5 automatic tool life management – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 503

Tool Control Functions

Chapter 20

20-19

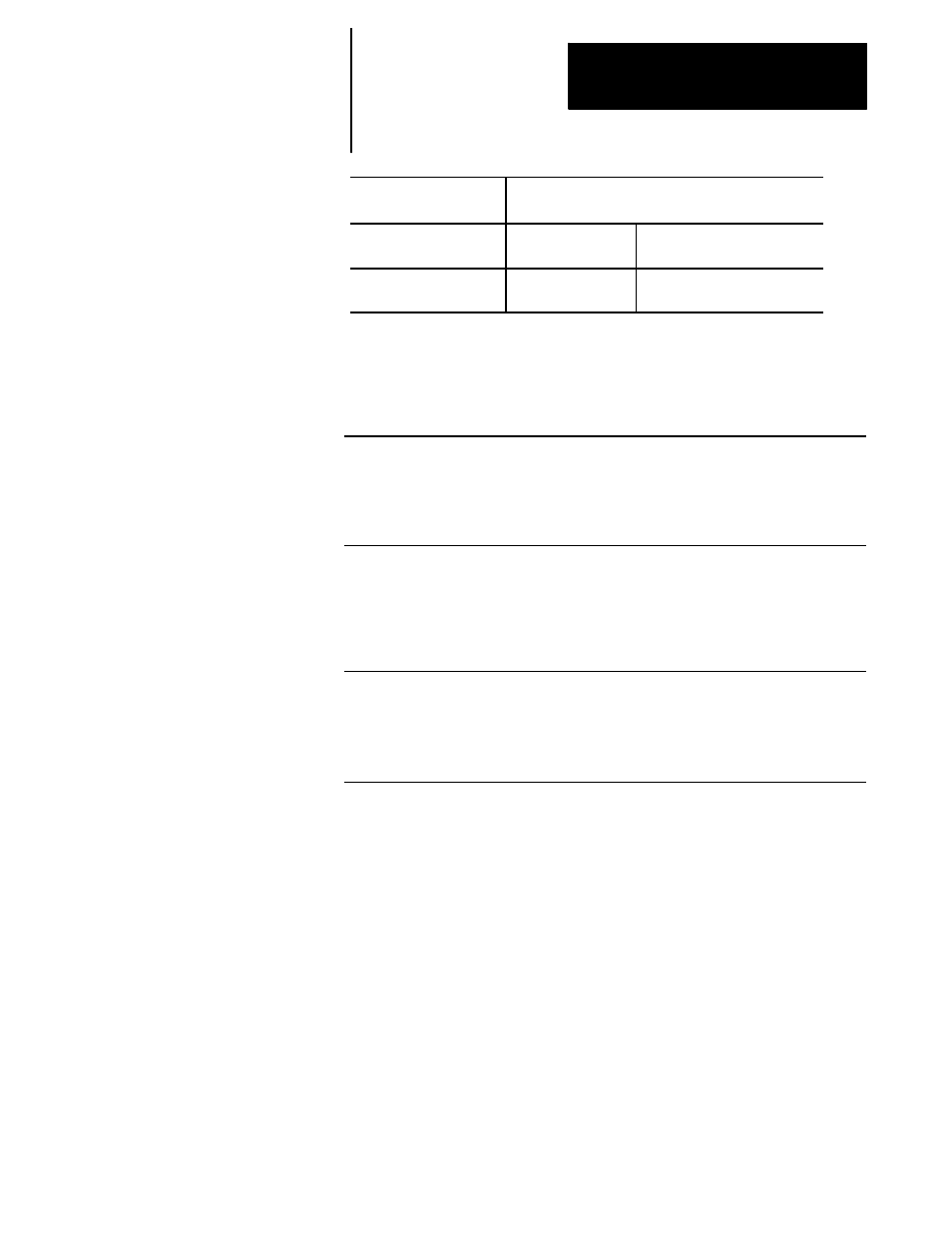

Value for the

L Parameter

Parameter Definition

P

R, X, Y, Z

L12

Geometry table

Offset Number

Tool radius geometry value

L13

Wear table

Offset Number

Tool radius wear value

Example 20.4

Replacing the Tool Offset Tables Through Programming (G90)

Assume a Z axis geometry value (tool length) of 2 for offset number 4.

N00001 G90;

N00002 G10 L10 P4 Z3;

Offset number 4 has a new value of 3 for

tool length.

N00003 G10 L10 P4 Z1;

Offset number 4 has a new value of 1 for

tool length.

Example 20.5

Modifying the Tool Offset Tables Through Programming (G91)

Assume a Z axis geometry value (tool length) of 2 for offset number 5.

N00001 G91;

N00002 G10 L11 P5 Z1;

Offset number 5 has a new value of 3 for

tool length wear.

N00003 G10 L11 P5 Z3;

Offset number 5 has a new value of 6 for

tool length wear

.

The automatic tool management feature is used to monitor the life of a

tool, determine when the tool should be replaced, and provide a

replacement tool when that tool is requested in a program.

This is done by assigning tools to selected groups. Then instead of calling

a specific tool in a program the programmer calls a tool group. The control

then selects the first tool assigned to that group. If that tool has exceeded

its entered tool life then a replacement tool is selected from the next tool

number assigned to that group. If that tool has exceeded its expected tool

life then the next tool in the group is selected. This continues until no

more tools are available in that tool group.

The correct tool length and tool radius offsets are assigned independently

for each tool in the group.

20.5

Automatic Tool Life

Management