JLG X23J - X700AJ Service Manual User Manual

Page 206

SECTION 3 - CHASSIS & TURNTABLE

3121448

– JLG Lift –

3-179

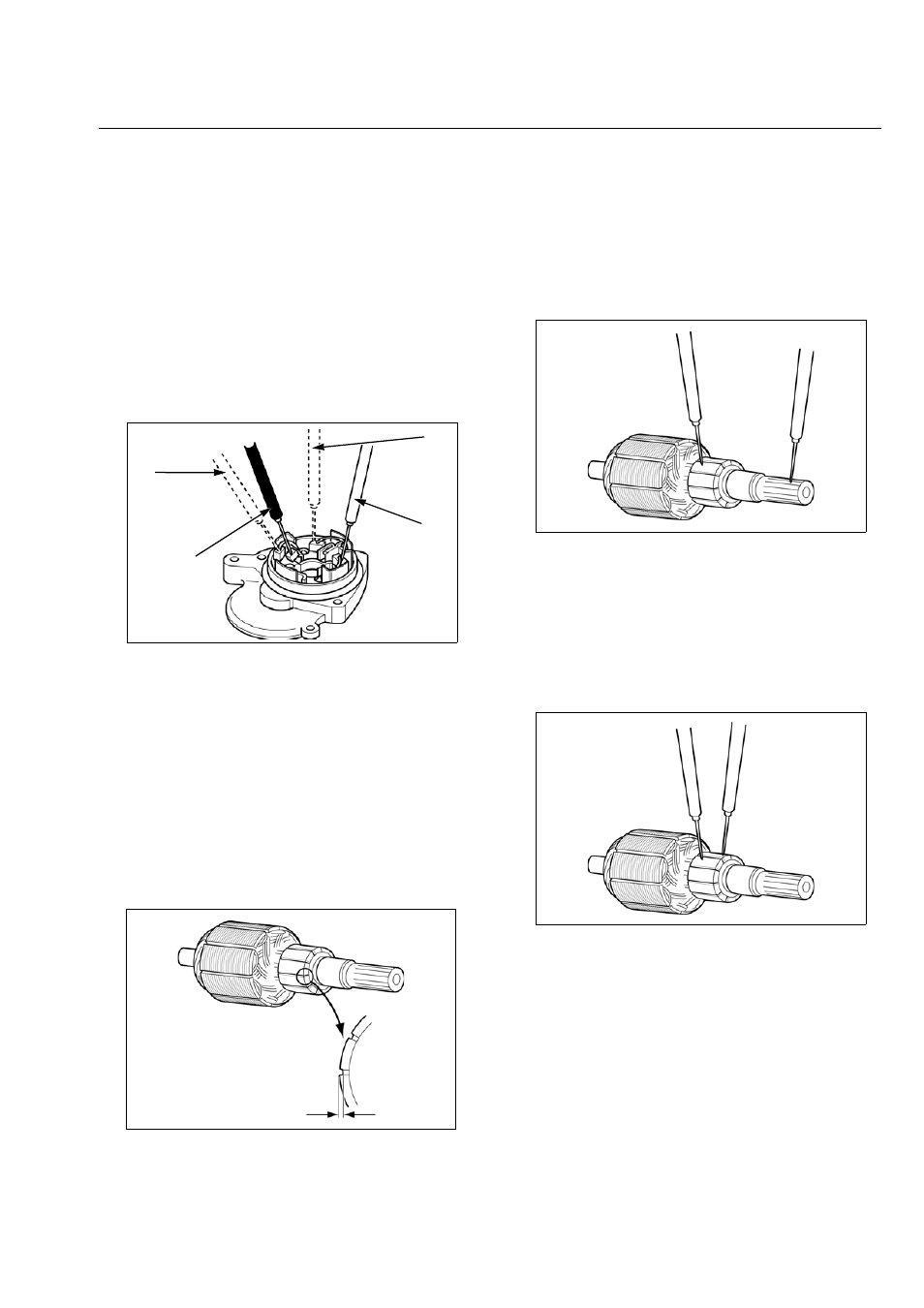

BRUSH CONTINUITY CHECK

Check for continuity between the positive (+) brushes(1)

and negative (-) brushes (2).

There should be continuity between both the positive-

brushes.There should be continuity between both the

negativebrushes.There should be no continuity from

either positive brush to either negative brush.

If the correct continuity of the positive (+) brushes is not

obtained, replace the center bracket (page 10-9).

If the correct continuity of the negative (-) brushes is not

obtain, replace the negative (-) brushes.

ARMATURE MICA DEPTH

Visually inspect the commutator surface for dust, rust,or

other damage. If necessary, wipe it with a clean lint-free

cloth. If rusted or damaged, dress with a fine emery cloth.

When the mica is clogged, or its depth is smaller than the

service limit value, recut the grooves using a hacksaw

blade or a small file.

STANDARD:1.0 mm (0.04 in)

SERVICE LIMIT:0.2 mm (0.01 in)

ARMATURE CONTINUITY CHECK -

COMMUTATOR TO SHAFT

Check for continuity between the commutator and the

armature shaft

Replace the armature if continuity exists between any of

the commutator segments and the armature shaft.

ARMATURE CONTINUITY CHECK -

COMMUTATOR SEGMENTS

Check for continuity between segments. If an open circuit

(no continuity) exists between any two segments, replace

the armature.

(1)

(1)

(2)

(2)