Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 681

Skip, Gauge, and Probing Cycles

Chapter 27

27-7

Tool Gauging Application Example

A typical application for these G-codes in determining tool offsets would

execute as follows:

1.

When the control executes the G37 block, the triggering device

moves towards the tool using the axis specified in the block.

2.

When the control receives the appropriate skip signal through PAL,

axis motion stops.

3.

The control records the position when the skip signal is received. It

determines the difference by subtracting the position specified with

the axis word in the G37 block from this position. The difference is

then added to, or replaces the value in the appropriate geometry or

wear table for the currently active tool offset number.

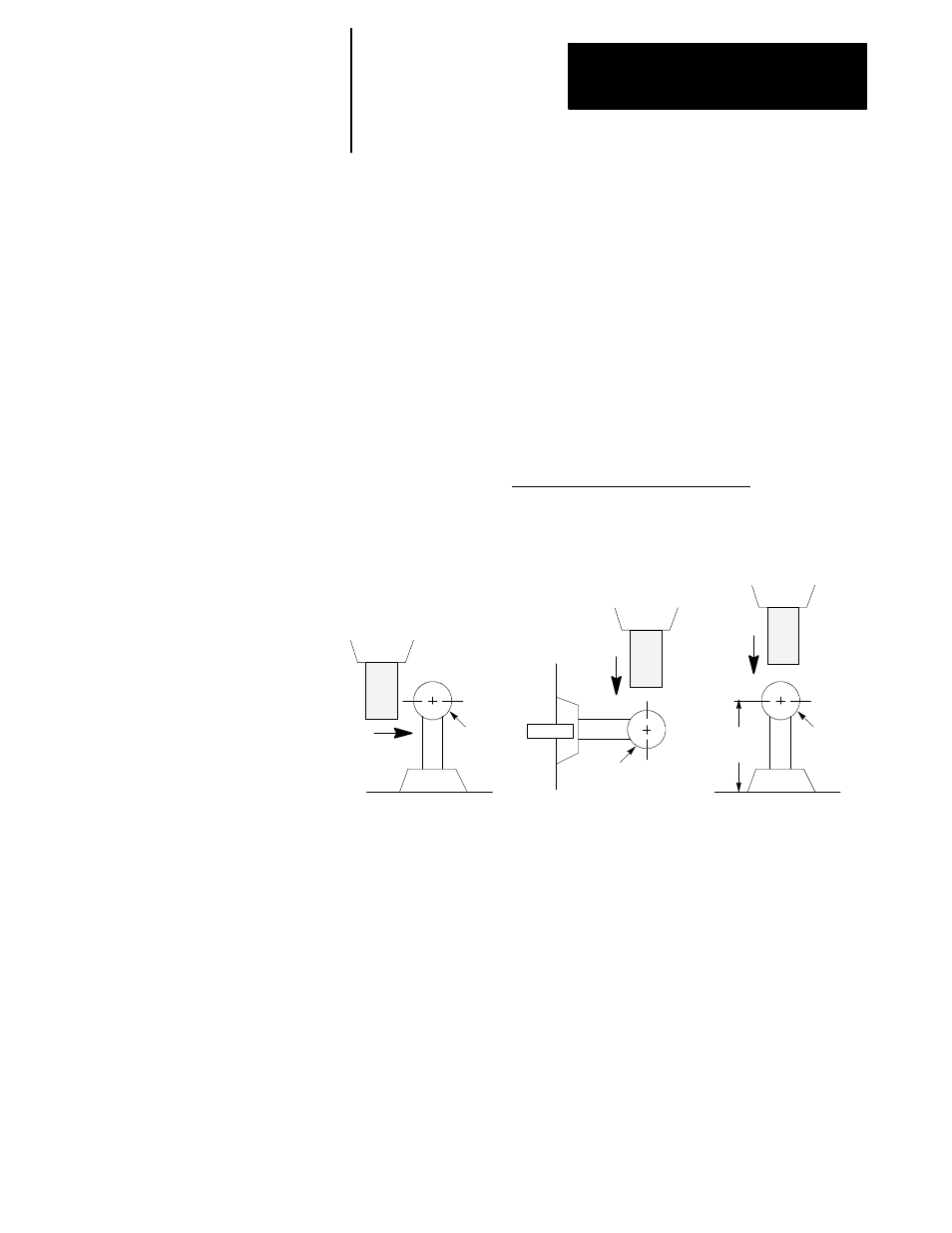

Figure 27.1

Typical Tool Gauging Configurations

Probe

Probe

radius

Tool

Probe

Probe

radius

Tool

Probe

Probe

radius

Probe

length

Tool

Case 1

Case 2

Case 3

Figure 27.1 illustrates 3 typical tool gauging configurations. All 3 cases

assume that the probe is at a known, fixed point on the machine.

Note that in Case 1 the tool radius is being gauged, while in Case 2 the tool

length is being gauged. In both of these cases, only the probe tip radius is

significant to the control in calculating the offset adjustment.

In Case 3, the tool length is being gauged, and both the probe radius and

the probe length are significant to the control’s offset adjustment

calculations.

Important: The tool gauging configuration Case 3 depicted in Figure 27.1

is not recommended due to the risk of probe damage.