Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 883

Error and System Messages

Appendix B

B-11

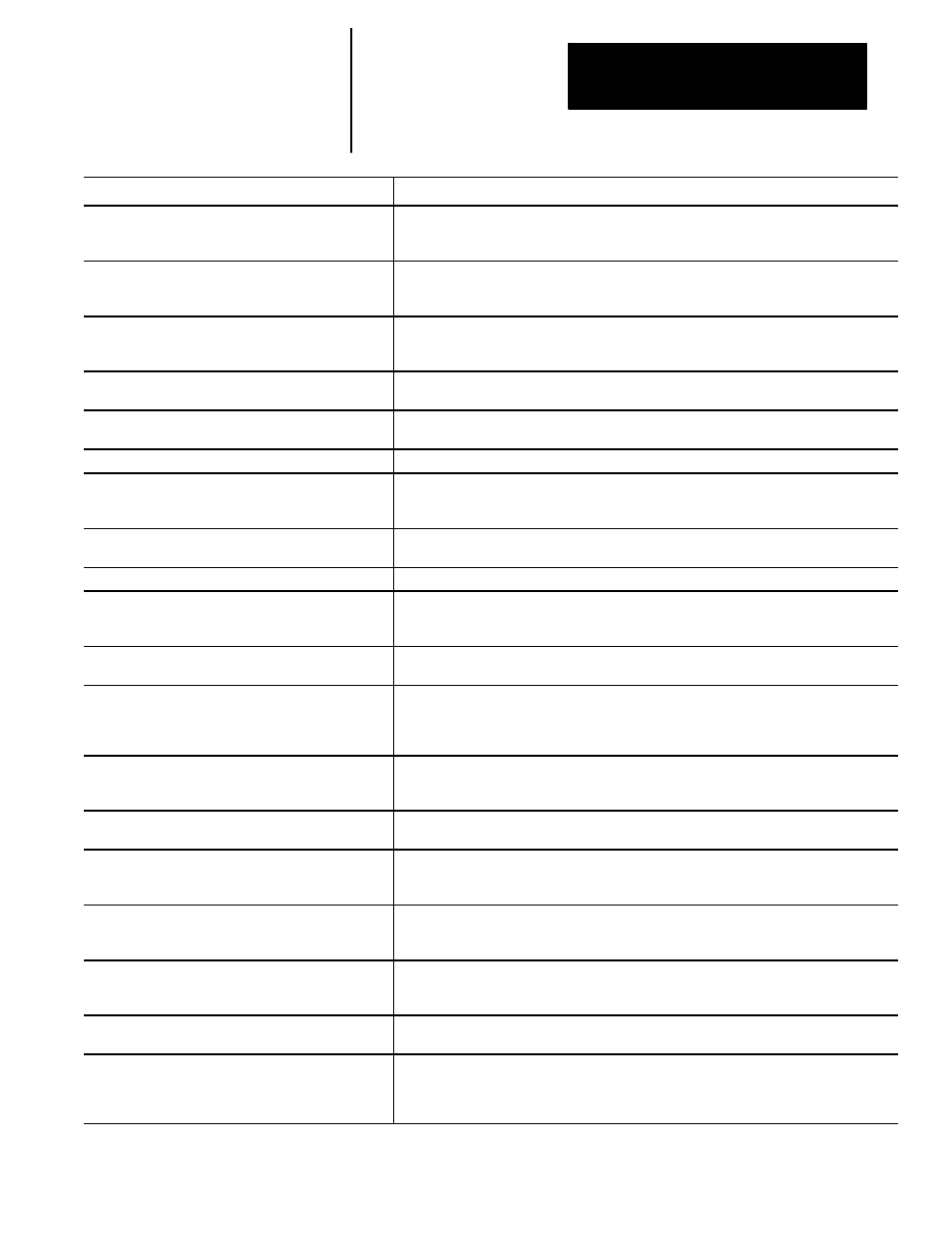

Message

Description

DEPTH PROBE TRAVEL LIMIT

The adaptive depth probe has moved to its AMPed travel limit. Note the value entered in AMP

is the adaptive depth probe deflection from the PAL determined probe zero point. It may not be

the actual total probe deflection.

