End of appendix – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 922

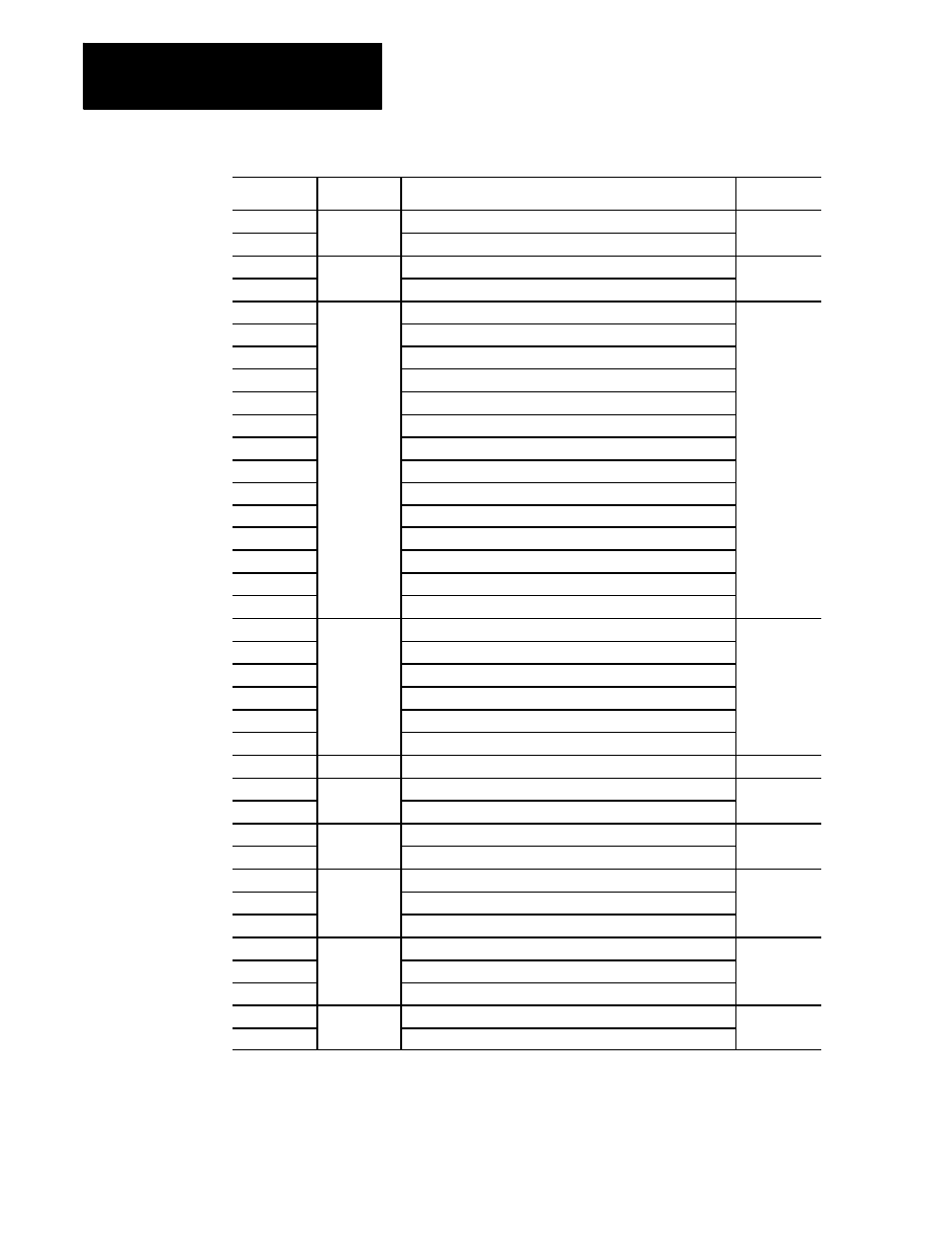

G-code Tables

Appendix C

C-4

A

Type

Function

Modal Group

G66.1

Paramacro Modal Call

G67

Paramacro Modal Call (Cancel)

G68

16

Part Rotation

Modal

G69

Part Rotation (Cancel)

G73

09

Deep Hole Peck Drilling Cycle (With dwell)

Modal

G74

Left-Hand Tapping Cycle

G74.1

Left-Hand Solid Tapping Cycle

G76

Boring Cycle (Spindle Shift)

G80

Cancel or End Fixed Cycle

G81

09

Drilling Cycle (No Dwell, Rapid Out)

Modal

G82

Drilling Cycle (Dwell, Rapid Out)

G83

Deep Hole Peck Drilling Cycle

G84

Right-Hand Tapping Cycle

G84.1

Right-Hand Solid Tapping Cycle

G85

Boring Cycle (No Dwell, Feed Out)

G86

Boring Cycle (Spindle Stop, Rapid Out)

G87

Back Boring Cycle

G88

Boring Cycle (Spindle Stop, Manual Out)

G88.1

00

Pocket Milling Roughing Cycle

Non--Modal

G88.2

Pocket Milling Finishing Cycle

G88.3

Post Milling Roughing Cycle

G88.4

Post Milling Finishing Cycle

G88.5

Hemispherical Milling (Roughing Cycle)

G88.6

Hemispherical Milling (Finishing Cycle)

G89

09

Boring Cycle (With Dwell, Feed Out)

Modal

G89.1

00

Irregular Pocket Milling (Roughing Cycle)

Non--Modal

G89.2

Irregular Pocket Milling (Finishing Cycle)

G90

03

Absolute Mode

Modal

G91

Incremental Mode

G92

00

Coordinate System Offset (Using Tool Positions)

Non-Modal

G92.1

Coordinate System Offset (Cancel)

G92.2

Selected Coordinate System Offsets (Cancel)

G93

05

Inverse Time Feed Mode

Modal

G94

Feed-per-minute mode

G95

Feed-per-revolution Mode

G98

10

Initial Level Return in Milling Cycles

Modal

G99

R-Point Level Return in Milling Cycles

END OF APPENDIX