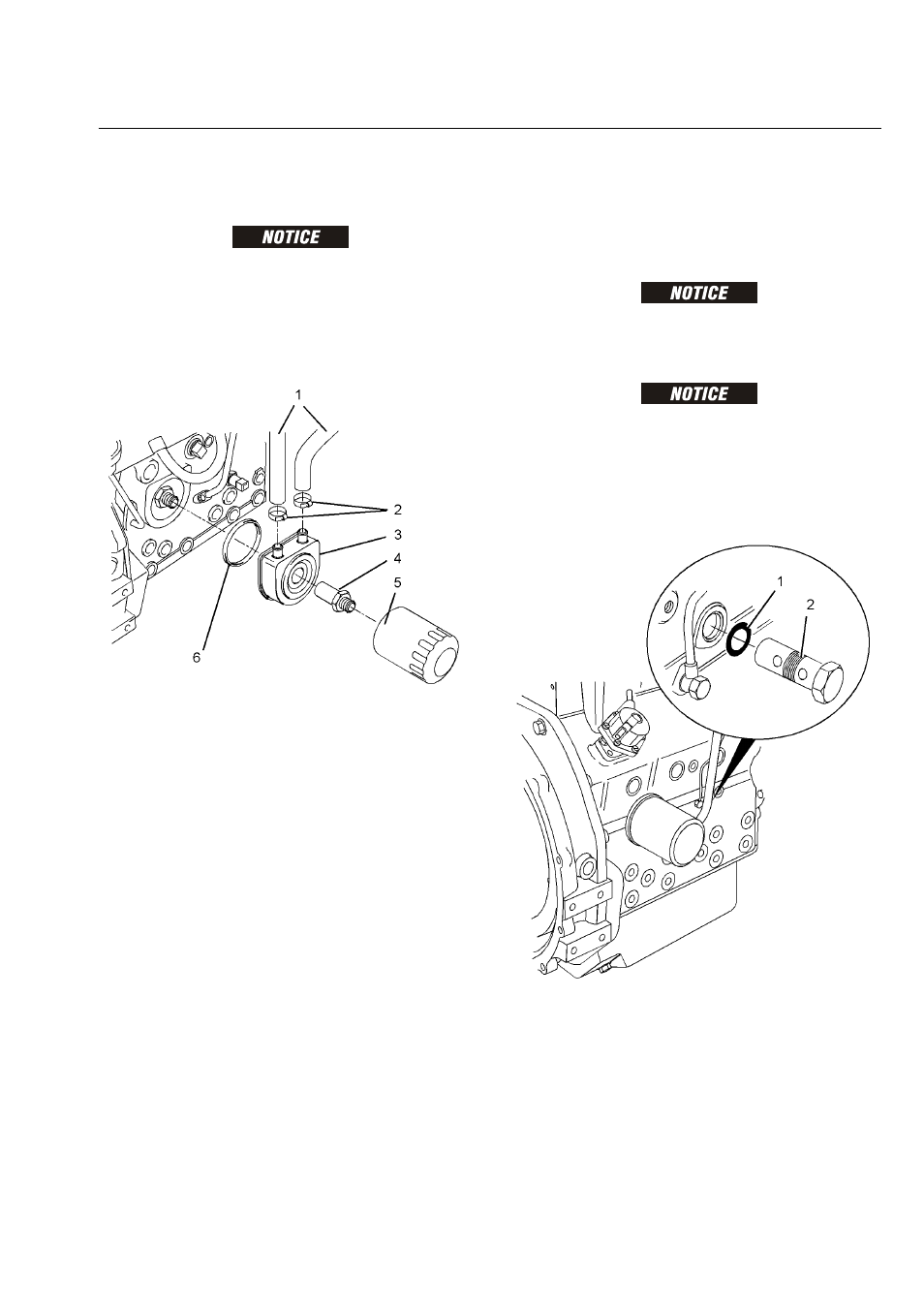

INSTALLATION PROCEDURE

KEEP ALL PARTS CLEAN FROM CONTAMINANTS. CONTAMI-

NANTS MAY CAUSE RAPID WEAR AND SHORTENED COMPONENT

LIFE.

7. Ensure that the oil cooler is clean and free from

damage. Clean the mating surfaces of the cylinder

block.

8. Install a new O-ring seal (6) to oil cooler (3). Position

oil cooler (3) on the cylinder block and install

adapter (4). Tighten adapter (4) to a torque of 34

N·m (25 lb ft).

NOTE: Ensure that the oil cooler is correctly oriented.

9. Connect hoses (1) to the coolant inlet and the cool-

ant outlet on oil cooler (3). Tighten hose clamps (2).

10. Install a new oil filter element (5).

11. Fill the cooling system to the correct level. Refer to

Operation and Maintenance Manual, “Cooling Sys-

tem Coolant - Fill” for the correct procedure.

12. Fill the engine oil pan to the correct level. Refer to

Operation and Maintenance Manual, “Engine Oil Fil-

ter - Change” for the correct procedure.

ENGINE OIL RELIEF VALVE - REMOVE AND

INSTALL

REMOVAL PROCEDURE

KEEP ALL PARTS CLEAN FROM CONTAMINANTS. CONTAMI-

NANTS MAY CAUSE RAPID WEAR AND SHORTENED COMPONENT

LIFE.

CARE MUST BE TAKEN TO ENSURE THAT FLUIDS ARE CON-

TAINED DURING PERFORMANCE OF INSPECTION, MAINTE-

NANCE, TESTING, ADJUSTING AND REPAIR OF THE PRODUCT.

BE PREPARED TO COLLECT THE FLUID WITH SUITABLE CON-

TAINERS BEFORE OPENING ANY COMPARTMENT OR DISASSEM-

BLING ANY COMPONENT CONTAINING FLUIDS. DISPOSE OF ALL

FLUIDS ACCORDING TO LOCAL REGULATIONS AND MANDATES.

1. Remove engine oil relief valve (2) from the cylinder

block.

2. Remove O-ring seal (1) from engine oil relief valve

(2).