3 slot roughing using g88.1, Important – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 580

Using Pocket Milling Cycles

Chapter 22

22-8

Use the G88.1 pocket milling roughing cycle to rough out a slot in a

workpiece. This cycle makes multiple cuts at a programmed length and

depth.

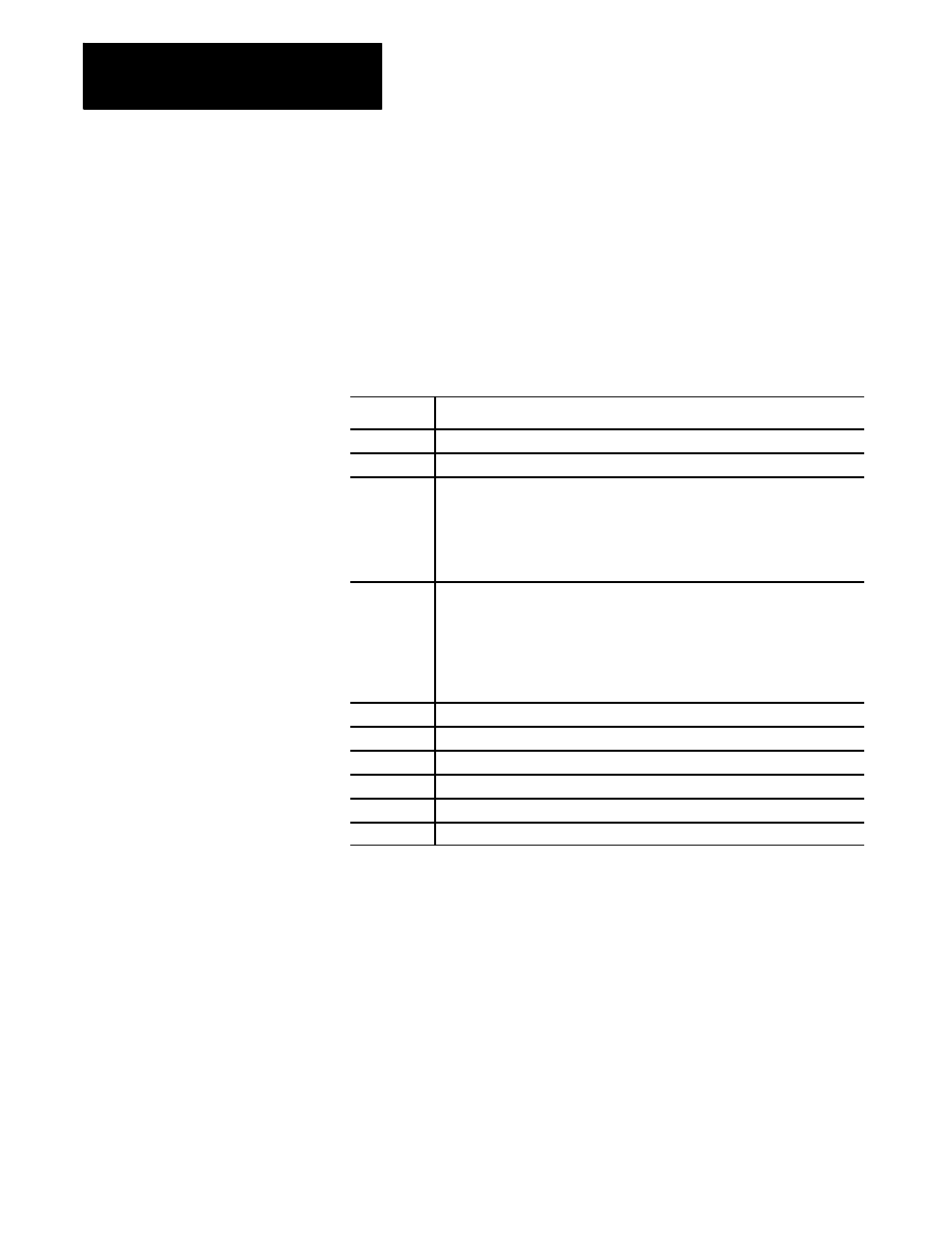

The G88.1 block used to rough out a slot has this format:

G88.1

X__Y__Z__I__R__P__H__D__L__E__F__; (X axis slot)

or

G88.1

X__Y__Z__J__R__P__H__D__L__E__F__; (Y axis slot)

Where :

Is :

X Y

The coordinates that specify the center of the slot.

Z

The coordinate (along the plunging axis) that specifies the bottom of the slot.

I J

The length of the slot as measured from the points where the axis intersects the

arc at each end of the slot. I specifies the length of a X axis slot. J specifies the

length of a Y axis slot. These are unsigned incremental values.

Important:

It is assumed that I and J are assigned in AMP as the integrand

axis names that correspond to the X and Y axes respectively.

R

The radius of the arc at each end of the slot. The radius equals the slot-width/2.

If not programmed, the control uses the tool radius value.

Important:

When roughing out a slot, the tool radius can not exceed the

radius of the arc at each end of the slot. If it does, the control enters Cycle-Stop

mode and displays the error message “TOOL RADIUS TOO LARGE”on the

CRT.

P

Direction of roughing cut.

H

Finish allowance.

D

Roughing cut thickness.

L

Incremental plunge depth.

E

Plunge feedrate.

F

Roughing feedrate.

22.1.3

Slot Roughing Using G88.1