Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 915

Error and System Messages

Appendix B

B-43

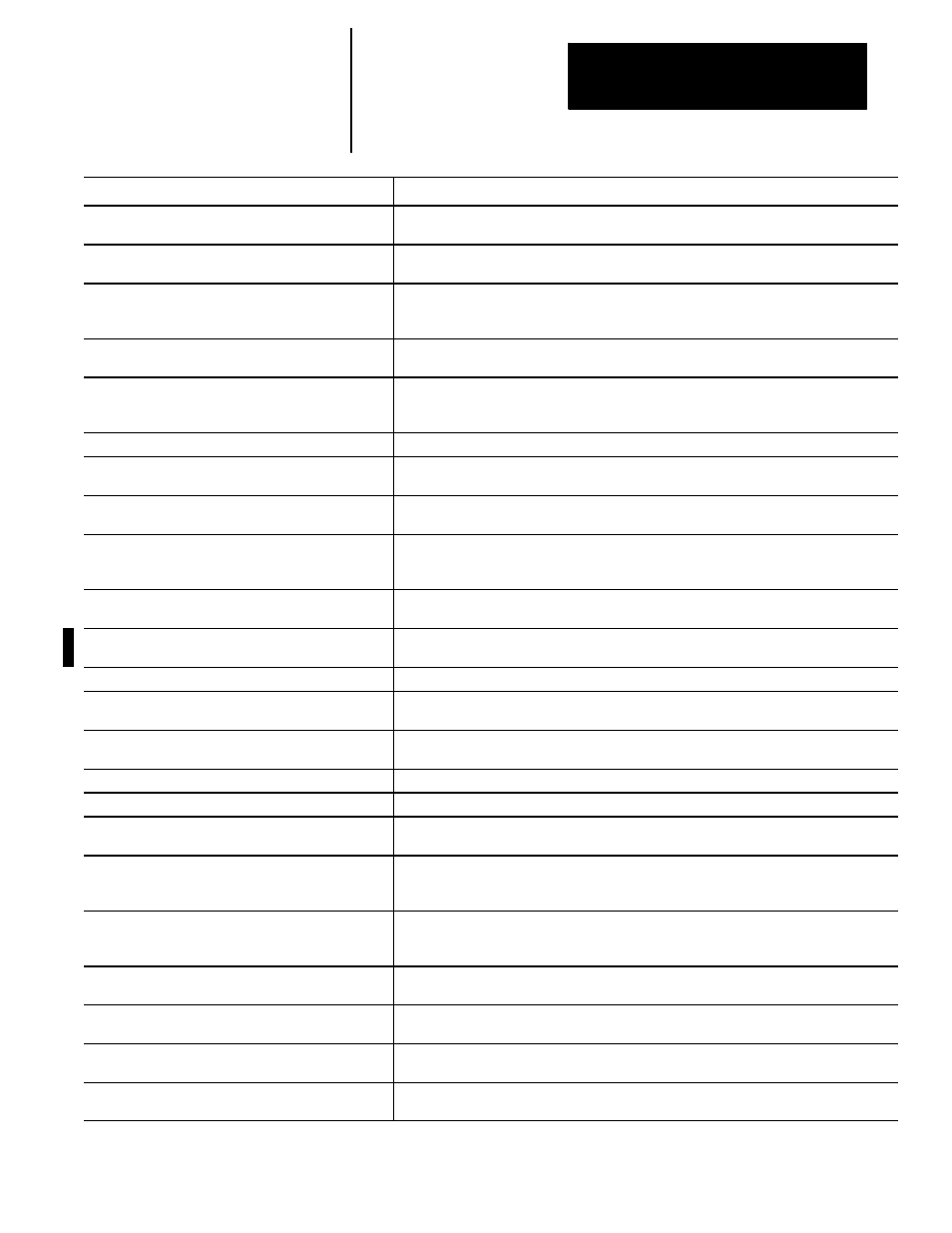

Message

Description

THREAD LEAD IS ZERO

No thread lead has been programmed in a block that calls for thread cutting. Thread lead is

programmed with either an F- or an E-word.

