Template 11: boring cycle, spindle shift, Chapter 31 – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 843

Using Transfer Line Cycles

Chapter 31

31-41

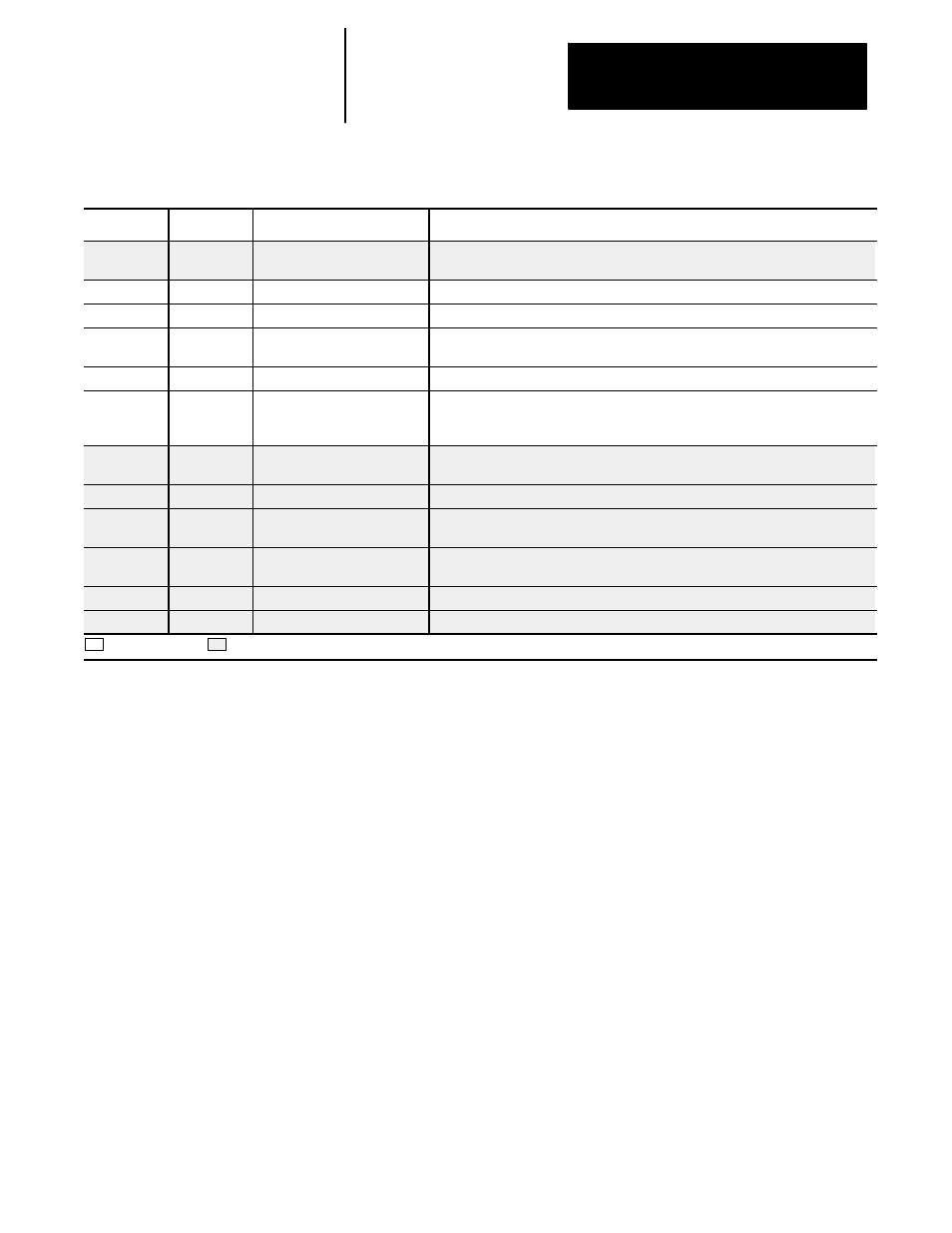

Template 11: Boring Cycle, Spindle Shift

Letter

Paramacro

Label

Description

G

500

G90/91

G-codes G90 or G91 for absolute or incremental modes. At this time only absolute

mode, G90, is available.

X,Y

501, 502

HOLE POSITION X, Y

The location to which the tool moves before it begins a boring operation.

X

503

DEPTH TO TAP OR HOLE

The location to which the tool bores into the part.

R

504

CLEAR POSITION

The location that the tool retracts to after an operation. It is completely free of the

part. This also known as the R plane.

X,Y

505, 506

RETURN POSITION X, Y

The location where the controls starts and stops a cycle.

F

507

FEEDRATE

The feedrate for drilling/boring operations, and all moves represented by the solid

lines in the QuickView screens. This is also the maximum feedrate for operations

that use adaptive depth.

Q

508

SHIFT AMOUNT

The amount of distance the spindle shifts so that the tool can retract without

damaging the part. The orient of the part when it completes the cut is set in AMP.

X

509

TOOL CHANGE POSITION

The location the control moves to so that a tool change may be performed.

I

510

HARD STOP SENSE ZONE

Once it reaches this location, the control knows to expect a hard stop before

reaching the hole bottom.

I

511

ADAPTIVE DEPTH

INCREMENT

The amount of distance that the control will increment the tool into the part during an

adaptive depth operation.

M

512

M03/M04

The M--code used to turn the spindle clockwise or counter-clockwise.

S

513

SPINDLE SPEED

The speed of the spindle. Measured in revolutions per minute.

Required entry

Optional entry