Watlow CLS200 User Manual

Page 139

CLS200 Series User’s Guide

Chapter 6: Enhanced Features

Doc.# 0600-3050-2000

Watlow Anafaze

123

3.

Press

BACK several times until the normal loop display

appears. The output percentage of loop 1 will now con-

trol the setpoint of loop 2.

To verify that cascade is working as expected, you would

follow these steps:

1.

Set loop 1 to MANUAL and the OUTPUT to 0%. Loop 2 set-

point should equal 150 (BASE SP).

2.

Adjust loop 1 MANUAL OUTPUT to 50%. Loop 2 setpoint

should equal 170 (BASE SP + 50% of HT SPAN)

3.

Adjust loop 1 MANUAL OUTPUT to 100%. Loop 2 set-

point should equal 190 (BASE SP + HT SPAN).

4.

To complete the cascade setup, both loop 1 and loop 2

must be configured for inputs, outputs, and alarms.

In addition, the PID parameters of loop 1 must be tuned to

produce the desired effect for the application on the set-

point of loop 2. For a cascade control application that uses

the secondary loop for PID control, loop 1 typically uses

only proportional mode. This must be set for the amount of

change in the process variable to cause a 100% change in

the output level.

The proportional band is selected so the setpoint of the sec-

ondary loop has the desired relationship to the process

variable of the primary loop. In this application, the pro-

portional band (PB) of the primary loop is set to 10˚ F and

the integral and derivative are turned off.

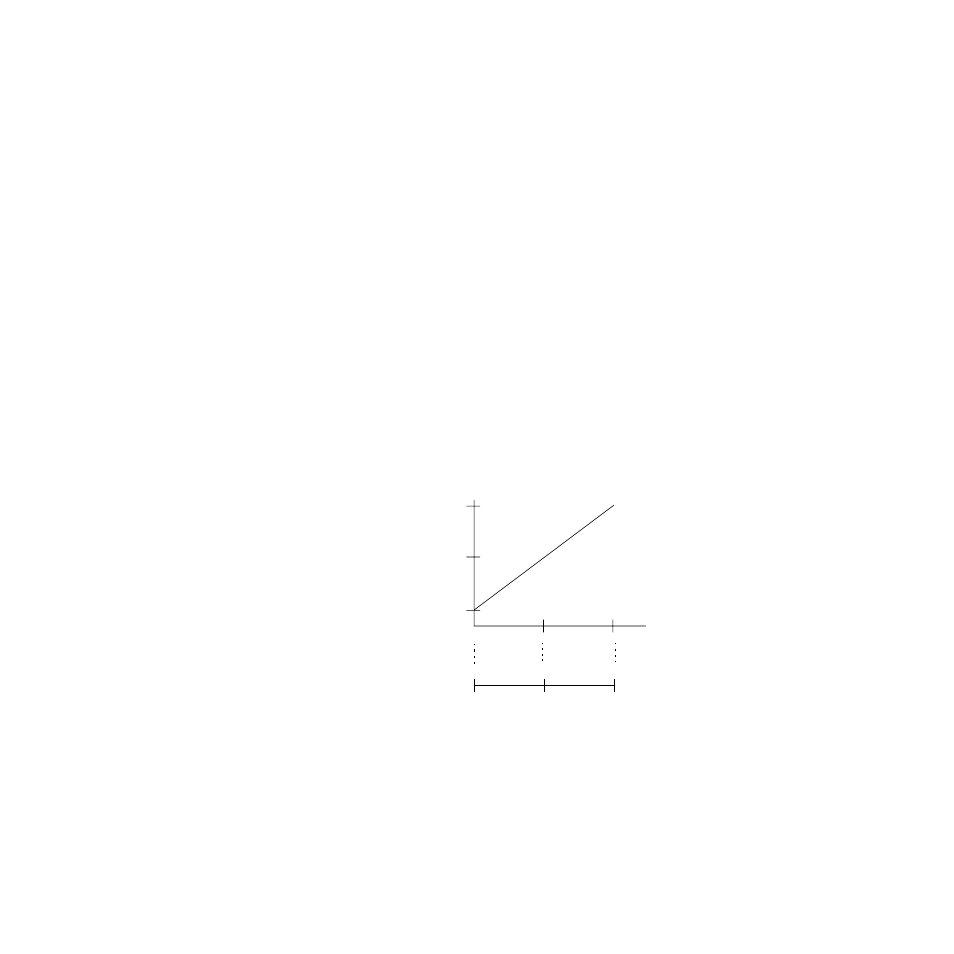

Figure 6.6 Secondary Loop Setpoint Related

to Primary Loop Output

As the temperature of loop 1 drops, the output of loop 1 goes

up proportionally and the setpoint of loop 2 goes up propor-

tionally. Thus heat is added to the system at the element

190°F

150°F

0%

50%

100%

Secondar

y Loop Setpoint

Process Variable 1

(SP1-PB1)

(SP1)

170°F

150°F

145°F

140°F

Heat Output (%)

(BASE SP + HT SPAN)

(BASE SP)

(eng. units)

SP: Setpoint

PB: Proportional Band

(eng.

units)

Primary Loop Output