5 explanation of the program run function, Explanation of the program run function -47 – TOHO ELECTRONICS TTM200 User Manual

Page 117

48-7009-E

5-47

5.5 Explanation of the program run function

■ The digital controller TTM-200 Series can provide a simple program controller. This chapter

explains the program run of TTM-200 Series.

• A program run of this product is established by automatically controlling “bank function” and

“program step function.” The process flow for establishing a program run is described below.

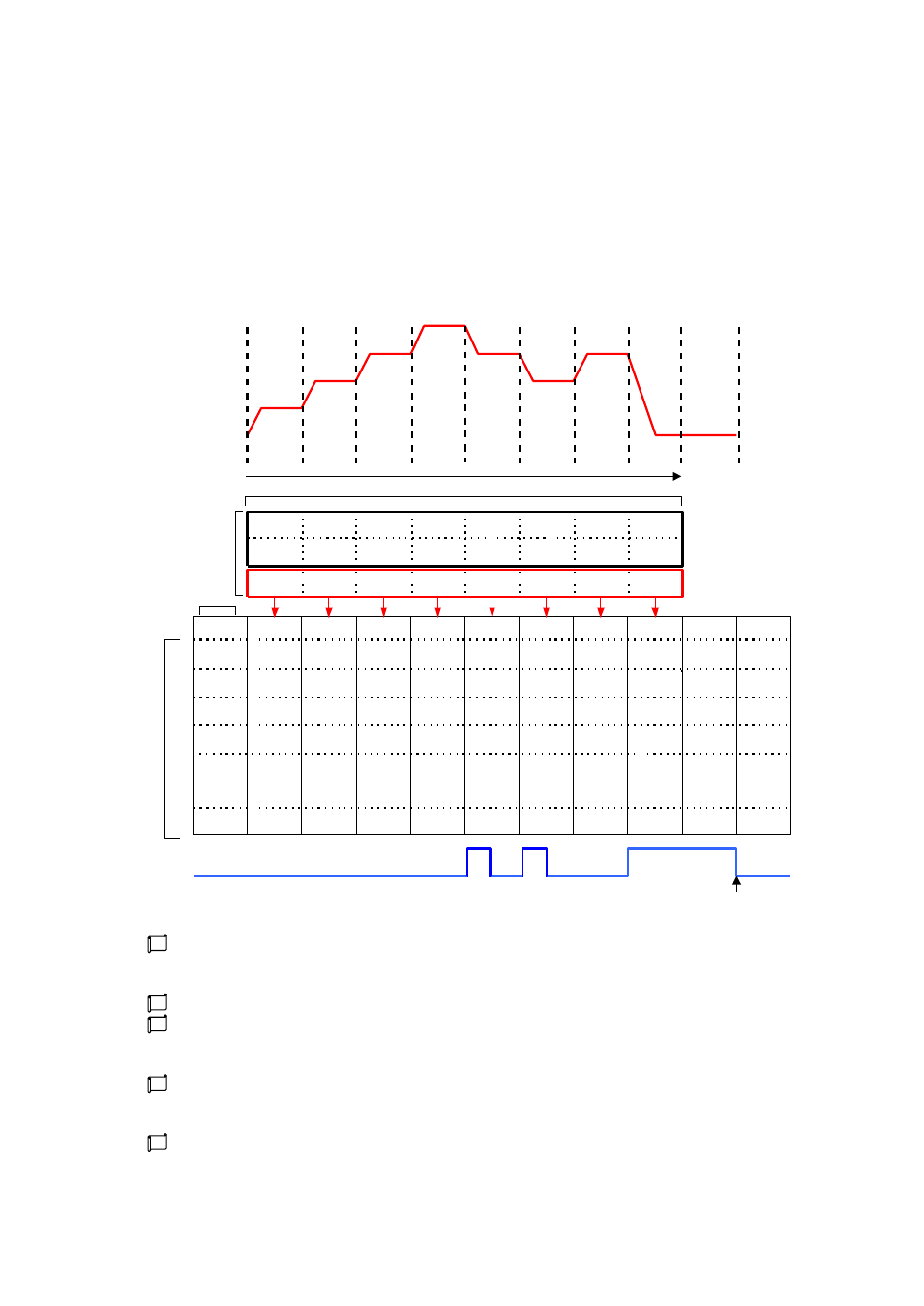

■ Program run operation explanation diagram

STEP1

STEP2

STEP3

STEP4

STEP5

STEP6

STEP7

STEP8

SV1

50℃

TIM1

00:30

ST1BK

BANK1

BANK1

RMP

10

P1

4.0

・

・

・

o2F

I

20

D

5

SV2

100℃

TIM2

00:40

ST2BK

BANK1

BANK1

RMP

10

・

・

・

o2F

SV3

150℃

TIM3

00:50

ST3BK

BANK1

BANK1

RMP

10

・

・

・

o2F

SV4

200℃

TIM4

01:00

ST4BK

BANK1

BANK1

RMP

10

・

・

・

o2F

SV5

150℃

TIM5

00:30

ST5BK

BANK2

BANK2

RMP

5

・

・

・

o2F

TIMER ON

DELAY

SV6

100℃

TIM6

00:40

ST6BK

BANK2

BANK2

RMP

5

・

・

・

SV7

150℃

TIM7

00:50

ST7BK

BANK1

BANK1

RMP

10

・

・

・

o2F

SV8

20℃

TIM8

00:10

ST8BK

BANK3

BANK3

RMP

30

・

・

・

o2F

RUN OUT

BANK0

RMP

P1

3.0

M

AX

.

1

6

P

AR

AM

E

T

E

R

・

・

・

o2F

END OUT

I

0

D

0

BANK0

RMP

・

・

・

o2F

END OUT

START

OPERATION

END

OPERATION

END

PV

BANK0

RMP

M

AX

1

6

パ

ラメ

ー

タ

・

・

・

o2F

END OUT

OPERATION

STOP

STOP

OPERATION

STOP OPERATION

P1

2.0

I

10

D

2

P1

3.0

I

0

D

0

P1

3.0

I

0

D

0

P1

4.0

I

20

D

5

P1

4.0

I

20

D

5

P1

4.0

I

20

D

5

P1

4.0

I

20

D

5

P1

2.0

I

10

D

2

P1

2.0

I

10

D

2

SET22

SETTING

VALUE

MAX. 8 STEPS

SET20

SETTING

VALUE

STEP SV SETTING

STEP TIME SETTING

STEP BANK SETTING

o2F

TEMP. CHANGE PATTERN

REFER

1BANK

OPERATION

STOP

OUTPUT EXAMPLE

TIMER ON

DELAY

o2F

A certain pattern of a status to be changed, such as temperature, is developed. The diagram

above shows an example of a temperature change pattern. To automatically change this pattern,

it is divided into the smallest units referred to as STEP.

Set the auto run sequence of a STEP to the SET 22 “program step” parameter.

For “step bank setting” of SET 22, SET 20 “bank function” is referred. With this reference,

operations of “input, output, timer output, event input/output, control parameters, etc.” for each

step are determined.

Parameters necessary for such control as “input,” “output,” “timer output,” or “event” are set.

The steps during an auto run sequence are automatically switched by the sequence, and banks set

with control parameters are also switched. This mechanism provides a program run.

This product allows a program run in eight steps at most.

o2F OUTPUT EXAMPLE

MAX.

1

6

P

AR

AME

T

ER