The software mtb panel can control these features – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 40

Basic Control Operation

Chapter 2

2-16

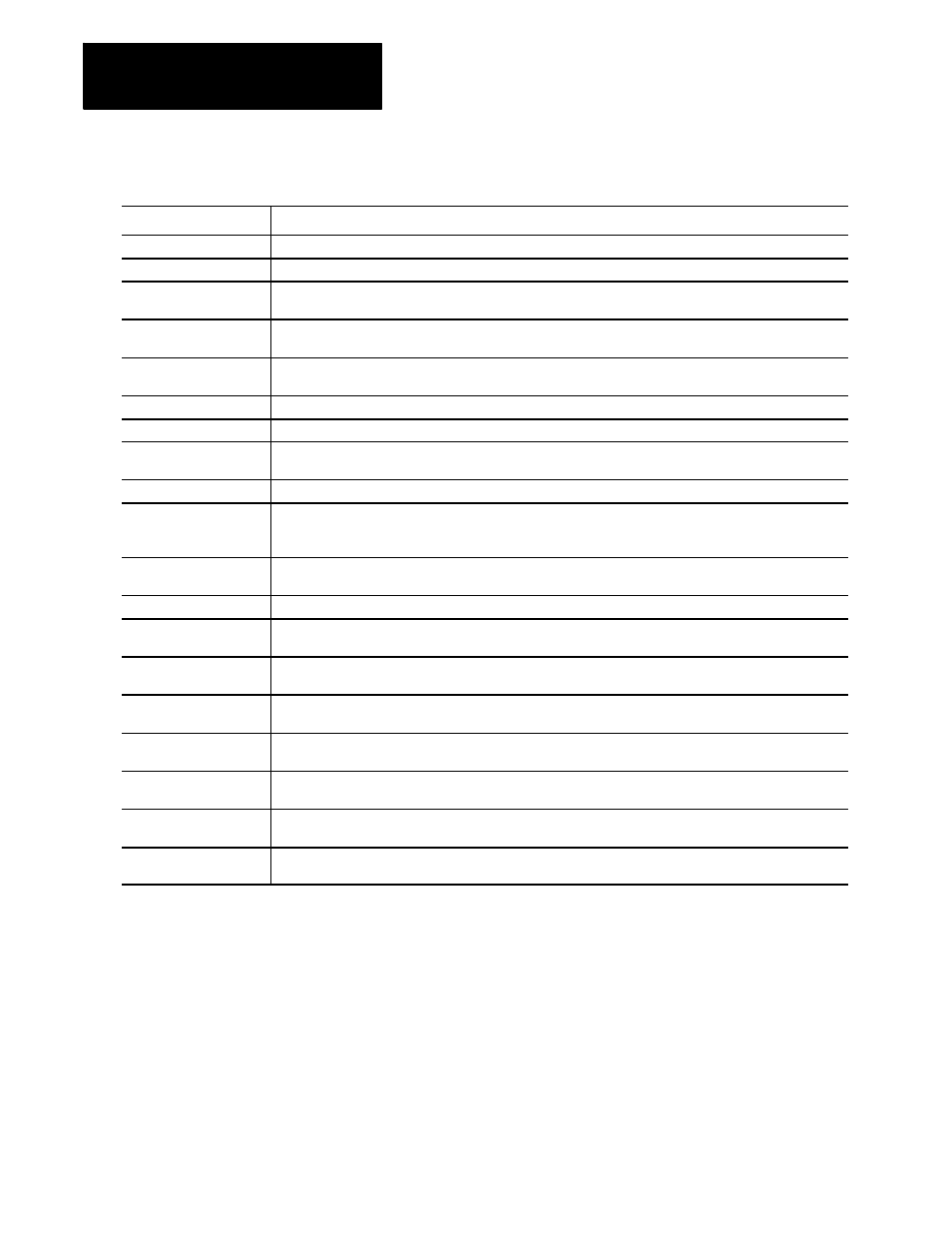

The software MTB panel can control these features:

Feature

Description

Mode Select

Select either Automatic, MDI, or Manual modes as the current operating mode of the control.

Rapid Traverse

This feature replaces the feedrate when executing a continuous jog move with the rapid feedrate.

Feedrate Override

Selects a feedrate override percentage for feedrates programmed with an F-word, in 10% increments within a

range of 0% to 150%. When set to 0%, the control is effectively in feedhold.

Rapid Feedrate Override

Selects the override for rapid feedrates. Select from F1, 25%, 50%, and 100%, where F1 is a rapid feedrate

override setting established in AMP by the system installer.

Spindle Direction

Selects spindle rotation, clockwise (CW), spindle stop (OFF), or counterclockwise (CCW). Is overridden by

any programmed spindle direction command.

Spindle Speed Override

Selects the override for programmed spindle speeds in 5% increments within a range of 50% to 120%.

Dry Run Mode

Places the control in Dry Run Mode. This replaces feedrates with the Dry Run feedrates. See chapter 7.

Block Delete

Allows the activation of the block delete feature “/ or /1”(See chapter 7). Block delete 2 -- 9 are not available

with the {FRONT PANEL}.

M-Function Lock

Allows select M-, S-, T-, and B-codes to be ignored. See chapter 7.

Optional Stop

This enables or disables the M01 optional stop code. When this feature is “ON,”an M01 in a part program

stops automatic execution. When this feature is “OFF,”an M01 in a part program is ignored. See chapter 10

for details on M01.

Single Block

The control executes or checks one block of a part program or MDI entry each time the

Mirror Image

Mirrors the axis commands in the part program around the selected axis. See chapter 14.

Axis Inhibit

Prevents axis commands from being executed. The control simulates axis motion on inhibited axes by using

Acc/Dec and feedrates; however, no actual axis motion for the inhibited axes is generated. See chapter 7.

Jog the Axes

Allows manual motions to be performed in any one of the jogging modes. See section 4.1. Multi-axis jogs

may not be performed by using the Software MTB feature.

Set Zero

Change the tool’s current position in the work coordinate system to 0 for the selected axis. This is done by

shifting the work coordinate system. See chapter 11.

Block Retrace

This allows up to 15 part program blocks to be retraced during program execution and allow the tool to

automatically re-execute these blocks. See chapter 7.

Jog Retract

Allow the tool to be manually jogged away from the part and then automatically return the tool to the part by

retracing the jogged moves. Up to 15 jog moves can be remembered. See chapter 7.

Cycle Start

The control begins or resumes part program execution, MDI program execution, or program check when you

press this button.

Cycle Stop

The control stops part program execution, or program check when you press this button. If pressed during the

execution of a program block, a cycle suspend state occurs.