THREAD PULLOUT DISTANCE TOO LARGE

The programmed threading pullout distance is larger than the programmed distance of the

thread departure.

THREAD PULLOUT STOPPED AT I--PLANE

The chamfer block of a threading cycle is shortened so that the combination of pullout angle and

pullout distance does not cause the retract in axis 1 to go beyond the I--plane. The AMP pullout

angle is still used for the chamfer.

THREADING DISTANCE IS ZERO

A threading cycle has been programmed with no thread. Program an end-point or an end-point

different from the start-point.

TIME-OUT OCCURRED WHILE WAITING FOR INPUT

When downloading AMP or PAL from the ODS workstation to the control, the message OKAY

TO DOWNLOAD? (Y/N): appears on the control screen. If you do not respond within an allowed

time, this error will appear.

TIMER MUST START WITH #

You have used incorrect search string syntax in the PAL search monitor utility.

TOO MANY ( [ ) IN EXPRESSION

The control has found an unmatched number of [] in a program block or calculator operation. All

left brackets “[”must have a corresponding right bracket “]”.

TOO MANY ( ] ) IN EXPRESSION

The control has found an unmatched number of [] in a program block or calculator operation. All

right brackets “]”must have a corresponding left bracket “[”.

TOO MANY 7300 PATTERNS IN MEMORY

An attempt was made to enter a 7300 pattern into the control’s memory when the internal

cross-reference table of pattern repeat names was full. The internal cross-reference table of

pattern repeat names can only hold 20 pattern repeat names.

TOO MANY ACTIVE PROCESSES CONFIGURED

An AMP has been loaded that has too many actively configured processes for this controller

model. The 260 series and the dual lathe can have only 2 active processes.

TOO MANY AXES AMPED FOR HARDWARE

An AMP has been loaded that has too many configured axes for this controller model. The

9/440 series can have only up to 6 axes.

TOO MANY AXES PROGRAMMED

Too many axis letters were programmed in a fixed cycle block.

TOO MANY AXES SELECTED FOR DISPLAY

When using the {AXIS SELECT} softkey, you can display only 6 axes. If you attempt to display

more than 6 axes, this message is displayed.

TOO MANY CODES IN SYNCH BLOCK

Synch codes must be in a block by themselves, except for an N- or O-word. (9/260-9/290 dual

lathe only)

TOO MANY DECIMAL POINTS

A word or parameter value has been programmed with two or more decimal points.

TOO MANY DEVICES ON I/O RING

The I/O ring cannot support the number of devices that has been connected.

TOO MANY EXPRESSION NESTS

The maximum number of nested expressions is 25; for example, [P3+[P4+[P5]]] has 3

expressions nests.

TOO MANY G67’S

A G67 cancel modal paramacro code was executed when no modal paramacro was active.

This is typically caused when there are fewer nested modal paramacros than the programmer

expected.

TOO MANY I-J-K SETS

An attempt was made to define a local paramacro parameter that is greater than #33 using I,J,K,

argument sets. A maximum of 10 different I, J, K, sets may be programmed for each set of local

parameters.

TOO MANY MACRO CALLS

The maximum number of nested paramacros was reached. Only 4 paramacros can be active at

any one time.

TOO MANY MOTORS AMPED ON 1ST BOARD

The AMP parameter for the number of motors on the first servo board is larger than the number

of axes in the system.

TOO MANY NESTED (DO) COMMANDS

More than the allowable number paramacro DO loops are active at one time. A maximum of 3

nested DO loops are allowed.

TOO MANY NONMOTION BLOCKS-DEADLOCK

There were too many non-motion blocks encountered during the look-ahead for cutter

compensation or QPP. Consult Allen-Bradley customer support services.