Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 778

Chapter 30

Using a 9/Series Dual--processing System

30-10

Important: You cannot use these synchronization with setup M--codes

when cutter compensation is active. Use one of the simple synchronization

M--codes or turn off cutter compensation before programming the

synchronization with setup M--code.

Coordinating Synchronization Between Processes

Remember that both processes are executing coordinated part programs.

Failing to coordinate part programs correctly can result in the processes

executing different synchronization codes and mutually locking each other

out.

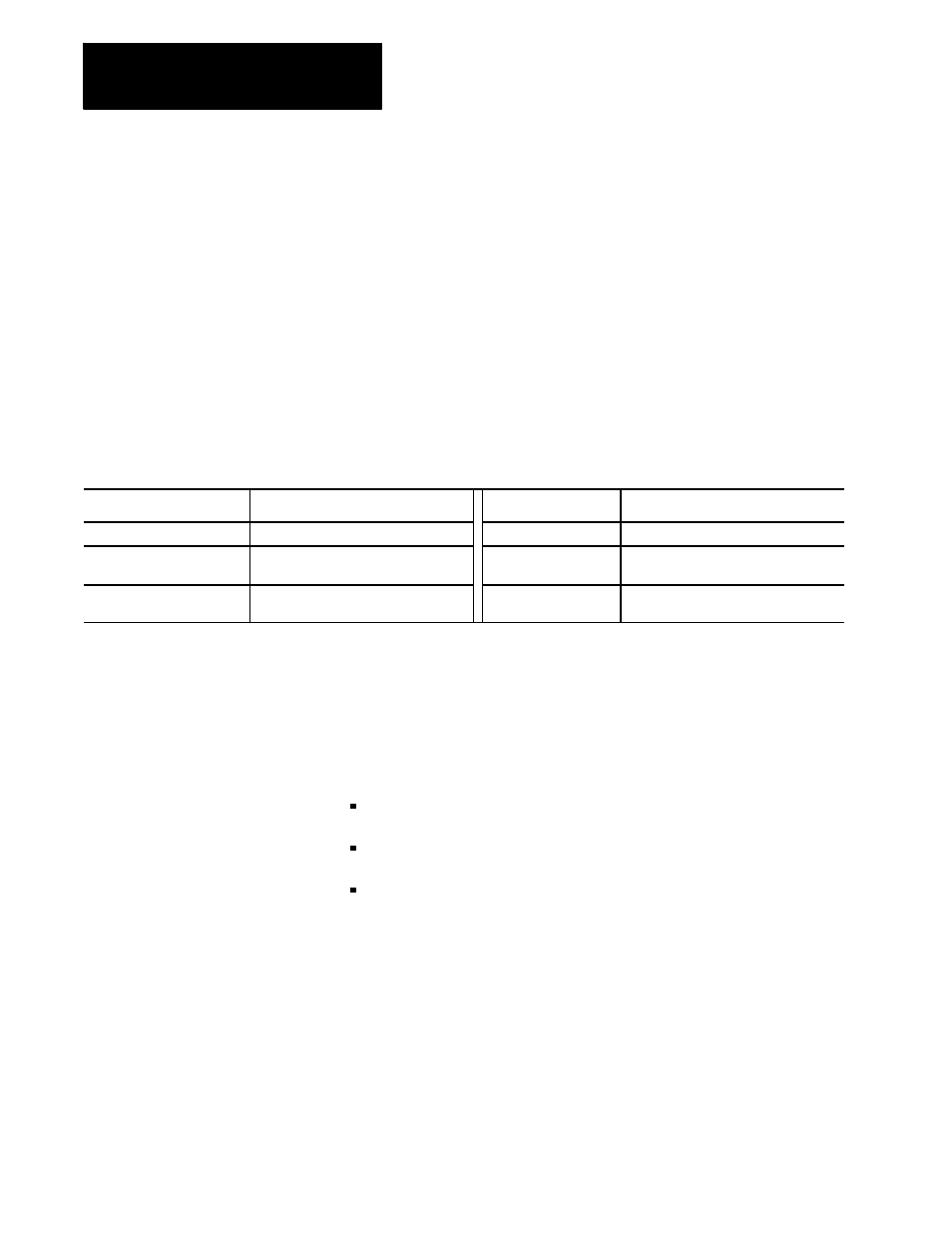

Example 30.4

Mismatched Synchronization Codes

Process 1

Comment

Process 2

Comment

N7 #7100=25;

N32 M101

Process 2 paused, waiting for M101 in

process 1.

N8 M100

Process 1 paused, waiting for M100 in

process 2.

In Example 30.4, both processes are paused indefinitely, waiting for the

other process to execute the corresponding M-code. The control displays

an error message when this situation occurs, indicating that execution of

that block has been suspended until it synchronizes with the other process.

Perform a Block Reset to allow part program execution to continue.

You can help prevent this situation by:

being consistent and always start your programs with the same

synchronization M-codes

making certain each program contains the same number of

synchronization M-codes

making sure the synchronization M-codes are placed in the same

corresponding order between processes