Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 698

Skip, Gauge, and Probing Cycles

Chapter 27

27-24

The adaptive depth probe position is zeroed automatically at power turn

on. In the event that you must re-zero the probe the system installer can

write PAL to enable you to zero the probe any time the adaptive depth axis

is not in motion. Refer to your system installers documentation on using

$ADPCLR.

WARNING: We strongly recommend that you require (either

through PAL or some other procedure) a manual probe zeroing

operation be performed after every power up. This will help

prevent problems that can occur if an invalid zero point is

established at power up.

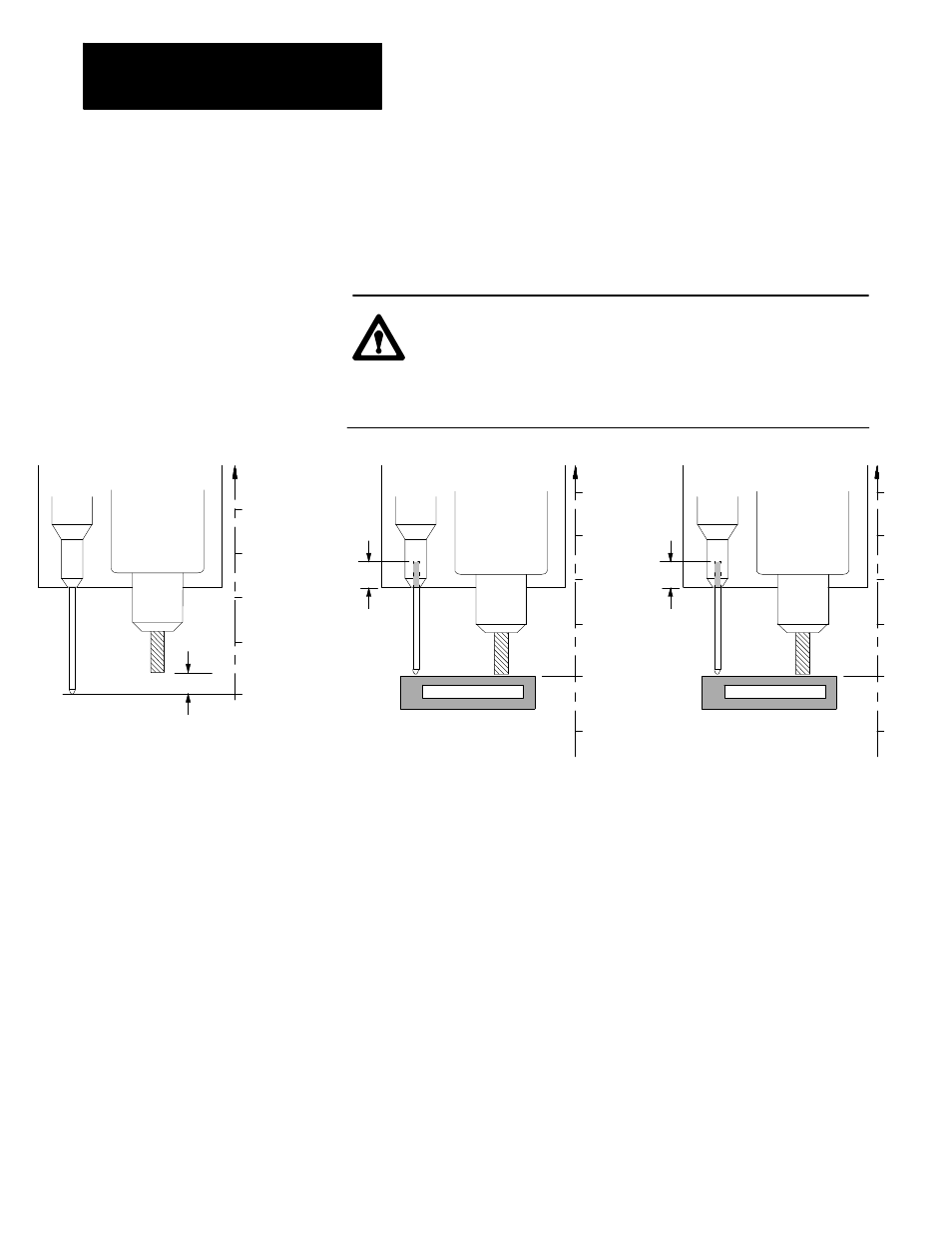

Spindle

Motor

20

15

10

5

0

Spindle

Motor

Probe

Probe zero position after power up is

not aligned with tool tip. Typically no

probe deflection exists at power up.

Axis monitor page for depth probe:

Following error = 0.0000

Probe position = 0.0000

20

15

10

5

0

--5

Touch off the part to align tool tip with

probe tip.

Axis monitor page for depth probe:

Following error = +0.2000

Probe position = --0.2000

Touch Off Surface

Probe

Probe Axis

Probe Axis

2

2

Spindle

Motor

20

15

10

5

0

--5

After touching off the part and using PAL

to zero the probe, the zero position of the

probe is aligned with the part surface.

Axis monitor page for depth probe:

Following error = 0.0000

Probe position = 0.0000

Touch Off Surface

Probe

Probe Axis

2

Probe counts that occur when the probe deflection is less than zero will not

trip the probe. Since the probe is not tripped in this range, the control will

still use the axis feedback for positioning. Probe fired only occurs after the

probe position register becomes positive (deflection reaches the zero point)

plus the number of counts required for probe fired (probe trigger

tolerance).