Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 913

Error and System Messages

Appendix B

B-41

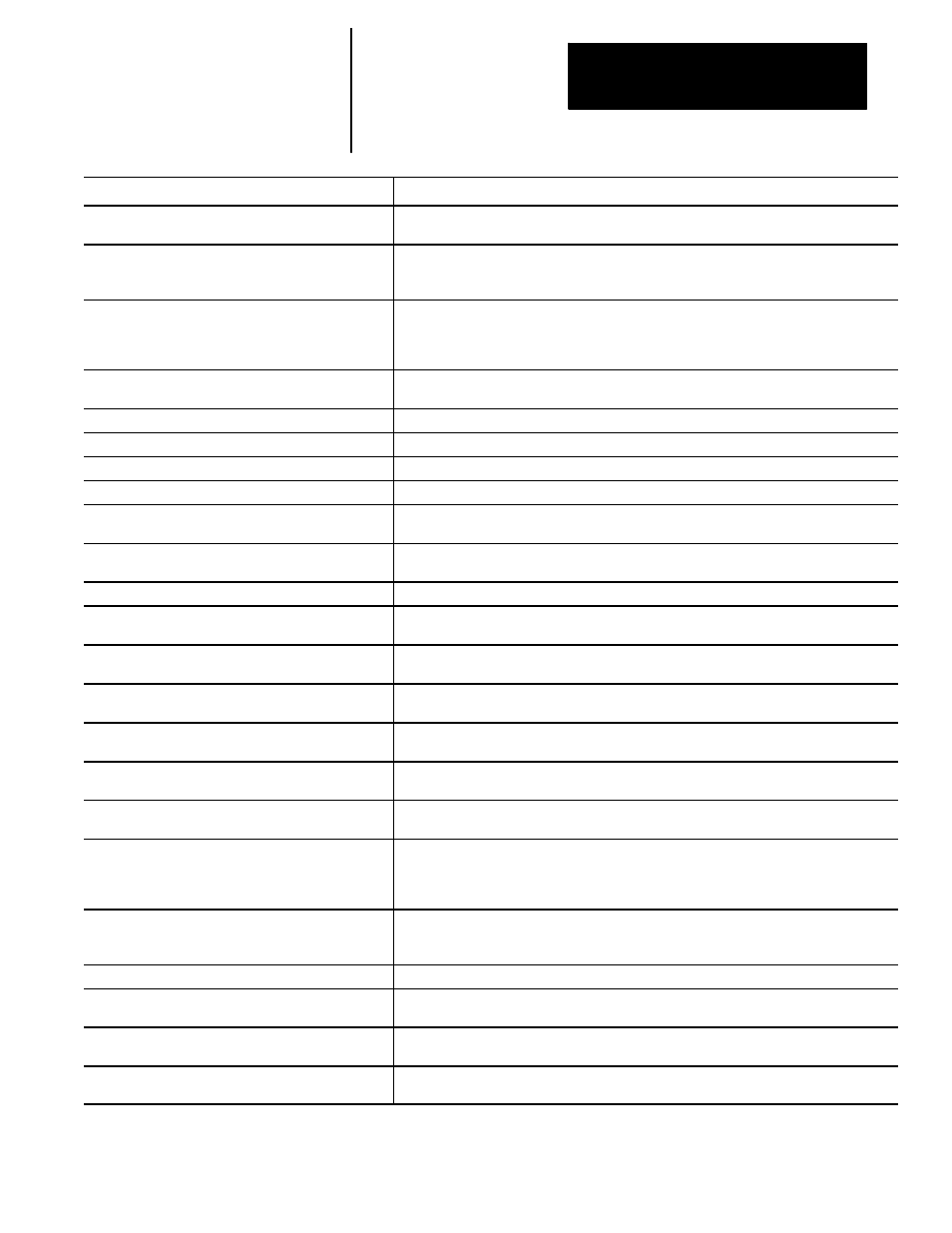

Message

Description

SPINDLE IS CLAMPED

An attempt was made to program a block containing a spindle code other than an M05 while the

PAL servo clamp request flag for the spindle was set.

