1 altering work coordinate systems (g10l2) – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 323

Coordinate System Offsets

Chapter 11

11-7

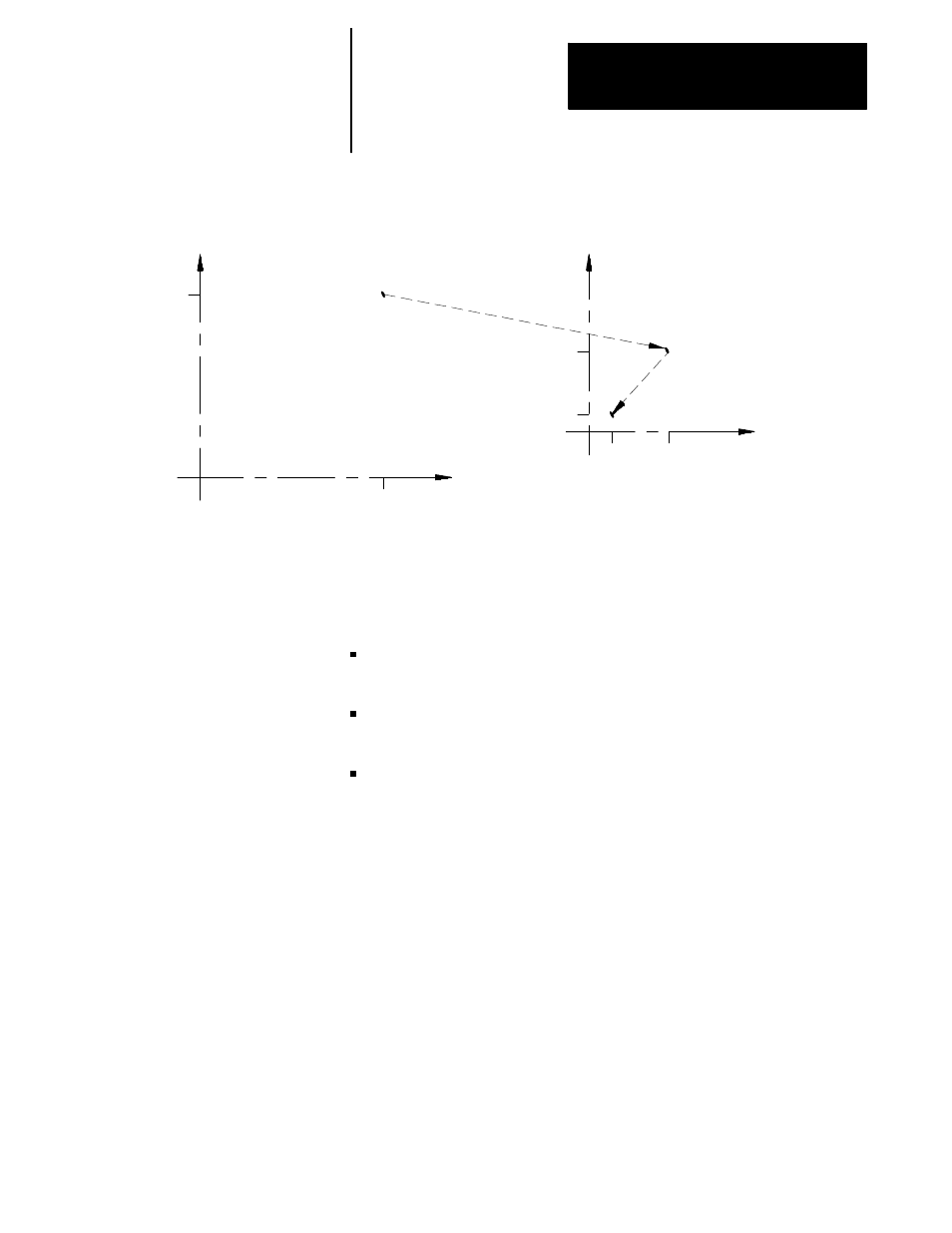

Figure 11.6

Results of Example 11.2

20

20

G54 Work Coordinate System

G55 Work Coordinate System

Y

X

Y

X

3

10

10

2

There are 4 methods to change the value of a work coordinate system zero

point in the work coordinate system table. Three methods can be found in

the following sections:

Manually alter the work coordinate system table as

described in section

3.3.

Alter the paramacro system parameter values 5221- 5386 as discussed in

chapter 28.

Alter through some external means defined by the system installers PAL

program (refer to your PAL reference manual).

The fourth method, and the one discussed in this section, alters the work

coordinate system table through G10 programming. Changing the values

in the table using any of these methods does not cause axis motion;

however, it does immediately shift the active coordinate system by the

amount entered. The format for altering the work coordinate systems

using G10 is as follows:

G10L2P__X__Y__Z__;

Important: The order of the words in this program block is important.

The L and P words must be programmed before any axis words are

programmed in the G10 block. Failing to follow this order can result in

data being misinterpreted and loaded into the table incorrectly.

11.2.1

Altering Work Coordinate

Systems (G10L2)