Reverse and direct action, Setting up and tuning pid loops, Proportional band (pb) settings – Watlow CLS200 User Manual

Page 175

CLS200 Series User’s Guide

Chapter 8: Tuning and Control

Doc.# 0600-3050-2000

Watlow Anafaze

159

Reverse and Direct Action

With reverse action an increase in the process variable

causes a decrease in the output. Conversely, with direct ac-

tion an increase in the process variable causes an increase

in the output. Heating applications normally use reverse

action and cooling applications usually use direct action.

Setting Up and Tuning PID Loops

After installing your control system, tune each control loop

and then set the loop to automatic control. When tuning a

loop, choose PID parameters that will best control the pro-

cess. This section gives PID values for a variety of heating

and cooling applications.

NOTE!

Tuning is a slow process. After adjusting a

loop, allow about 20 minutes for the change

to take effect.

Proportional Band (PB) Settings

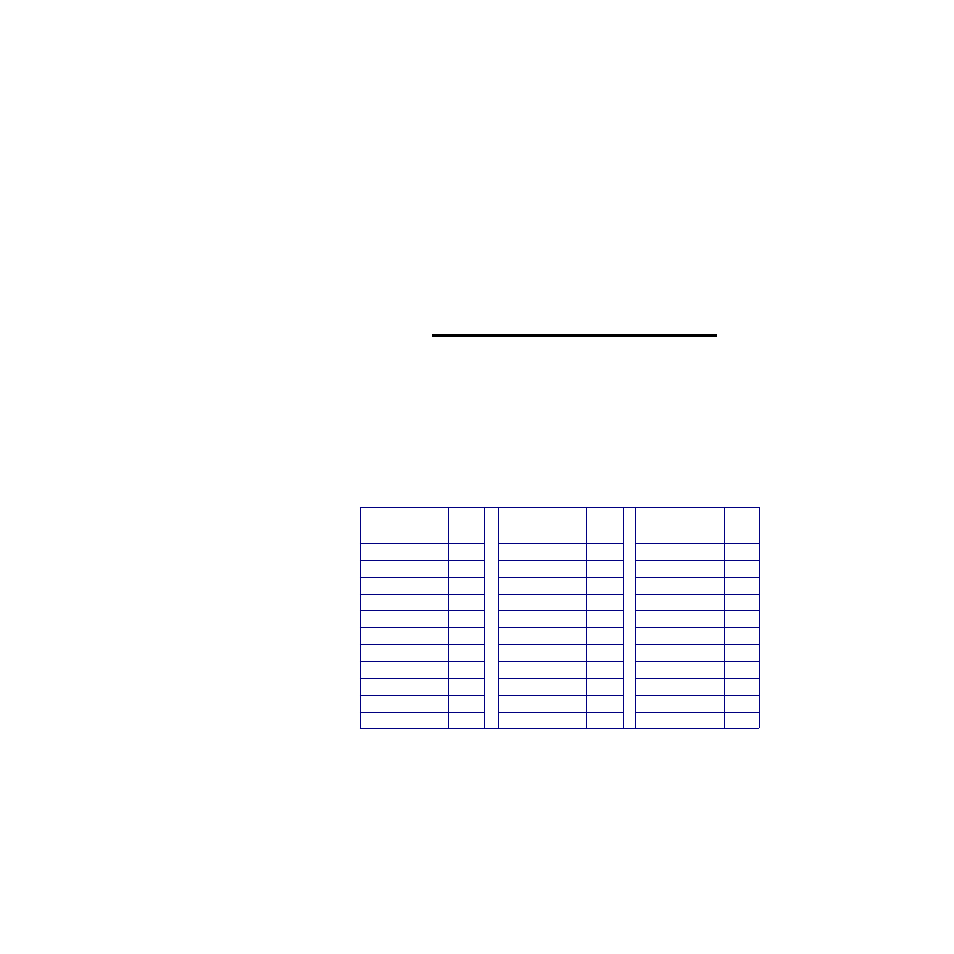

Table 8.1 shows proportional band settings for various

temperatures in degrees Fahrenheit or Celsius.

Table 8.1

Proportional Band Settings

As a general rule, set the proportional band to 10% of the

setpoint below 1000

˚

and 5% of the setpoint above 1000

˚

.

This setting is useful as a starting value.

Temperature

Setpoint

PB

Temperature

Setpoint

PB

Temperature

Setpoint

PB

-100 to 99

20

1100 to 1199

75

2200 to 2299

135

100 to 199

20

1200 to 1299

80

2300 to 2399

140

200 to 299

30

1300 to 1399

85

2400 to 2499

145

300 to 399

35

1400 to 1499

90

2500 to 2599

150

400 to 499

40

1500 to 1599

95

2600 to 2699

155

500 to 599

45

1600 to 1699

100

2700 to 2799

160

600 to 699

50

1700 to 1799

105

2800 to 2899

165

700 to 799

55

1800 to 1899

110

2900 to 2999

170

800 to 899

60

1900 to 1999

120

3000 to 3099

175

900 to 999

65

2000 to 2099

125

3100 to 3199

180

1000 to 1099

70

2100 to 2199

130

3200 to 3299

185