Control ratio, Setpoint differential, Ratio control example: diluting koh – Watlow CLS200 User Manual

Page 142

Chapter 6: Enhanced Features

CLS200 Series User’s Guide

126

Watlow Anafaze

Doc.# 0600-3050-2000

for a higher setpoint. This value is expressed in the same

engineering units as the ratio loop’s process variable.

Selectable values: Any value from the minimum value of

the ratio loop’s process variable to its maximum value.

Control Ratio

Enter the multiplier to apply to the master loop’s process

variable.

Selectable values: 0.1 to 999.9.

Setpoint Differential

Enter the value to add or subtract from the ratio loop set-

point calculation before using it as the setpoint. This value

is expressed in the same engineering units as the ratio

loop’s process variable.

Selectable values: -9999 to 9999 with the decimal

placement determined by the DISP FORMAT setting for the

ratio loop.

Ratio Control Example: Diluting KOH

A chemical process requires a formula of two parts water

(H

2

O) to one part potassium hydroxide (KOH) to produce

diluted potassium hydroxide. The desired flow of H

2

O is 10

gallons per second (gps), so the KOH should flow at 5 gps.

Separate pipes for each chemical feed a common pipe. The

flow rate of each feeder pipe is measured by a CLS200, with

H

2

O flow as process variable 1 and KOH flow as process

variable 2. The outputs of loops 1 and 2 adjust motorized

valves.

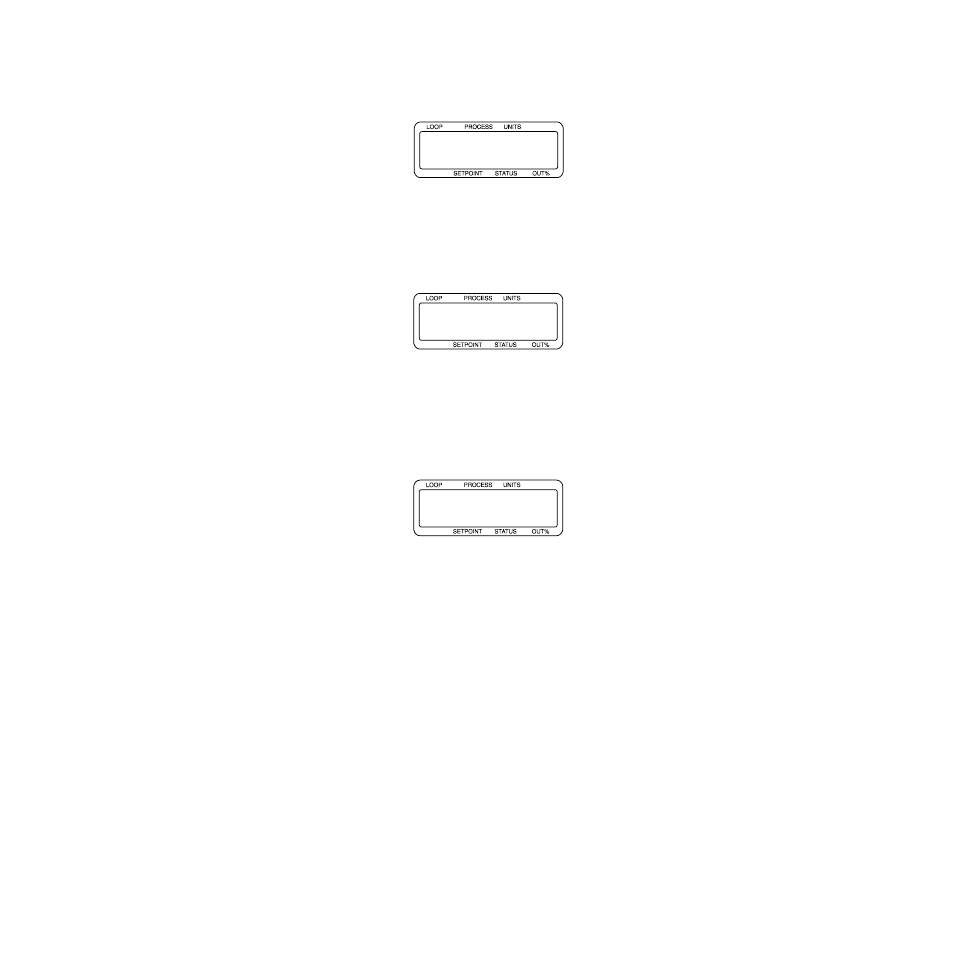

ALARM

02 RATIO CONTROL

MAX SP? 25

ALARM

02 RATIO CONTROL

CTRL RATIO? 1.0

ALARM

02 RATIO CONTROL

SP DIFF? 0