Spindles – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 437

Chapter

17

17-1

Spindles

This chapter describes how to program spindles:

Information about:

On page:

Controlling Spindle

17-1

Spindle Orientation

17-3

Spindle Direction

17-5

Synchronized Spindles

17-6

The G12 code is used to program the active controlling spindle for features

and modes requiring spindle operation. The G12 code is modal. Only one

spindle may be the controlling spindle. Only the 9/260-9/290 control uses

more than one spindle. All other spindles are auxiliary spindles.

G12.1 — Spindle 1 Controlling

G12.2 — Spindle 2 Controlling

G12.3 — Spindle 3 Controlling

Table 17.A shows the spindle capabilities of each control.

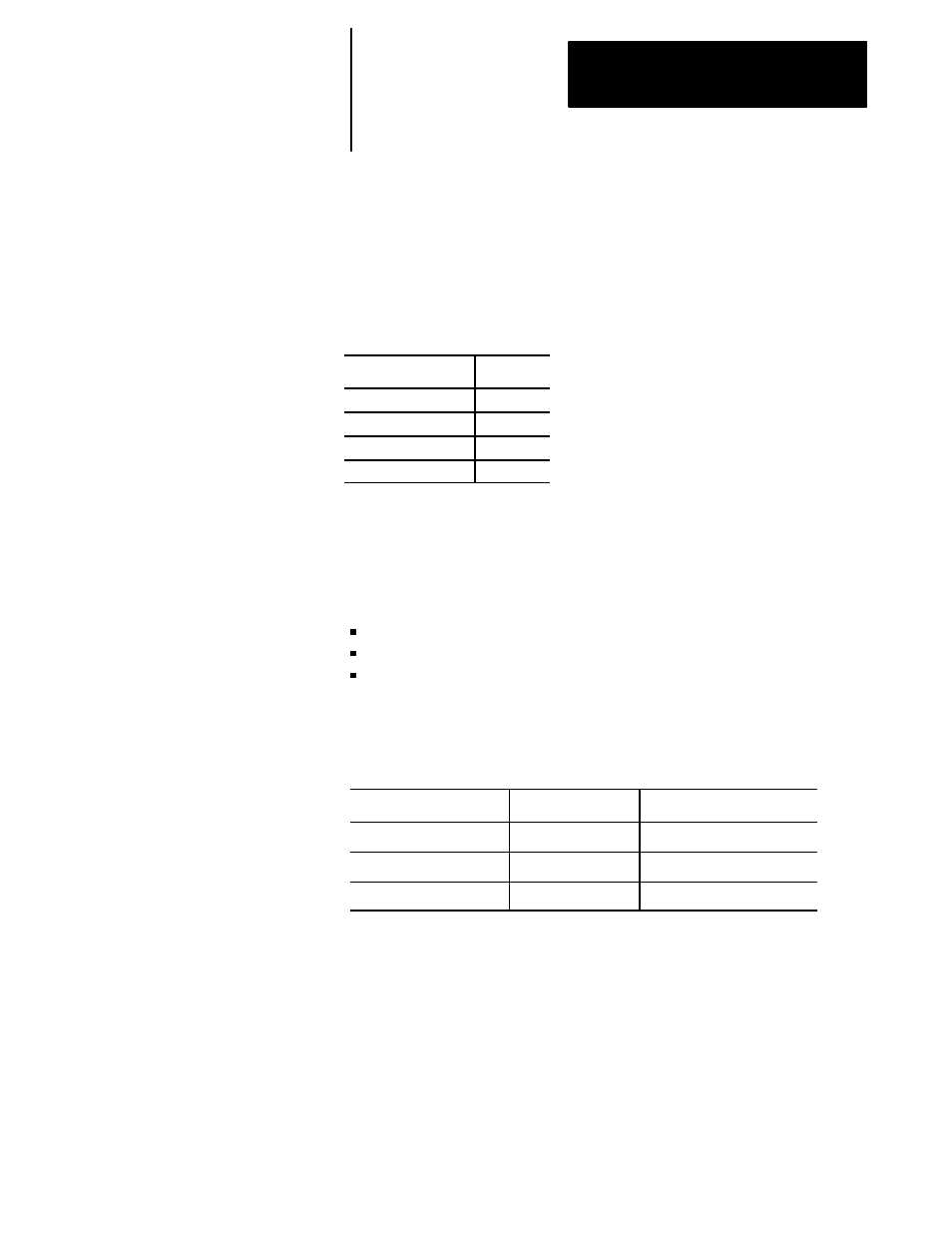

Table 17.A

Spindle Capabilities of the 9/Series Controls

Type of 9/Series Control

Number of Spindles

Spindle Type

9/230, 9/240

1

Primary

9/260

2

Primary, Auxiliary 2

9/290

3

Primary, Auxiliary 2, Auxiliary 3

Spindles 1, 2, and 3 must be configured in AMP, and the associated spindle

parameters must be set properly to provide for the required spindle

functions.

For systems with no spindle configured, simulated spindle feedback is

provided for the controlling spindle. This allows all control features that

require spindle feedback, i.e., IPR feedrate, threading, CSS, to simulate the

feedback from a spindle even through the AMPed system configuration

contained no spindle. The default is 4000 counts-per-rev device.

17.0

Chapter Overview

17.1

Controlling Spindle

(G12.1, G12.2, G12.3)