Rockwell Automation 2092-DAx Ultra1500 User Manual User Manual

Page 132

Publication 2092-UM001D-EN-P — July 2005

6-6

Maintaining and Troubleshooting Your Ultra1500

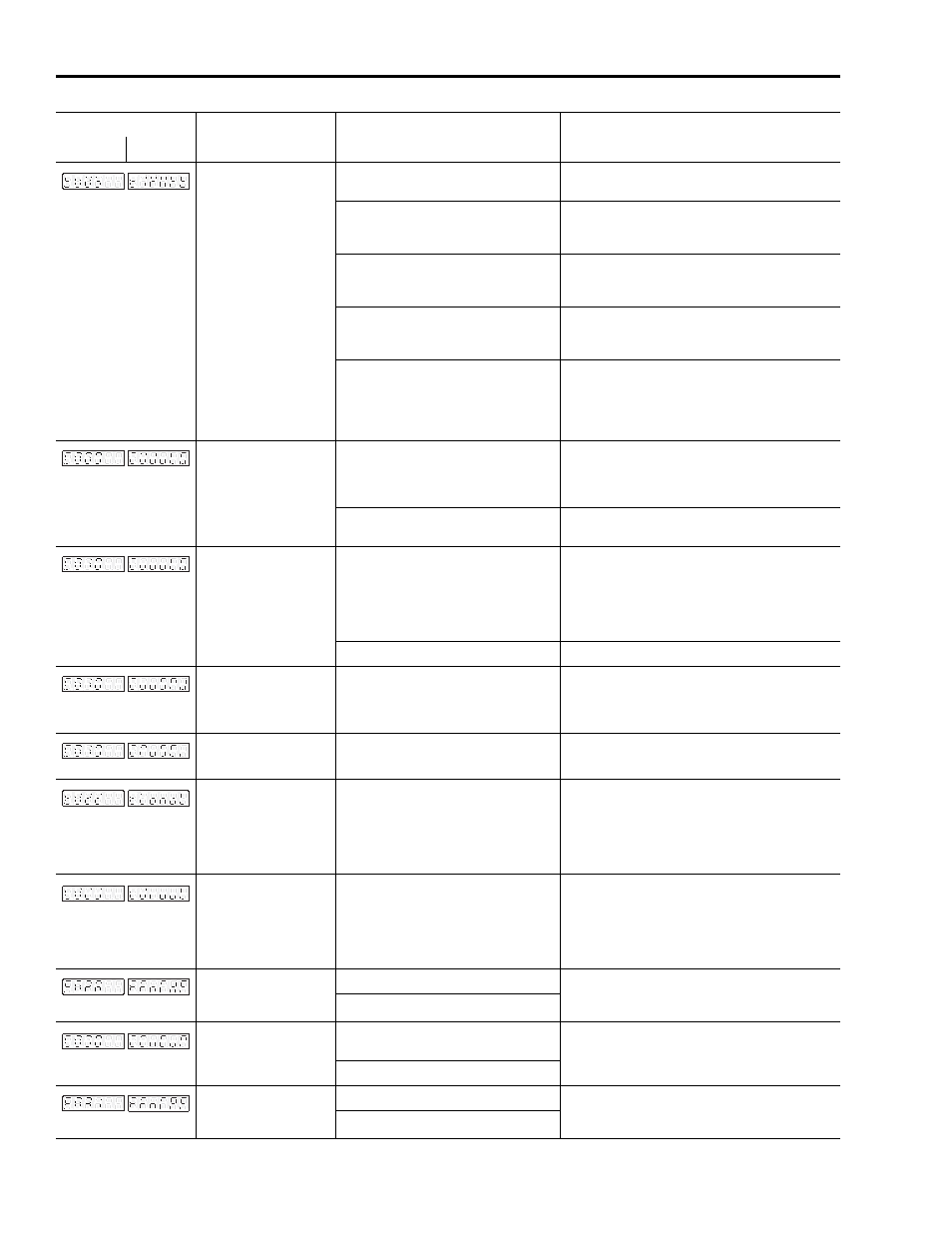

E005

IPM Error

Motor cables shorted

Verify continuity of motor power cable and

connector.

Motor winding shorted internally

Disconnect motor power cables from the motor. If

the motor is difficult to turn by hand, it may need to

be replaced.

Drive temperature too high

• Check for clogged vents or defective fan.

• Ensure cooling is not restricted by insufficient

space around the drive.

Operation above continuous power rating

• Verify ambient temperature is not too high.

• Operate within the continuous power rating.

• Reduce acceleration rates.

Drive has a bad IPM output, short circuit,

or overcurrent

Remove all power and motors connections, then

perform a continuity check from the DC bus to the U,

V, and W motor terminals. If continuity exists, check

for wire fibers between terminals, or send drive in for

repair.

E009

Bus Undervoltage

Low AC line/AC power input

• Verify voltage level of the incoming AC power.

• Check AC power sources for glitches or line drop.

• Install uninterruptible power supply (UPS) on the

AC input.

Attempted to enable drive without main

power active.

Apply main power before enabling drive.

E010

Bus Overvoltage

Excessive regeneration of power (i.e.,

When the motor is driven by an external

mechanical force, it may regenerate too

much peak energy through the drive’s

power supply and the drive faults to save

itself from an overload.)

• Verify shunt circuit.

• Adjust motion profile to stay within the range of

the regenerative resistor.

• Replace regenerative transistor.

• Replace drive.

Excessive AC input voltage

Verify input is within specification.

E018

Motor Overspeed

Motor speed exceeds maximum

• Confirm encoder wiring.

• Retune drive system.

• Verify input gain of external speed or torque

command.

E019

Excess Position Error

Position error exceeds permitted value

• Increase following error limit.

• Check position loop tuning.

E022

Motor Continuous

Current Overload

The internal filter protecting the motor

from overheating has tripped

• Reduce acceleration rates.

• Reduce duty cycle (ON/OFF) of commanded

motion.

• Increase time permitted for motion.

• Use larger drive and motor.

• Checking tuning.

E023

Drive Overload

The motion application requires average

drive current in excess of rated capability

• Reduce acceleration rates.

• Reduce duty cycle (ON/OFF) of commanded

motion.

• Increase time permitted for motion.

• Use larger drive and motor.

• Check tuning.

E028

Encoder Data Range

Error

Encoder not programmed correctly

Replace motor.

Encoder memory corrupted

E030

Encoder Cable Open

Communication not established with an

intelligent encoder.

• Verify motor selection.

• Verify the motor supports automatic identification.

• Verify encoder wiring.

Hall error

E031

Encoder Data Parameter

Error

Encoder not programmed correctly

Replace motor.

Encoder memory corrupted

Error Display

Description

Possible Cause(s)

Action/Solution

Code

Text