Maintenance informations – JLG X23J - X700AJ Service Manual User Manual

Page 46

SECTION 3 - CHASSIS & TURNTABLE

3121448

– JLG Lift –

3-19

FIRST START UP AND RUNNING IN

In this first stage it is advised to follow the measures given

below.

11. Bleed air from every part of the hydraulic circuit and

add oil in the tank if necessary.

INFORMATION

THE PRESENCE OF RESIDUAL AIR IN THE HYDRAU-

LIC CIRCUIT WILL MANIFEST ITSELF WITH THE

PRESENCE OF FOAM IN THE TANK AND WILL LEAD

TO A JERKING OF THE MOTOR AS WELL AS EXCES-

SIVE NOISE COMING FROM THE MOTOR AND THE

VALVES.

12. Start the gearmotor at a low speed and gradually

increase it after having verified that it is functioning

correctly without any noises or vibrations.

INFORMATION

DO NOT REACH MAXIMUM PRESSURE UNLESS THE

ENTIRE SYSTEM HAS BEEN FILTERED TO ELIMI-

NATE ANY PARTICLES OF DIRT THAT MAY BE PRES-

ENT.

During the running-in stage follow the steps given below.

13. Make sure that the speed and direction of rotation

are correct.

14. Make sure that the functioning is regular and without

any excessive noises and vibrations.

15. Make sure that the oil temperature does not exceed

60°C.

After having terminated this first running-in, follow the

steps given below.

16. Check that there are no oil leakages. If present, pro-

ceed to remove them.

17. Check that there are no other problems in general.

MAINTENANCE INFORMATIONS

PERIODIC MAINTENANCE

The gearmotor only requires the scheduled maintenance

procedures set out by the manufacturer (see Table

below).

Good maintenance will ensure an on going functioning in

time as well as maximum reliability.

Should irregularities in function arise, it will be necessary

to consult the troubleshooting checklist to find the most

adequate solution.

If unsuccessful, it may be necessary to disassemble par-

tially or completely the motor gearbox.

Table 3-4.

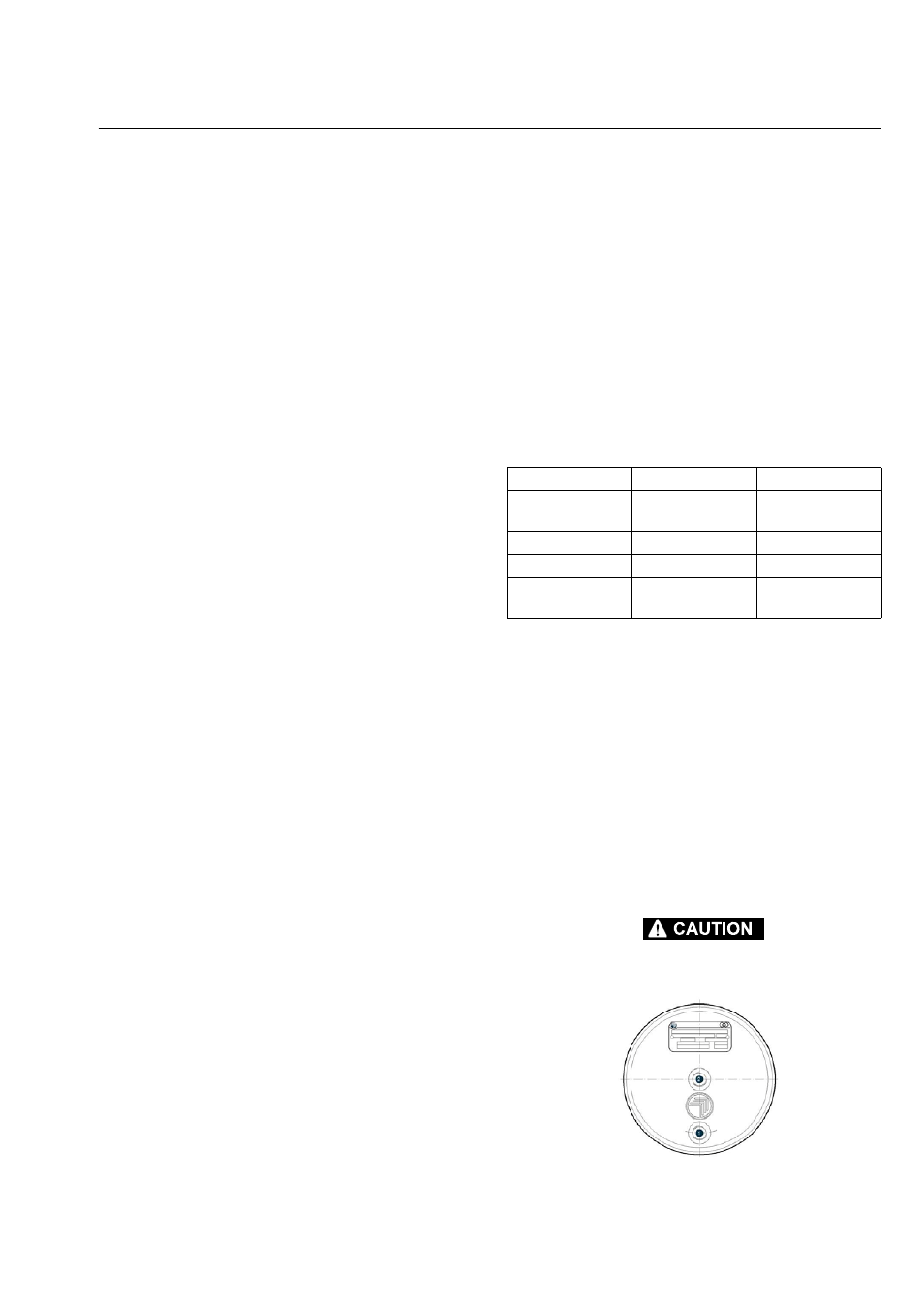

CHANGING THE LUBRICATING OIL

1. Place a large enough container (about 1 litre) under

the oil drain plug.

2. Unscrew the plug (2).

3. Unscrew the oil drain plug (1) and allow the oil to

drain. To facilitate the draining operation, it is better

to work with hot oil.

4. Wait a few minutes until all the oil is drained and

than proceed to screw on drain plugs (1-2).

5. Proceed with the oil fill-up following the procedures

given.

DO NOT DISPOSE OF THE OIL IN THE NATURAL ENVIRONMENT

BUT BE CAREFUL TO ELIMINATE IT IN COMPLIANCE WITH THE

RELATIVE RULES AND REGULATIONS THAT GOVERN LOCALLY.

Inspection

Frequency

Action

Tightening screws After the first 50

hours

Screws tighening

torque check

Oil level

Every 100 hours

Refill oil

1st oil change

At 150 hours

Oil replacement

Following oil

changes

Every 100 hours or

1year

Oil replacement