3 corner movement after generated blocks – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 559

Cutter Diameter Compensation

(G40, G41, G42)

Chapter 21

21-41

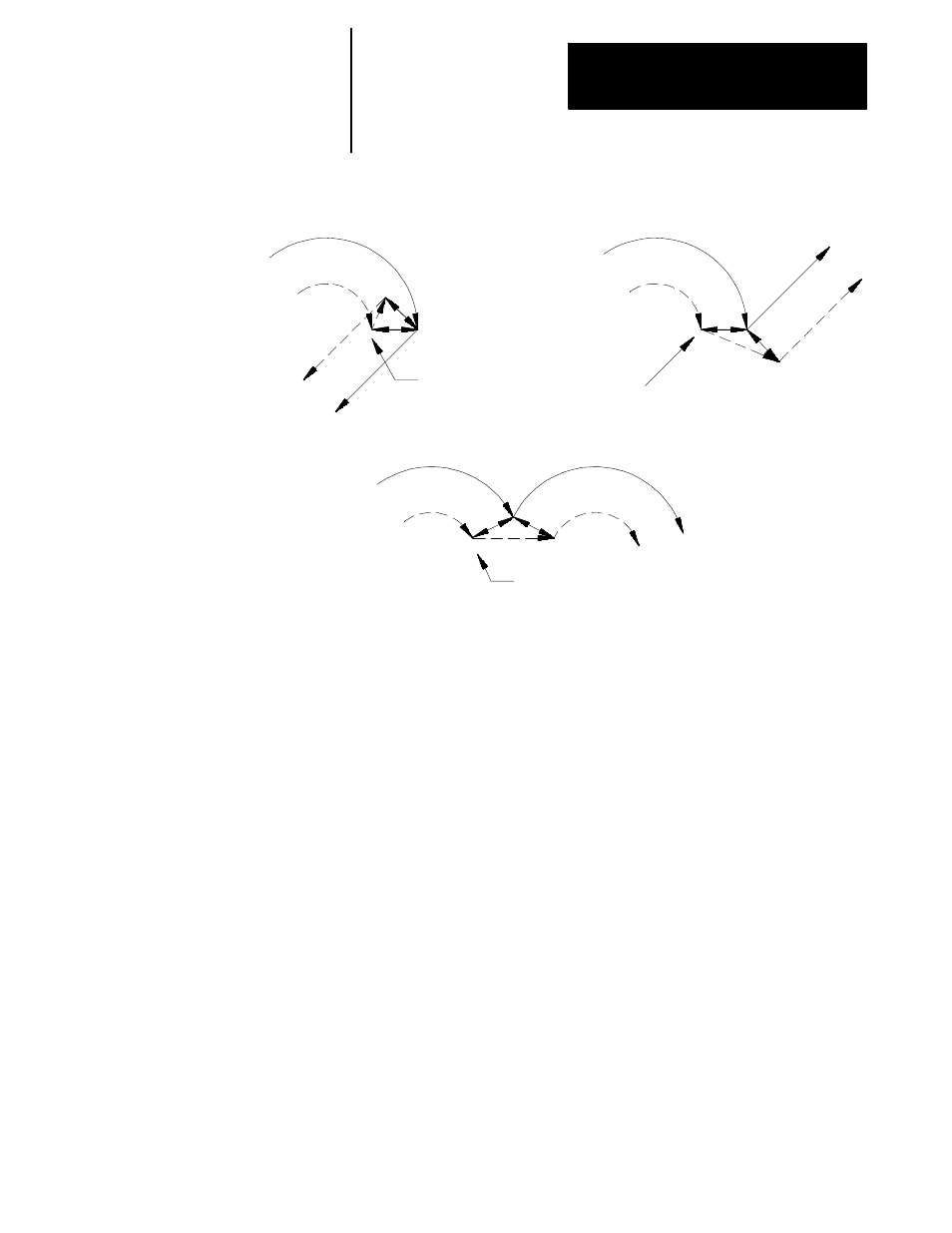

Figure 21.37

Too Many Non-Motion Blocks Following a Circular Move

Too many

non-motion

blocks here

Too many

non-motion

blocks here

Too many non-motion

blocks here

+

+

+

+

r

r

r

r

r

Programmed

path

Compensated

path G42

Programmed

path

Compensated

path G42

Programmed

path

Compensated

path G42

Frequently it is necessary for the control to generate motion blocks to

position the cutting tool in the proper alignment for a following

compensated cutting move. These blocks are generated to make sure that

the cutting tool remains at least one radius of the cutting tool away from

the programmed cutting path at all times.

When the control generates two motion blocks, the length of the first

generated block is checked against a minimum allowable length as

determined in AMP by the system installer. The coordinate values for the

current axes in the compensation plane are compared to the minimum

allowed value. If both are less than the allowed value, the control does not

execute the first generated block. The path of the second generated block

is then altered to position the cutting tool along a linear path to the original

end-point of the second generated block. See Figure 21.38 for a pictorial

representation.

21.6.3

Corner Movement After

Generated Blocks