SPINDLE MODES INCOMPATIBLE

An attempt was made to enter virtual mode when the spindle that is used for this mode is

synchronized as the follower spindle or an attempt was made to perform end face milling during

synchronization.

SPINDLE MOTOR SPEED TOO HIGH

When using a 1326 motor as a spindle, feedback resolution combined with your configured

maximum spindle speed would return feedback counts faster than the control can reliably

decode. Either reduce the maximum configured spindle speed, or reduce the configured

feedback counts for the spindle in AMP.

SPINDLE MUST BE THE LAST SERVO

When the system is AMPed, the spindle must be assigned to the first available port after all axes

have been assigned.

SPINDLE NOT ASSIGNED

A spindle axis was AMPed, but not assigned to any process.

SPINDLE ORDER ERROR, AMP AUX. 2 SECOND

AMP order of spindles must be primary spindle, aux. spindle 2, aux. spindle 3.

SPINDLE ORDER ERROR, AMP AUX. 3 THIRD

AMP order of spindles must be primary spindle, aux. spindle 2, aux. spindle 3.

SPINDLE ORDER ERROR, AMP PRIMARY 1ST

AMP order of spindles must be primary spindle, aux. spindle 2, aux. spindle 3.

SPINDLE SYNC NOT CONFIGURED

The programmer attempted to enter synchronized spindle mode before it was configured in

AMP.

SPINDLE SYNC UNAVAILABLE THIS PROCESS

An attempt was made to enter synchronized spindle mode on a dual--process control when the

process was not yet configured for both spindles in the synchronized pair.

SQUARE ROOT OF NEGATIVE ERROR

Internal math error has occurred; contact Allen-Bradley customer support services.

SQUARE ROOT OF NEGATIVE INVALID

An attempt was made to determine the square root of a negative number using the calculator or

through a paramacro SQRT command.

STORED PASSWORD LIST TO BACKUP

This message appears after the password list has been successfully stored to the control’s

backup memory.

STORING TO BACKUP - PLEASE WAIT

This message appears whenever AMP or axis calibration data in RAM is being stored in backup

memory.

SYMBOL NAME FORMAT ERROR

Check the remote symbol and CNC symbol to make sure they exist on both remote and CNC.

Check the table of the read only or write only variables.

SYMBOL NOT FOUND

Check the remote symbol and CNC symbol to make sure they exist on both remote and CNC.

Check the table of the read only or write only variables.

SYNCHRONIZATION DEADLOCK

A synchronization code is activated and caused the activating process to wait on a process that

is already waiting.

SYNCH SPINDLES MISCONFIGURED

Causes for this could be: only one spindle (either controlling or follower) was defined in the

synchronized spindle pair, you exceeded the simple feedback ratio limitation of 10 (e.g., 11:1 or

2:13), or on a multiprocess system, one (or both) of the spindles in the synch pair is currently not

available to the process making the synchronization request.

SYNCH SPINDLES REQUIRE FEEDBACK

One or both of the spindles, configured in AMP as a member of a synchronized pair, did not

have feedback. Both spindles in a synchronized pair must be equipped with an AMP configured

feedback device.

SYNTAX ERROR (COMMA)

A missing comma or an extra comma was found in the program block.

SYSTEM DIAGNOSTIC #1

An illegal parameter was passed into a switch statement (mid-program start) in the control

software. Contact Allen-Bradley customer support services.

SYSTEM DIAGNOSTIC #2

An illegal parameter was passed into a switch statement (ASCII buffer task) in the control

software. Contact Allen-Bradley customer support services.

SYSTEM DIAGNOSTIC #3

An illegal parameter was passed into a switch statement (ASCII buffer task) in the control

software. Contact Allen-Bradley customer support services.