Battery voltage loss detection, Battery voltage loss detection -18 – Rockwell Automation 2092-DAx Ultra1500 User Manual User Manual

Page 98

Publication 2092-UM001D-EN-P — July 2005

5-18

Ultra1500 Application Examples

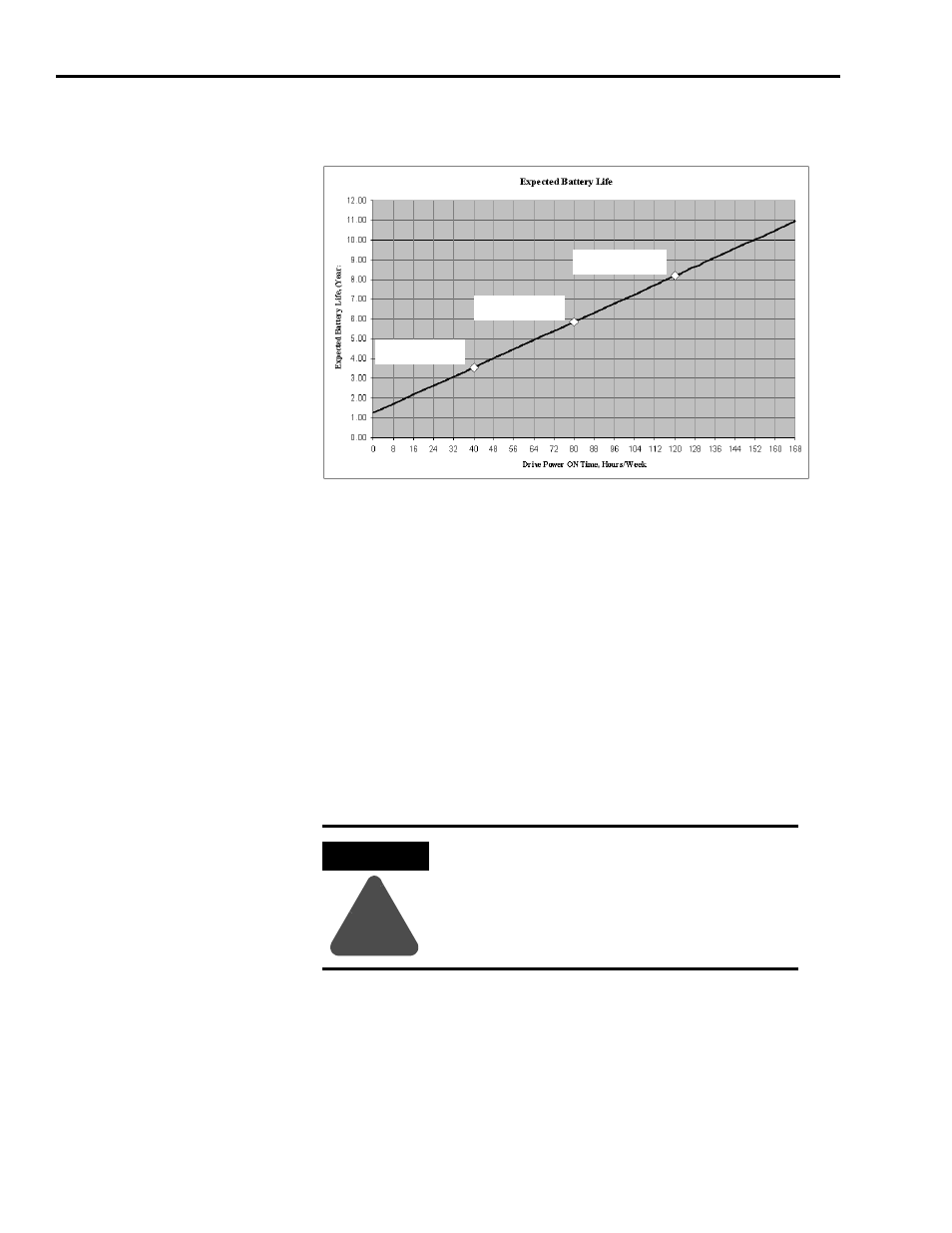

Figure 5.5

Ultra1500 Expected Battery Life

In Figure 5.5, three data points are highlighted. For example, if the control

power of the drive is applied for 40 hours per week, (and the encoder uses

battery power the remaining 128 hours in the week), the expected battery life is

about 3.5 years. In applications where machine downtime is a concern,

replacing the battery once a year or once every two years may be a prudent

measure to avoid any interruption.

Battery Voltage Loss Detection

The encoder in the TL-Series motors monitors the battery voltage at all times,

and supplies the Ultra1500 drive with battery status that is in turn relayed to

the user through the status display of the drive.

If the battery voltage is above 3.1 Volts, the encoder will be satisfied with the

battery voltage and no warnings or errors are reported.

ATTENTION

!

The upper controller is responsible for managing the

system behavior in the event of a loss of absolute

position, which may require re-homing of the

machinery to avoid incorrect motion.

Drive operated for

one shift a week.

Drive operated for

two shifts a week.

Drive operated for

three shifts a week.