Responding to process and deviation alarms, Resetting a process or deviation alarm – Watlow CLS200 User Manual

Page 181

CLS200 Series User’s Guide

Chapter 9:Troubleshooting and Reconfiguring

Doc.# 0600-3050-2000

Watlow Anafaze

165

Responding to Process and Deviation Alarms

In a heating application, a low process or low deviation

alarm may indicate one of the following:

•

The heater has not had time to raise the temperature.

•

The load has increased and the temperature has fall-

en.

•

The control status is set to manual instead of automatic.

•

The heaters are not working due to a hardware failure.

•

The sensor is not placed correctly and is not measuring

the load’s temperature.

•

The deviation limit is too narrow.

•

The system is so poorly tuned that the temperature is

cycling about setpoint by more than the alarm limit.

NOTE!

In cooling applications, similar issues cause

high process and high deviation alarms.

In a heating application, a high process alarm or high devi-

ation alarm may indicate one of the following:

•

The setpoint and high process limit have been lowered

and the system has not had time to cool to within the

new alarm limit.

•

The control status is set to manual and the heat out-

put is greater than 0%.

•

The load has decreased such that the temperature has

risen.

•

The heater is full-on due to a hardware failure.

•

The system is so poorly tuned that the temperature is

cycling about setpoint by more than the alarm limit.

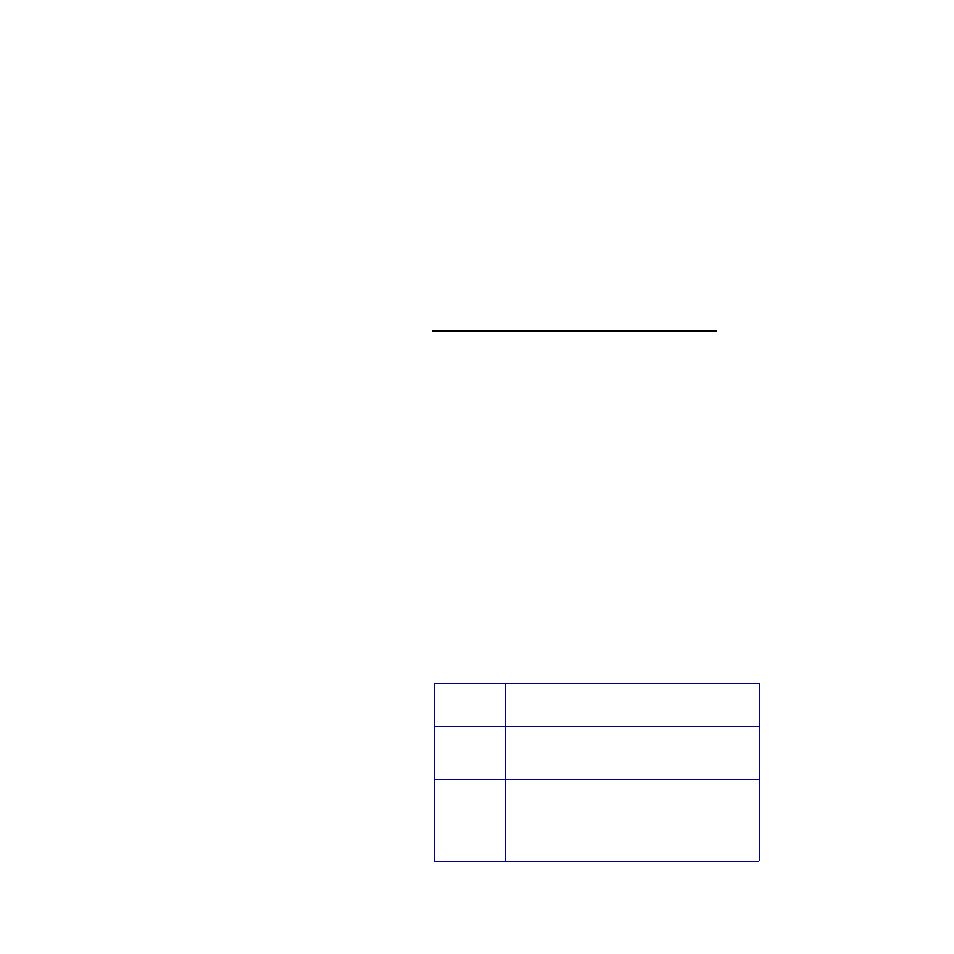

Resetting a Process or Deviation Alarm

Your response to an alarm depends upon the alarm type

setting, as explained in Table 9.2 below.

Table 9.2

Operator Response to Alarms

Alarm

Type

Operator Response

Control

The operator does not need to do anything.

The alarm clears automatically when the pro-

cess variable returns within limits.

Alarm

Acknowledge the alarm by pressing

ALARM

ACK on the controller or by using software.

The alarm clears after the process variable

returns within the limits and the operator has

acknowledged it.