Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 441

Spindles

Chapter 17

17-5

Use the spindle directional M-codes to program each configured spindle

program controlled spindle rotation.

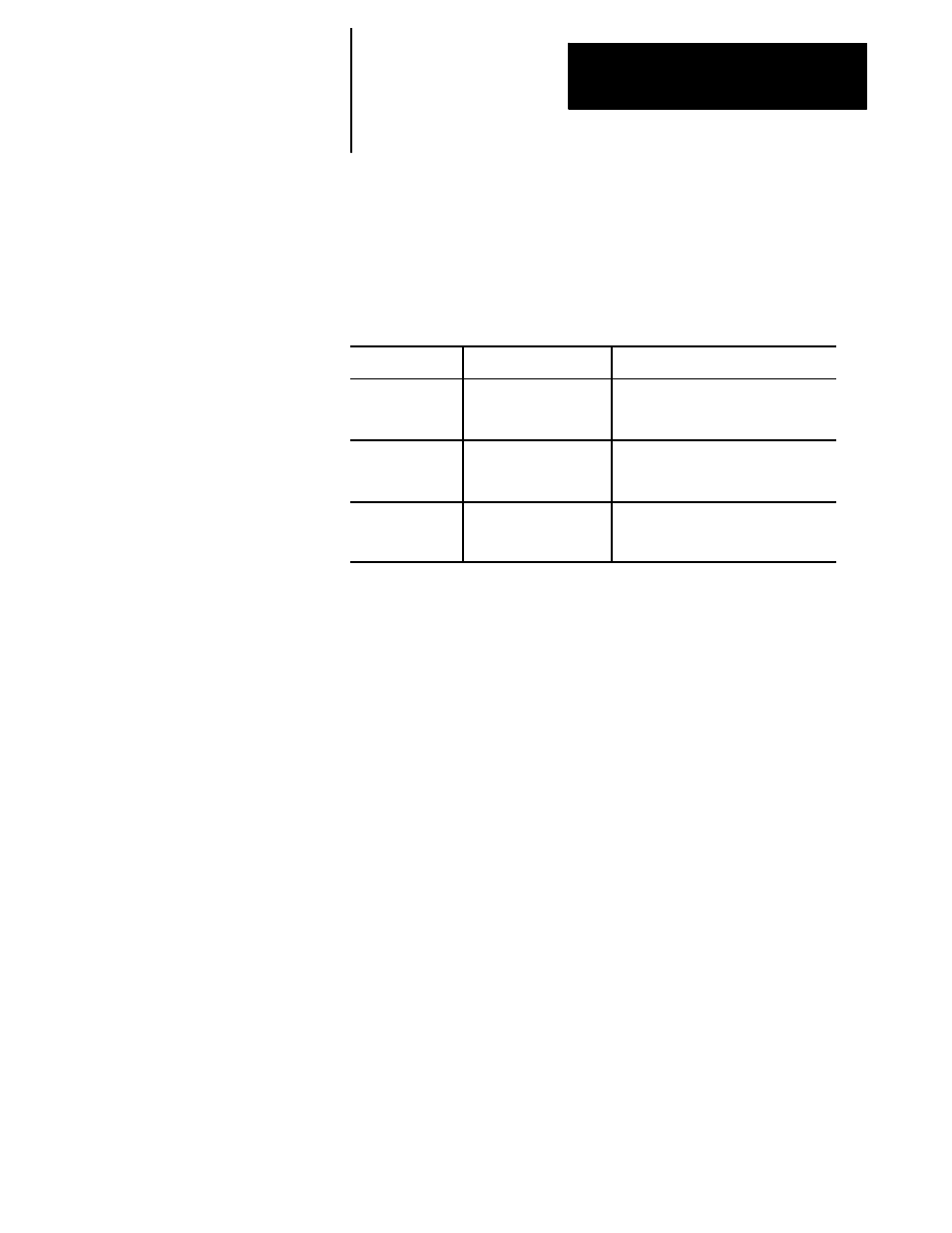

Table 17.B lists the spindle direction codes.

Table 17.B

Spindle Directional Codes

Spindle Type

Directional Code

This means:

Primary

M03

M04

M05

Spindle 1 clockwise

Spindle 1 counterclockwise

Spindle stop

Spindle 2

M03.2

M04.2

M05.2

Spindle 2 clockwise

Spindle 2 counterclockwise

Spindle 2 stop

Spindle 3

M03.3

M04.3

M05.3

Spindle 3 clockwise

Spindle 3 counterclockwise

Spindle 3 stop

Each spindle can have independent rotational control, and the rotational

speed is programmed by using the S-word. If a directional spindle code is

programmed in the same block as the S-word, then that S-word is applied

to each of the block’s associated spindles.

Example 17.1

9/290 Control with 3 Spindles Configured in AMP

N0001 M05

Spindle 1 stop

N0002 M05.2 M05.3

Spindles 2 & 3 stop

N0003 M03 M04.2 S150

Spindle 1 clockwise 150 rpm

Spindle 2 counterclockwise 150 rpm

N0004 M03.2 M04.3 S10

Spindle 2 clockwise 10 rpm

Spindle 3 clockwise 10 rpm

Important: On the 9/260 and 9/290 controls, if the auxiliary spindle

directional M-codes are programmed but the auxiliary spindles have not

been configured as active through AMP, these errors are given as decode

errors on any blocks that have directional M-codes of the associated

spindle programmed:

“SPINDLE 2 NOT CONFIGURED” and/or

“SPINDLE 3 NOT CONFIGURED”

17.3

Spindle Direction

(M03, M04, M05)