Spread, Restore pid digital input – Watlow CLS200 User Manual

Page 108

Chapter 4: Setup

CLS200 Series User’s Guide

92

Watlow Anafaze

Doc.# 0600-3050-2000

larger value results in a slower, or more dampened, re-

sponse to changes in the process variable.

Selectable values: 0 to 255. 0 disables the output filter.

Spread

For a loop using on/off control, the spread is the control hys-

teresis. This determines the difference between the point at

which a heat output turns off as the temperature rises, and

the point at which it turns back on as the temperature falls.

For a loop using PID control, the spread determines how

far the process variable must be from the setpoint before

the controller can switch from heating to cooling. A loop

will not switch from heat to cool or vice versa unless the

process variable deviates from setpoint by more than the

spread.

When the loop is using PID control and the spread is set to

0, the PID calculation alone determines when the heat or

cool output should be on.

Selectable values: 0 to 255, 25.5, 2.55, .255, or.0255,

depending upon the DISP FORMAT setting.

Restore PID Digital Input

To enable the sensor failure recovery feature, select a digi-

tal input at this parameter. If the specified input is held

low when the sensor fails, the loop returns to automatic

control after a failed sensor is corrected.

Selectable range: NONE (disable the sensor failure recov-

ery feature), 1 to 8.

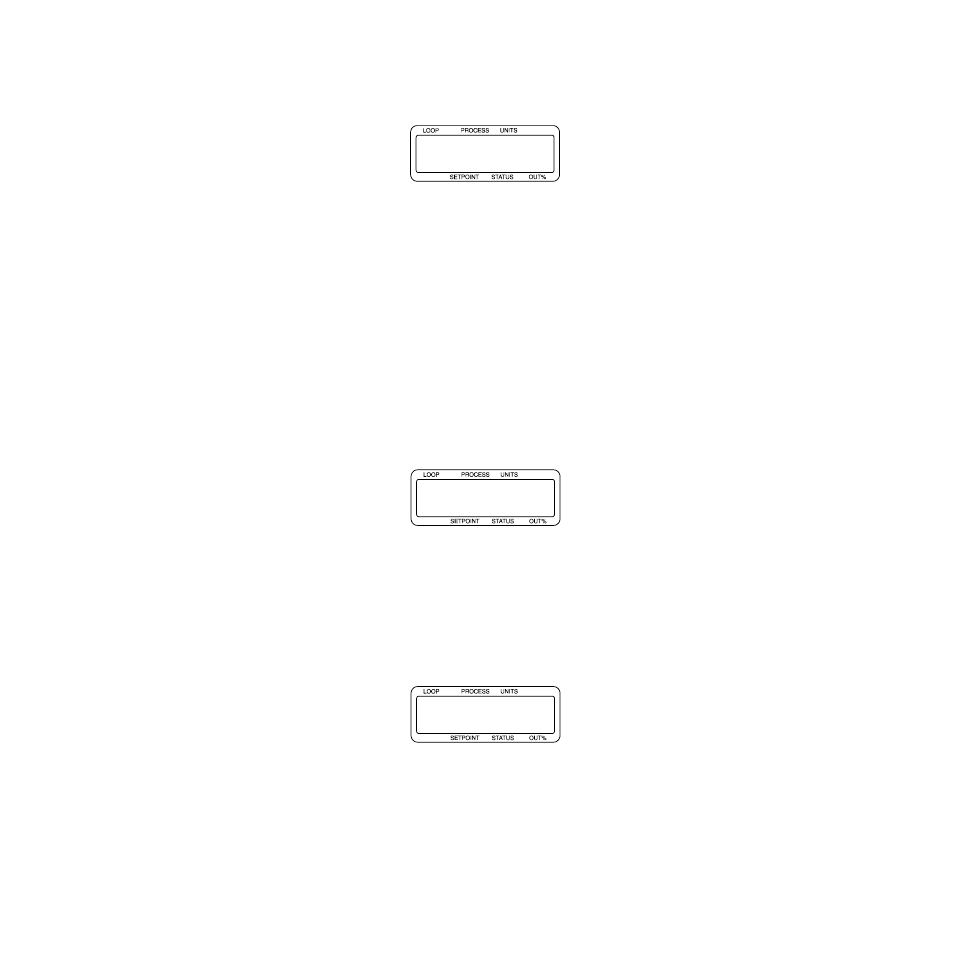

ALARM

01 HEAT CONTROL

FILTER ? 3

ALARM

01 SPREAD ?

5

ALARM

01 RESTORE PID

DIGIN ? NONE