Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 877

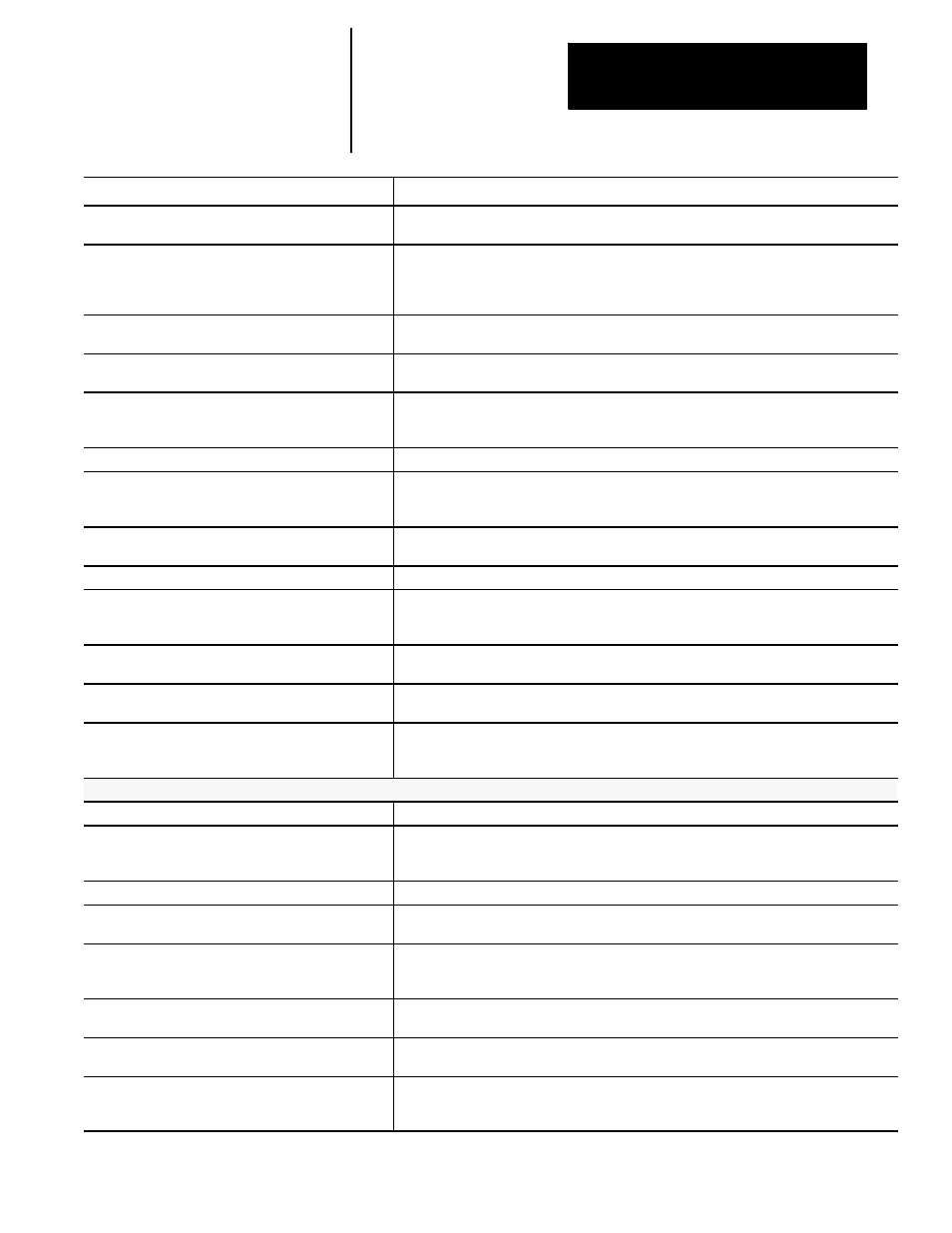

Error and System Messages

Appendix B

B-5

Message

Description

BAD RAM DISC SECTOR CHECKSUM ERROR

A RAM disk sector error was detected during the RAM checksum test at power-up. Attempt to

power-up again. If the error remains, contact Allen-Bradley customer support services.

BAD RECORD IN PROGRAM

This indicates a serious problem with the program. Attempt to open the program a second time.

If retry doesn’t work, you may have to delete the program. Typically this error is not caused by a

programmer or operator action. It is typically caused by an internal software error in the

program.

BAD STATE/TOKEN COMBINATION (PROGRAM

ERROR)

While attempting to decode the current block, a combination of characters caused a decode

error to occur. Check the characters in the current block for an illegal combination.

BATTERY FAILURE

The battery that provides backup of the RAM memory is not functioning; the voltage may be low.

The battery may be dead, removed, or poorly connected.

BLK DELETE CHG IGNORED ON PREPARED BLKS

A block-delete was activated while a program was executing. This change is ignored by the

control for blocks that have already been read into the control’s set-up buffer (see block

look-ahead in user’s manual).

BLOCK LENGTH ERROR

A block that exceeds the allowable maximum block length was programmed.

BLOCK RETRACE ABORTED

The block retrace operation being performed has been canceled. When

pressed, the control will return the tool along a linear path back to the start-point of the block

retrace operation.

BOOT DIRECTORY IS MISSING

The update utility failed to properly create the system boot directory. Retry the update. If the

error occurs again, contact your local Allen Bradley service.

BOOTSTRAP FAILED TO START

The bootstrap code did not send the “ok”signal to the main processor within the specified time.

BOTH AXES IN QPP PLANE NOT PRGMD

The second block of a currently executing QuickPath Plus two-block set does not contain both

required axis words in the current plane. Both axis words are required to correctly identify the

end-point of the second move.

BOTH LINES ARE PARALLEL

Both blocks of a two-block QPP sequence are parallel, and no mathematical intersection can be

computed.

BOTH PORTS ARE BUSY

An attempt was made to use or monitor communication ports A or B when neither were

available.

BUSY, REQUEST IGNORED

You have requested an operation while the control is currently executing some other higher

priority function. The control must first complete the higher priority task before your new task

can be performed.

C

CALLED 7300 PATTERN NAME IS BAD

The 7300 pattern name that is called by a part program does not exist .

CANCEL/REMOVE OFFSET BEFORE AXIS CHANGE

You have attempted to change the active tool length axis while an length offset is currently

active on that axis. You must cancel tool length offsets before you are allowed to change the

active tool length axis.

CANNOT (GOTO) TO INSIDE A (DO)

A (GOTO) command cannot transfer execution to a block which is located within a (DO) loop.

CANNOT ACCESS REMOTE VARIABLE

Variable name is invalid. Check the fields for CNC name and remote name, and make sure they

are in the correct format.

CANNOT ACTIVATE - OPEN PROGRAM

An attempt was made to activate a program for execution when it was still open for an editing

operation. Before it can be activated for automatic execution, it is necessary to press the {EXIT

EDITOR} softkey from the edit menu to close a program being edited.

CANNOT ACTIVATE RAM PARTITION

The RAM disk has been corrupted. Attempt to perform a “REFORMAT”operation. If this is

unsuccessful, consult Allen-Bradley customer support services.

CANNOT ASSIGN IN CURRENT MODE

An attempt was made to modify a paramacro parameter that cannot be modified when the cutter

compensation or TTRC feature is active.

CANNOT CALCULATE - PROMPT PRESENT

An attempt to perform a calculate operation was made when some other prompt was present on

line 2 of the CRT. Before the control will allow a calculation to be made, it is necessary to

remove any prompts from line 2 .