Absolute positioning, Encoder battery installation, Absolute positioning -16 – Rockwell Automation 2092-DAx Ultra1500 User Manual User Manual

Page 96: Encoder battery installation -16, Absolute positioning on, 16 fo

Publication 2092-UM001D-EN-P — July 2005

5-16

Ultra1500 Application Examples

Absolute Positioning

The Ultra1500 can be used with the TL-Series motors, which have serial

encoders with battery-backed, multi-turn absolute position capability. The

absolute position of the motor is read from the encoder by the drive, and the

drive in turn provides the absolute position to the external controller.

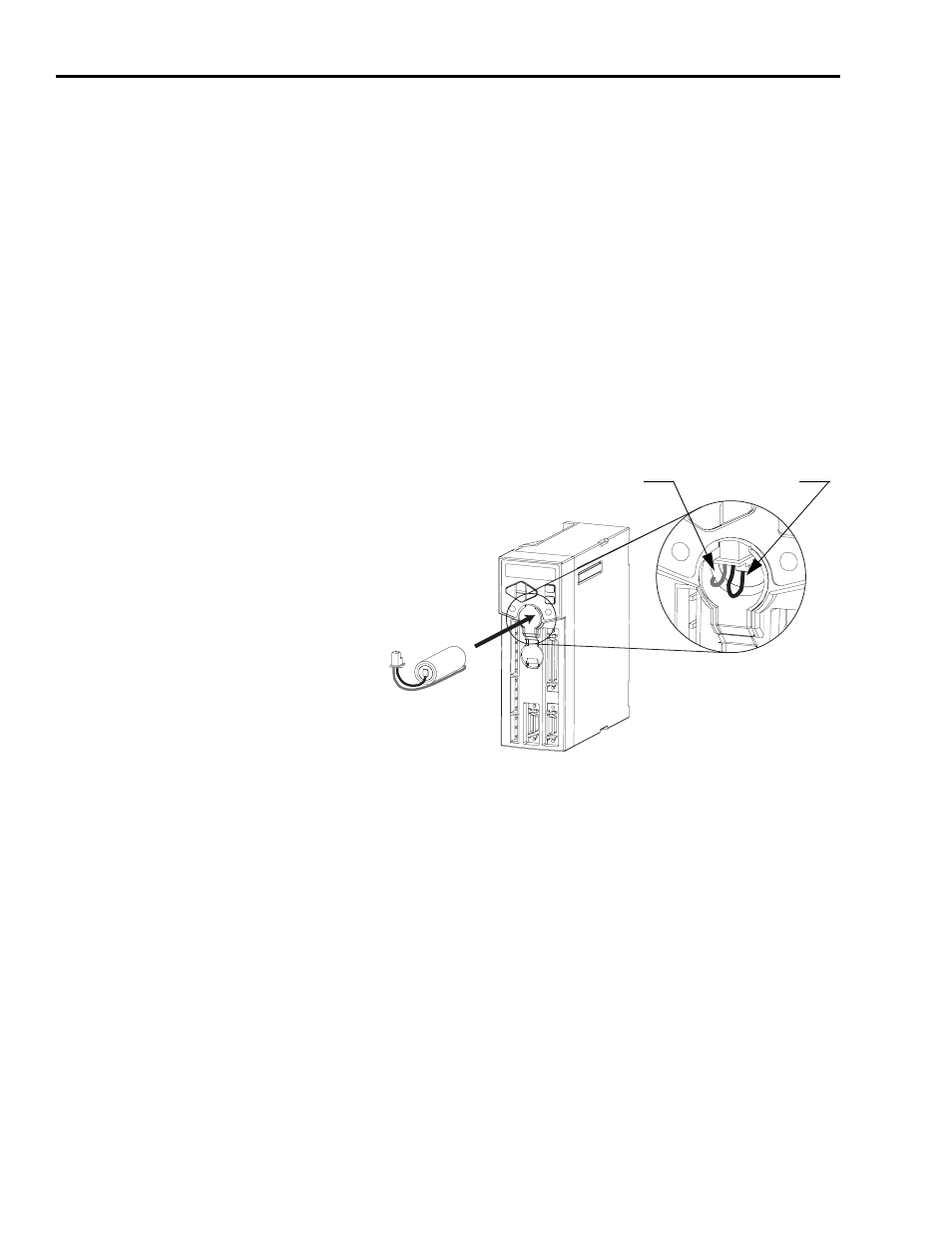

Encoder Battery Installation

In order to make use of the multi-turn absolute capability of the TL-Series

motors, a 3.6V battery must be connected to the motor. The Ultra1500

provides two methods to connect a battery. The easiest method is to install a

½-size AA lithium battery, as shown in Figure 5.4, in the battery compartment

of the Ultra1500.

Figure 5.4

Ultra1500 Battery Installation.

To install a new battery, or replace an existing battery; perform the following

steps:

1. For a new installation or if a battery low voltage fault has occurred,

remove main and control AC power from the drive. Otherwise, if this is a

maintenance update or if a battery low voltage warning has occurred,

remove only the main AC power but retain the control AC power so that

the absolute position of the motor is not lost when the existing battery is

disconnected.

2. Open the BATT compartment door. See Figure 5.4 for location. If the

battery needs to be removed, disconnect battery by carefully pulling

downward on the connector. Slightly raise the BATT door for clearance,

and slide battery out of the drive. Note: Pressure is best applied to both

sides of the connector. A needle nose pliers or similar tool can be used to

apply pressure.

Battery connector is keyed:

Flat surface faces front of drive,

Rounded surfaces face inward.

Positive wire (red) on

left-side of connector.

Negative wire (black) on

right-side of connector.

When disconnecting the battery, pressure

is best applied to both sides of the

connector.

A needle nose plier or similar tool can be

used to apply pressure.

Battery connector installed on

Ultra1500 drive