4 circular pocket roughing using g88.1 – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 582

Using Pocket Milling Cycles

Chapter 22

22-10

If L is programmed, the tool plunges along the Z axis to the incremental

depth specified by the L parameter. If L is not programmed, the tool

plunges along the Z axis to the pocket depth specified by the Z parameter.

The plunge takes place at the plunge feedrate specified by the E parameter.

After the plunge operation a roughing cut is made at the feedrate specified

by the F parameter to the arc-center at the +X or +Y end of the slot.

A plunge to the next incremental L level or to the programmed Z level is

made. A roughing cut is made at the feedrate F to the arc-center at the -X

or -Y end of the slot. This process is repeated at each L level until the slot

is machined out. When the slot is machined out the control raises the tool

to the initial Z level plus the clearance amount and then moves it to the

pre-cycle position of the tool.

Use the G88.1 pocket milling roughing cycle to rough out a circular pocket

in a workpiece. This cycle makes multiple circular cuts at a programmed

width and depth.

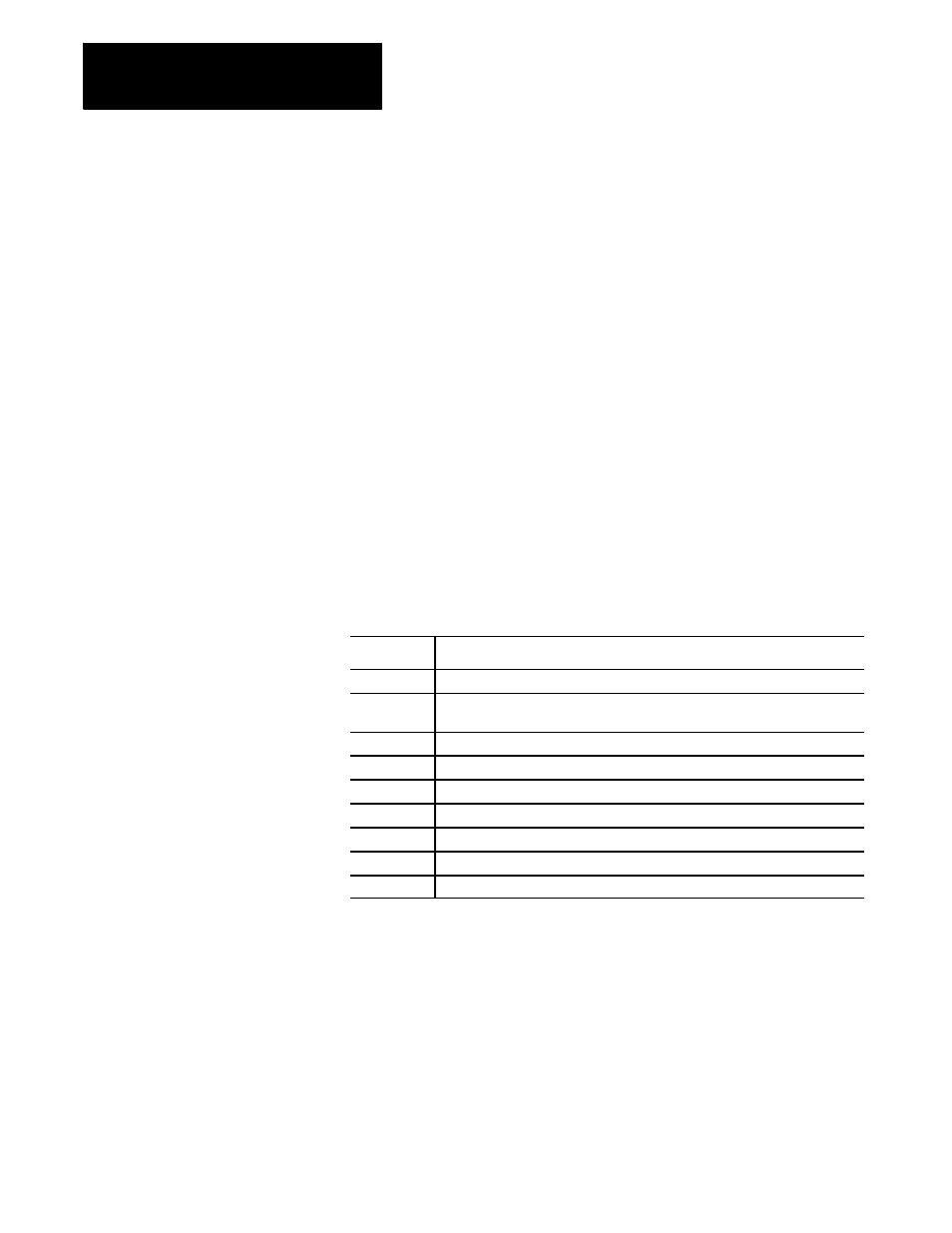

The G88.1 block used to rough out a circular pocket has this format:

G88.1

X__Y__Z__R__P__H__D__L__E__F__;

Where :

Is :

X Y

The coordinates that specify the center of the circular pocket.

Z

The coordinate (along the plunging axis) that specifies the bottom of the circular

pocket.

R

The radius of the circular pocket. This parameter must be programmed.

P

Direction of roughing cut.

H

Finish allowance.

D

Roughing cut thickness.

L

Incremental plunge depth.

E

Plunge feedrate.

F

Roughing feedrate.

22.1.4

Circular Pocket Roughing

Using G88.1