Watlow CLS200 User Manual

Page 148

Chapter 6: Enhanced Features

CLS200 Series User’s Guide

132

Watlow Anafaze

Doc.# 0600-3050-2000

Table 6.5

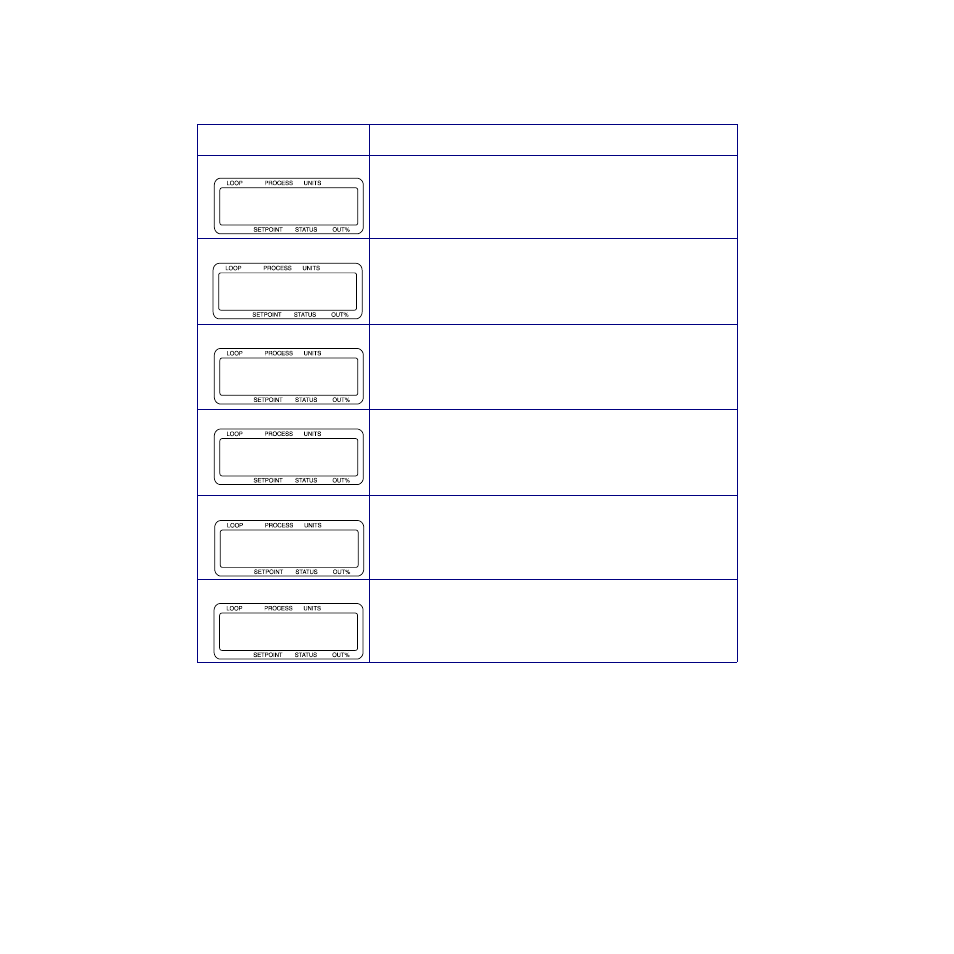

Application Example: Setting Up

Differential Control

3.

Press

BACK several times until the normal loop display

appears. The setpoint of loop 2 will now be equal to

process variable of loop 1 plus 50˚ F.

4.

To complete the differential control setup, loop 1 and

loop 2 must be configured for inputs, outputs, and

alarms. See Chapter 4, Setup for information on loop

setup.

Display

User Input

Press

YES to setup the ratio control parameters for loop 2.

Assign loop 01 to be the master loop. Press

ENTER.

Enter the minimum ratio loop setpoint. For this example, we will

use 300.0° F. Press

ENTER.

Enter the maximum ratio loop setpoint. For this example, we will

use 400.0° F. Press

ENTER.

Enter the control ratio, which is the multiple applied to the master

process variable. In this example the ratio is 1.0. Press

ENTER.

Enter the setpoint differential (or offset). For this example, we have

an offset of +50. Press

ENTER.

ALARM

SETUP LOOP 02

RATIO CONTROL?

ALARM

02 RATIO CONTROL

MSTR LOOP? 01

ALARM

02 RATIO CONTROL

MIN SP? 300.0

ALARM

02 RATIO CONTROL

MAX SP? 400.0

ALARM

02 RATIO CONTROL

CTRL RATIO? 1.0

ALARM

02 RATIO CONTROL

SP DIFF.? 50