4 troubleshooting, Troubleshooting -11 – TOHO ELECTRONICS TTM200 User Manual

Page 242

48-7009-E

7-11

7.4 Troubleshooting

Check corresponding items listed below to abnormal operation of this product before requesting for a repair.

In case of no normal operation restored, contact TOHO’s sales department to return the product for a repair.

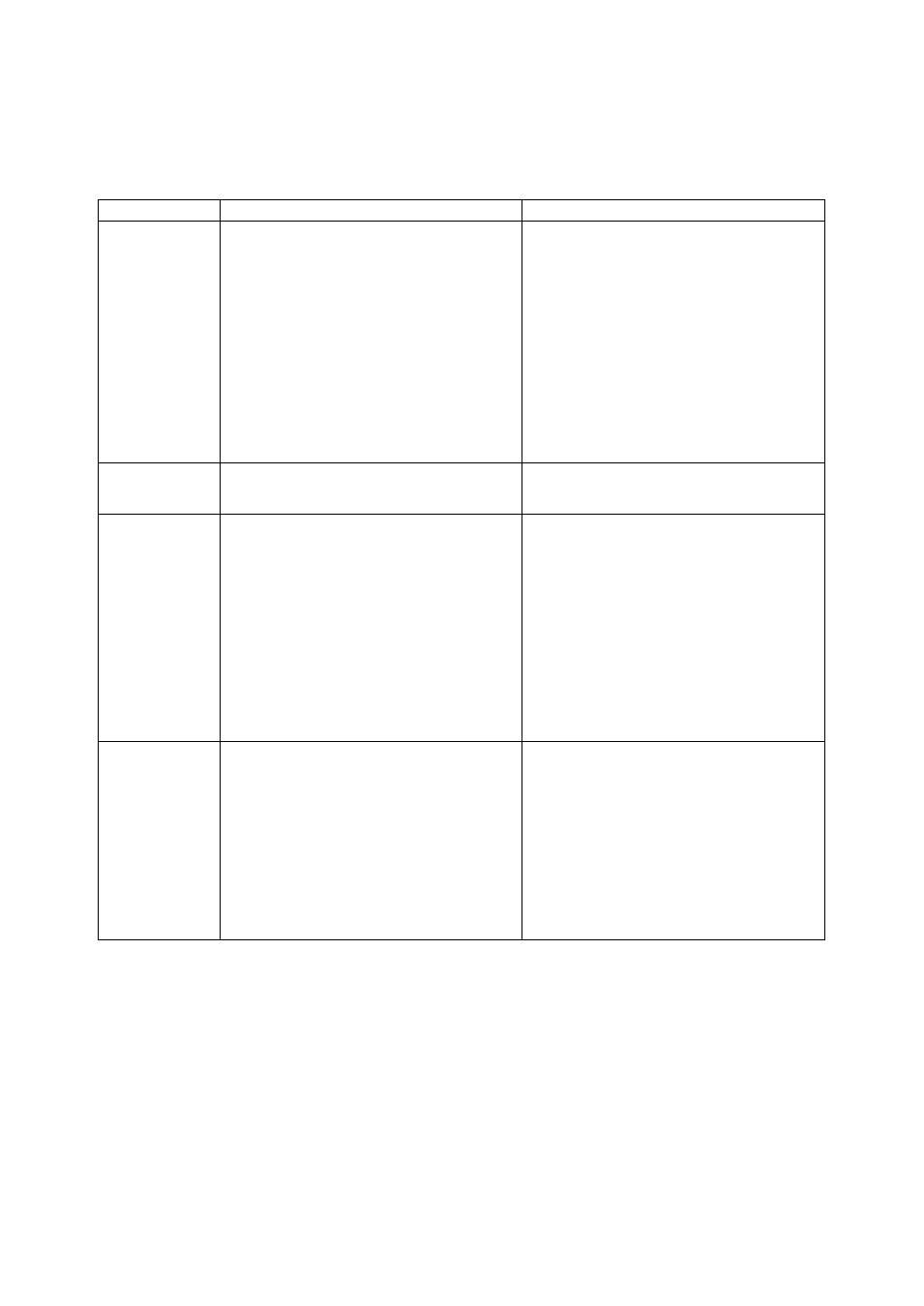

Symptom

Description

Check item

Too much

difference of

temperatures

(1) Input type does not match the one of the main

frame.

(2) Resistance temperature detector is not

properly connected.

(3) Resistance temperature detector is

disconnected or shorted.

(4) The product is affected by noise from the

power line due to wires for lead and power

supply being laid in the same tubing.

(5) Copper wire is used for connecting this

product with thermocouple.

(6) Input compensation (PV compensation) is not

properly set.

Setting at factory shipment is

“0 °C.”

(1) Check the sensor type and properly set the

input type on the main frame.

(2) Check the mounting location and polarity of

the resistance temperature detector to

properly connect it.

(3) Check the resistance temperature detector for

disconnection or short.

(4) Separately wire them.

(5) Connect lead wires of the thermocouple

directly to the product or use compensated

leads suited for the thermocouple.

(6) Enter the appropriate value for the input

compensation value.

No communication

possible

(1) Inappropriate communication software

(2) Use of non-recommended converter

(1) Check the software protocol for

inappropriateness.

(2) Check connection devices for abnormality.

No output

provided (no

turn-on)

(1) Control mode is set for READY.

At factory shipment, the setting is RUN.

(2) Target control operation is not set.

At factory shipment, the setting is “reverse

operation.”

(3) Too large a sensitivity value is set for the

ON/OFF operation.

At factory shipment, the set

ting is “1.0 °C.”

(4)

The setting is “control stop” due to assignment

of the function key for “control start/stop.”

(5) Setting value is set with incorrect decimal

point position without noticing the position

being shown as “0.0.”

(1) Set the control mode to RUN in the setting

mode of SET 4, item 5. Currently, display

lamp is lighting as RDY, indicating the state of

control stop.

(2)

Check the settings of “reverse operation

(heating)” and “forward operation (cooling).”

(3) Set an appropriate value for the adjustment

sensitivity.

(4) Have the state of control start by a single

press of the FUNC key.

(5) Check settings of the decimal point position

and value.

No rise in

temperature

(1) Target control operation is not set.

At factory ship

ment, the setting is “reverse

operation.”

(2) Heater is disconnected or deteriorated.

(3) Insufficient capacity of heater.

(4) Cooling is operating.

(5) An overheat protector for a peripheral device

is operating.

(1)

Check the settings of “reverse operation

(heating)” and “forward operation (cooling).”

(2) Check the heater for disconnection or

deterioration. Consider the use of heater

disconnection alarm (option) to detect

abnormality.

(3) Check that the heater has a sufficient heating

capacity.

(4) Check the operation for cooling being

effective.

(5) Set the temperature setting of the overheat

protector higher than that of this product.