JLG X23J - X700AJ Service Manual User Manual

Page 139

SECTION 3 - CHASSIS & TURNTABLE

3-112

– JLG Lift –

3121448

Permissible deformation of the mounting structure,

under maximum load for series WD-H slew drives

IMPORTANT

AXIAL DEFLECTION, TILTING, RADIAL EXTENSION

(OR RADIAL CONTRACTION) OF THE MOUNTING

STRUCTURE UNDER MAX. LOAD CAUSES DEFORMA-

TION OF THE MOUNTING STRUCTURE.

SELECTING THE MOUNTING ELEMENTS

ONLY USE MOUNTING ELEMENTS OF THE CORRECT SIZE, NUM-

BER AND QUALITY. DO NOT REUSE BOLTS, NUTS, AND WASH-

ERS. USING UNSUITABLE MOUNTING ELEMENTS MAY CAUSE

THE BOLTED UNION TO FAIL AND THUS THE ENTIRE CONSTRUC-

TION TO FAIL.

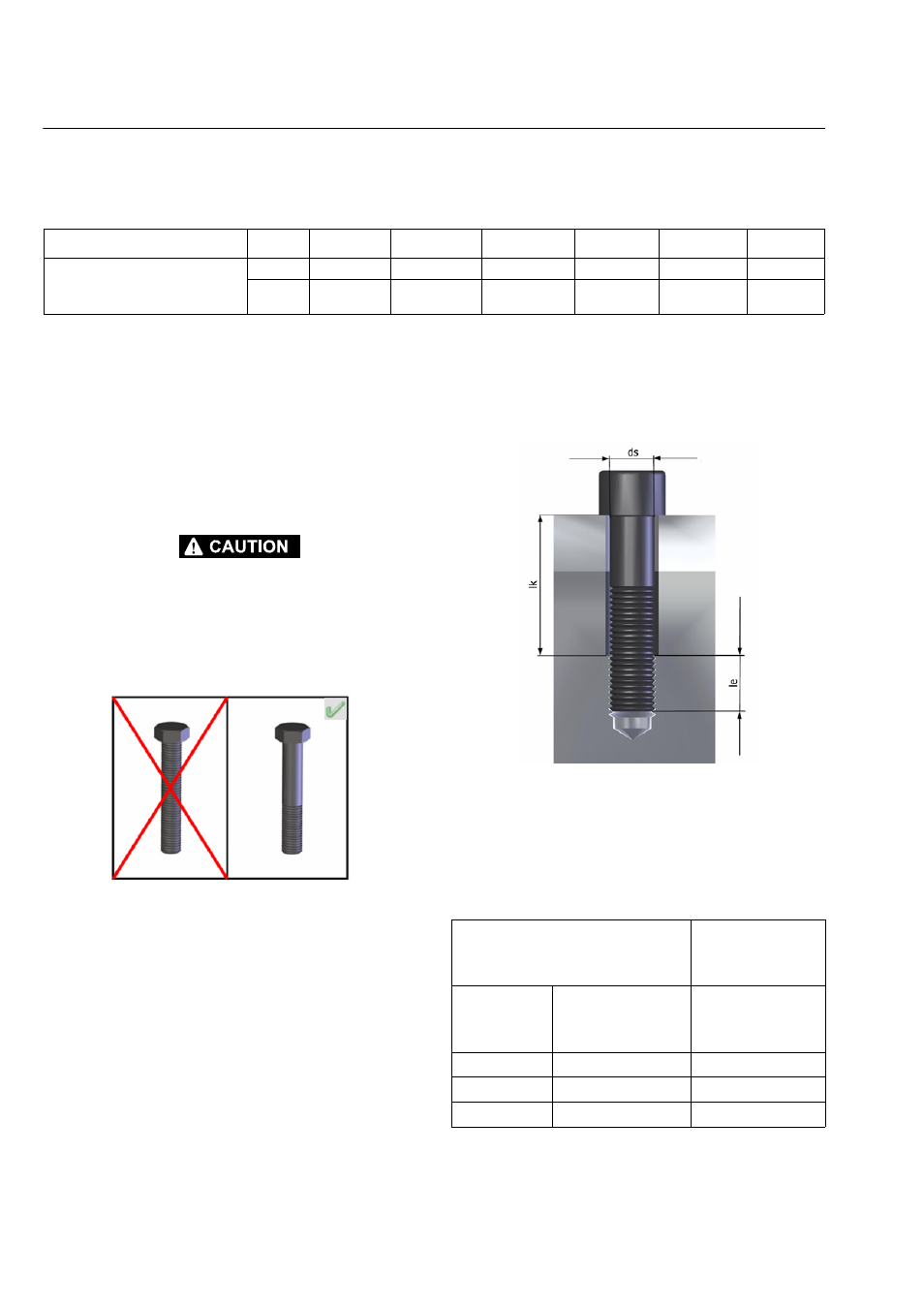

Figure 3-191. Do not use continuous thread

The function and service life, as well as the durability of

the bolted union are highly dependent on grip ratio, the

type of bolt, and the dimensions of the bolts. Conse-

quently select the mounting elements on the basis of the

following:

• Do not use any bolts with a fully threaded shaft.

• Only use new, quality class 10.9 (metric) bolts or SAE

Grade 8.

• Maintain the grip ratio (grip length to the diameter of

the bolt) of at least

≥

5 to maximum

≤

10.

• Select bolt length to ensure that the minimum insertion

depth is reached.

• If the permissible interfacial pressure is exceeded use

appropriate washers.

Figure 3-192. Mounting element

Minimum insertion depth depending on fracture

strength of the mounting structure

Size of the slew drive

≥

146

≥

220

≥

300

≥

373

≥

490

≥

625

Permissible deformation of the

mounting structure per support sur-

face

[mm]

0.10

0.11

0.12

0.13

0.15

0.16

[in]

0.0040

0.0044

0.0048

0.0052

0.0059

0.0063

Fracture strength Rm of the

mounting structure

Minimum

insertion depth

(le)

in N/mm²

in lbf/in²

Strength class

10.9 / Grade 8

500 to 700

72520 to 101525

le = 1.4*ds

700 to 900

101525 to 130535

le = 1.1*ds

over 900

over 130535

le = 0.9*ds