Ratio control – Watlow CLS200 User Manual

Page 140

Chapter 6: Enhanced Features

CLS200 Series User’s Guide

124

Watlow Anafaze

Doc.# 0600-3050-2000

even though the temperature near the element may have

been at setpoint (150˚ F).

With proportional control, when loop 1 is at setpoint, its

output is 0%, and the setpoint of loop 2 is equal to the base

setpoint (150˚ F). If the temperature of loop 1 drops to 149˚

F, the deviation results in a proportional output of 10%.

This times the span of 40˚ F results in an increase in set-

point for loop 2 of 4˚ F. The loop 2 setpoint increases to 154˚

F. For every degree that loop 1 drops, loop 2 increases by 4˚

F until the output of loop 1 is 100% and the loop 2 setpoint

is 190˚ F. Any further drop in the loop 1 process variable

does not affect loop 2.

The PID parameters of loop 2 must be tuned to perform ef-

ficient control.

For two-zone cascade control systems, the PID settings for

both loops, the primary plus the secondary, must be opti-

mized for good temperature control.

See Chapter 4, Setup for information on tuning PID loops.

Ratio Control

Ratio control allows the process variable of one loop (mas-

ter loop), multiplied by a ratio, to be the setpoint of another

loop (ratio loop). You can assign any process variable to de-

termine the setpoint of a ratio loop.

By adjusting the ratio control parameters, you can adjust

the influence that the master loop process variable has on

the setpoint of the ratio loop.

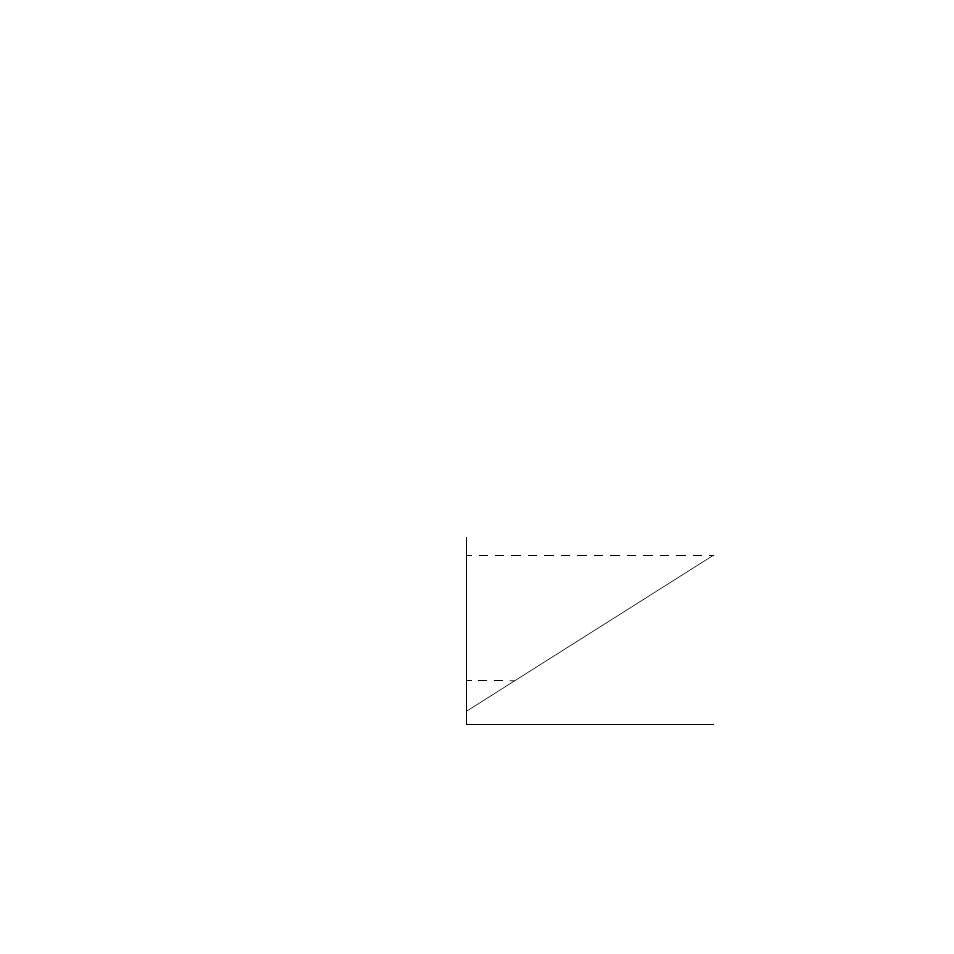

Figure 6.7 Relationship Between the Master

Loop’s Process Variable and the

Ratio Loop’s Setpoint

Maximum SP

Minimum SP

Minimum

Maximum

Master PV * Control Ratio + SP Diff

erential

Ratio Loop Setpoint

Master Loop Process Variable

SP Differential

SP: Setpoint

PV: Process Variable

PV

PV