1 mdi basic operation – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 112

Manual/MDI Operation Modes

Chapter 4

4-12

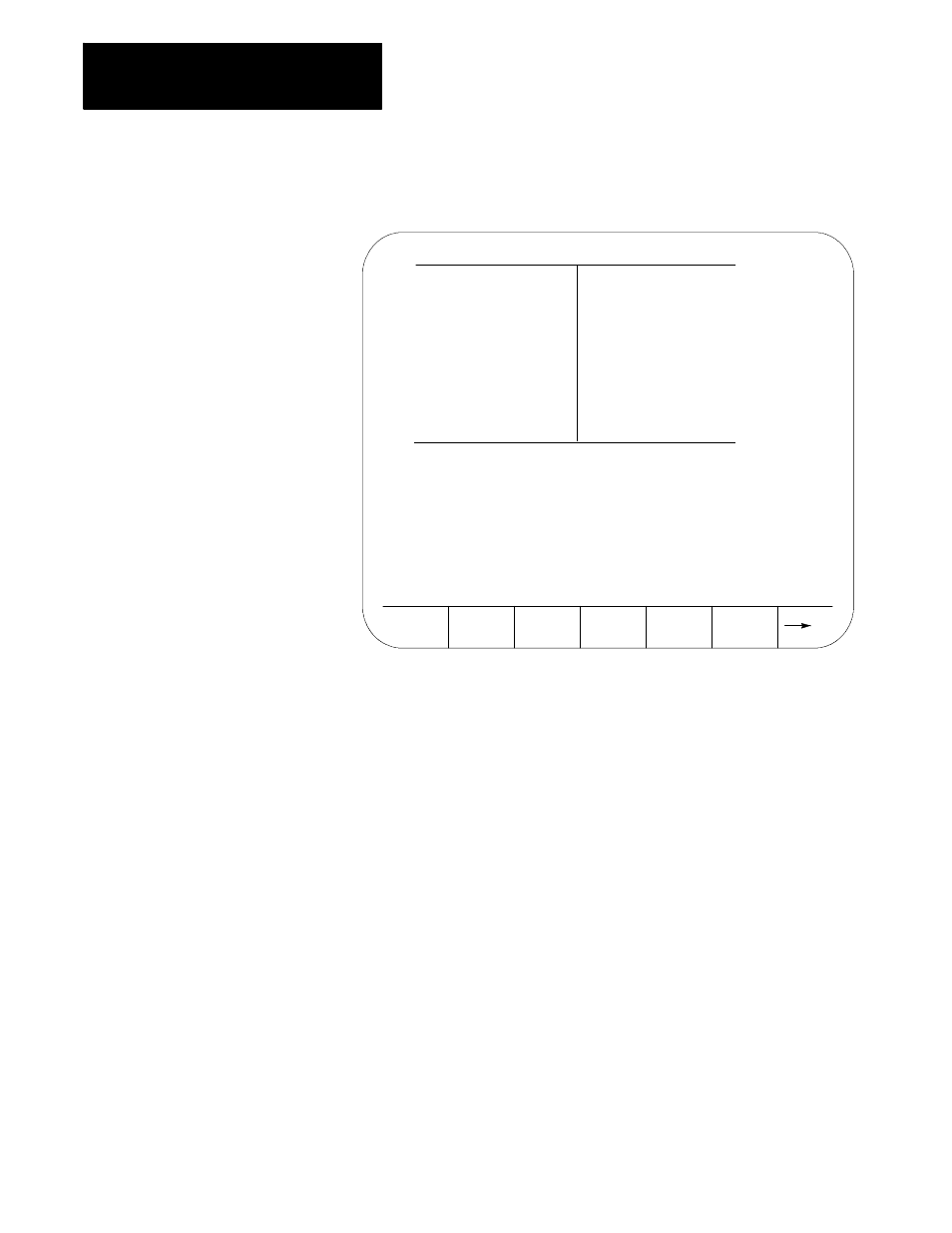

Figure 4.5

Program Display Screen in MDI Mode

PRGRAM

MANAGE

OFFSET MACRO

PARAM

PRGRAM

CHECK

SYSTEM

SUPORT

E-STOP

PROGRAM[ MM

]

F

00000.000 MMPM

X

00000.000

S

0

Z

00000.000

T

1

U

00000.000

W

00000.000

MEMORY 30000 MDI

STOP

N 99999

(First 4 blocks

of MDI shown here)

(PAL messages)

Operating procedures in the MDI mode include:

1.

When it is in MDI mode, the control accepts standard programming

blocks.

2.

Key in programming blocks (refer chapter 10). Each block, up to a

maximum of 62 characters, is separated with an end of block

statement. The blocks entered appear in the input area of the screen

(lines 2 and 3). The complete MDI program should be entered on

these lines since once you send the blocks to control memory, they

cannot be edited or added to.

The input cursor is the cursor shown on the input lines (lines 2 and 3

on the screen). To move the cursor right and left in the input area,

press and hold the

[SHIFT]

key while pressing the left and right

cursor keys. A new character will be inserted to the left of the cursor

automatically when you press any character key.

If you make a mistake keying in a character before it is sent, that

character can be edited by using the input cursor described on page

2-41.

4.5.1

MDI Basic Operation