DEPTH PROBE NOT SUPPORTED

A depth probe axis has been AMPed on an axis located on a servo card or a 9/230 that does

not support the adaptive depth feature. (analog servo rev < rev 0.10 or 3 axis 9/260 9/290

digital servo cards)

DESKEW OPTION NOT INSTALLED

If the AMPed name specifying the deskew slave servo is not zero, or the AMPed name

specifying the deskew master servo is not zero, and the option flag for deskew is zero, then the

system is held in E-Stop.

DEVICE ALREADY OPENED

An attempt was made to open a device for download or upload from ports A or B when the

device was already opened.

DEVICE NOT OPENED YET

The ready signal was not received when attempting to send data to or communicate with a

peripheral device connected to communication ports A or B.

DIAMETER AXIS MISCONFIGURED

An invalid axis has been configured as the diameter axis.

DIRECTORY CHANGED TO MAIN DIRECTORY

When a password is entered that does not have access to the protectable part program

directory and the protectable part program directory is currently selected, the control changes

the selected directory to the main directory.

DISP SELECT NOT ALLOWED

You can not use the display select functions while the online PAL search monitor utility is active.

Leave the search monitor utility before you try to select a display.

DIVIDE BY ZERO ERROR

A system software error has occurred. Consult Allen-Bradley customer support services.

(DO) NUMBER ALREADY USED

When executing a program, an attempt was made to activate a DO loop that has the same loop

identifier (DO 1, 2, or 3) as an already active loop in the program. Provided they are not nested

loops, the same loop identifier can be used more than once in a program .

(DO) RANGES INTERSECT

DO loops are improperly nested. A DO loop that is nested within another DO loop does not

have an END command before the original DO loop END occurs.

DRESS CANCEL DEFERRED TO G40

The in--process dresser cannot be canceled (made inactive) while dresser/wheel radius

compensation is active. If an attempt to cancel the in--process dresser is made, the control will

postpone the request until dresser/wheel radius compensation is canceled with a G40 (note that

M02, M30, and M99 can also cancel compensation).

DRESSER AXIS NOT ALLOWED

An attempt was made to program the dresser axis when the over the wheel dresser feature has

been activated through PAL. You cannot program the dresser axis when the over the wheel

dresser feature is active.

DRESSER FLANGE LIMIT REACHED

While dressing the grinding wheel the wheel size reached the entered flange limit. You should

stop dressing the wheel before damage to the wheel flange occurs.

DRESSER MINIMUM LIMIT REACHED

The current dressing operation would dress the grinding wheel below the minimum wheel

diameter as specified on the dresser status screen. This dressing operation will not be

performed.

DRESSER MISCONFIGURED

One of the AMP parameters for the dresser axis has not been configured properly. Either the

dresser axis, the vertical axis, or some other axis name is not a valid axis in the system. You

must re-configure your AMP. Refer to your AMP manual for details.

DRESSER MIS-POSITIONED

Wheel re-enable was requested with IPD active and wheel is more than 4 inch-programming

counts (hard-code amount) away from its previously active absolute position. Wheel dressing

does not start.

DRESSER NOT INITIALIZED

This error is generated if an attempt is made to activate the in--process dresser before the

dresser has been initialized through a wheel calibration operation.

DRESSER NOT/MIS CONFIGURED

The grinder over-the-wheel dresser feature issues this message when a wheel is initialized and

the dresser parameters in AMP have been misconfigured. This message is issued when the

dresser axis, dresser vertical axis, or dresser other axis has not been selected, or has been

AMPed to have common axes, or has been AMPed to be a non-existent axis name.