5 mdi or manual motion during cutter compensation – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 564

Cutter Diameter Compensation

(G40, G41, G42)

Chapter 21

21-46

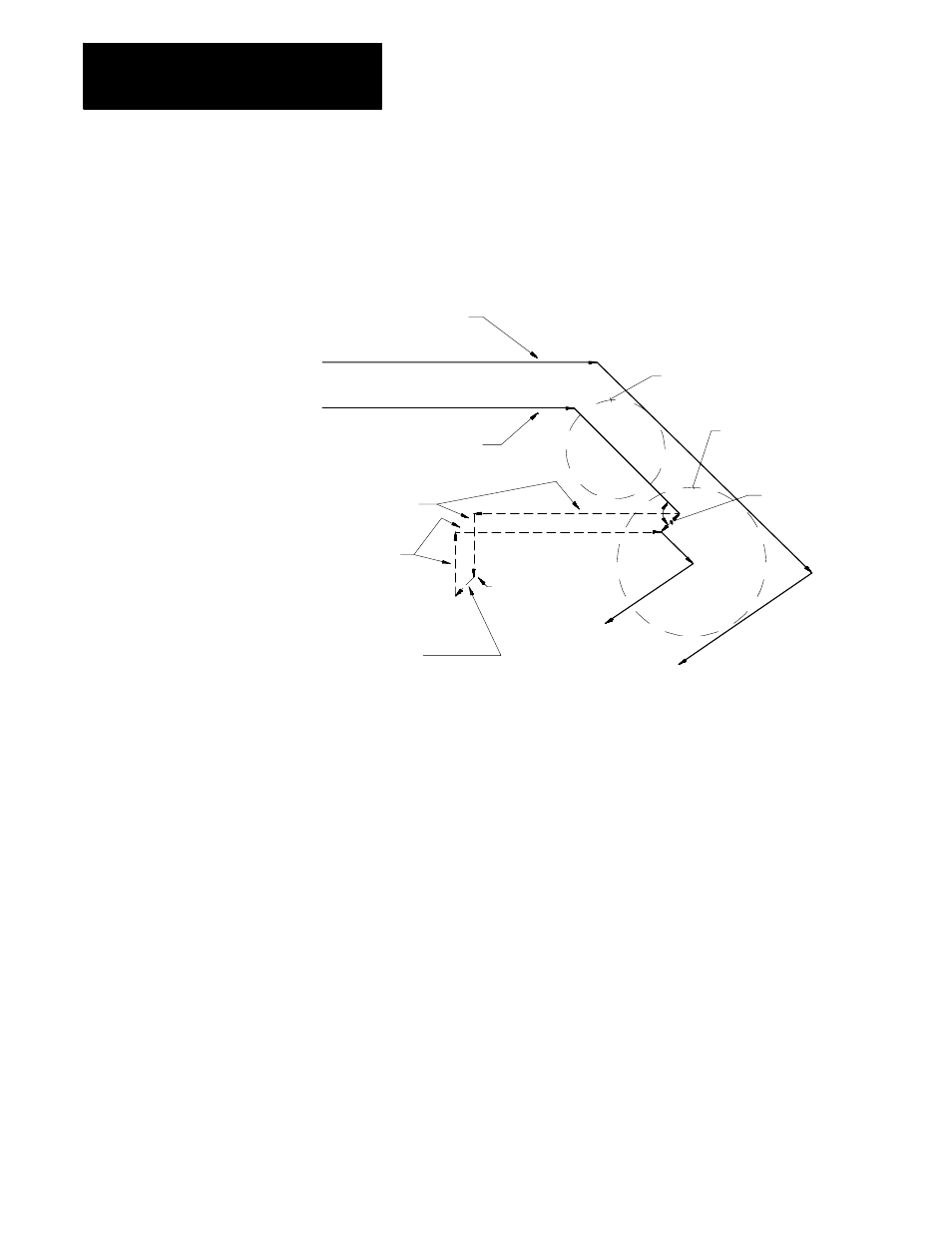

Figure 21.43 gives an example of a typical change in tool radius during jog

retract with cutter compensation active.

Figure 21.43

Change in Cutter Radius During a Jog Retract

Original tool

radius

New

tool

radius

Difference in

tool radius

•

R

Programmed path

Compensated path

Jog retract moves

Jog retract

return moves

Tool radius

changed here

90

•

Generated offset block

from difference in

tool radius

•

R

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

If exiting automatic mode and either a MDI motion block is executed or a

manual jog motion is made, the cutter compensation feature, if active,

re-initializes when the next motion block is executed in automatic mode.

The compensation feature compensates the cutting tool one tool radius

perpendicular to the tool path of the next motion block that is executed in

automatic mode. In effect, the control generates its own entry move for

compensation with the first compensated block being the next block

executed in automatic operation.

Important: The cutter compensation feature is not available for any

motion blocks that are programmed in MDI mode. The cutter

compensation mode may be altered by programming either G41, G42, or

G40; or the tool radius may be changed in an MDI program. However,

none of the tool paths executed in MDI are compensated. No changes

made to cutter compensation are applied until the next block executed in

automatic mode.

21.6.5

MDI or Manual Motion

During Cutter Compensation