2 program configuration – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 280

Introduction to Programming

Chapter 10

10-6

Each machining operation performed by the control is determined by the

control’s interpretation of a group of words (commands) called a “block.”

Individual blocks in a part program define each machining process. Part

programs consist of a number of blocks that together define a complete

operation on a part.

Part program blocks are made up of:

characters ---- A character is a number, a letter, or a symbol that has a

specific meaning for the control. For example, 1, G, ; are characters

the control recognizes as meaningful information

addresses ---- An address is a letter that defines the instruction for the

control. Examples of addresses are: G, X, Z, F

words ---- A word consists of an address followed by a numeric value.

Examples of words are: G01, X10.5, F50., M2. Each word requires a

specific format for its numeric part. These formats are given in section

10.5

codes ---- There are industry standards for many of the G and M--codes

used here.

parameters ---- The control has a number of fixed cycles that are

initiated by a specific G--code. Other words appearing in those G--code

blocks are referred to as “parameters”, because their values are relevant

only to that G--code. For example, a Z--word generally refers to a Z axis

move, but when it appears in a block with a G83 peck drilling cycle, its

value refers to the depth of the hole to be drilled. In that case, it is a

“parameter” of the G83 fixed cycle

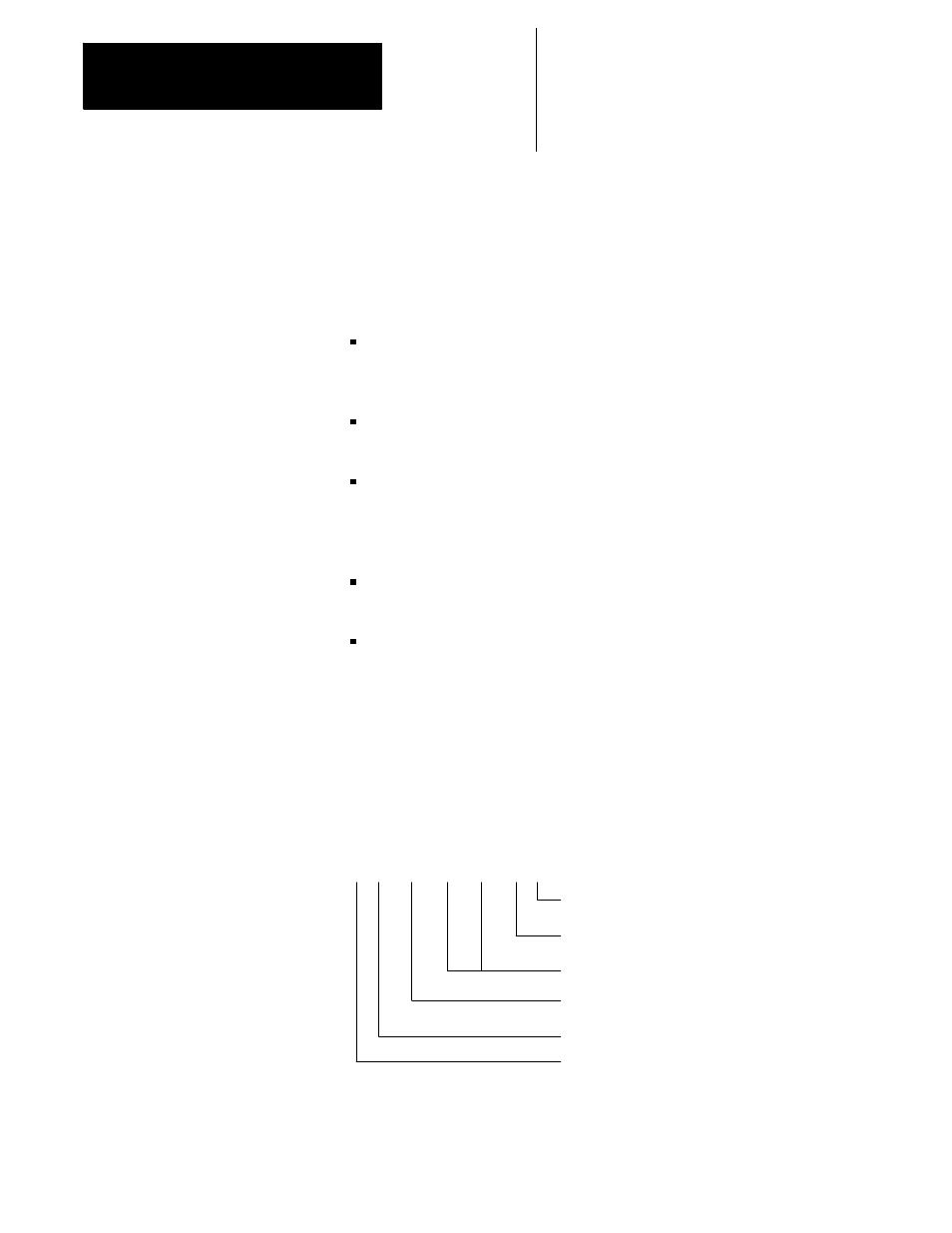

A block is a set of words and characters that define the operations of the

control. For example:

/ N3

G00

X10. Z10. M3 ;

end of block character

miscellaneous function word

(spindle on forward)

axis movement words

preparatory function word

(rapid positioning mode)

sequence number word

optional block delete character

10.2

Program Configuration