Template 4: deep hole drill cycle, chip break, Chapter 31 – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 834

Using Transfer Line Cycles

Chapter 31

31-32

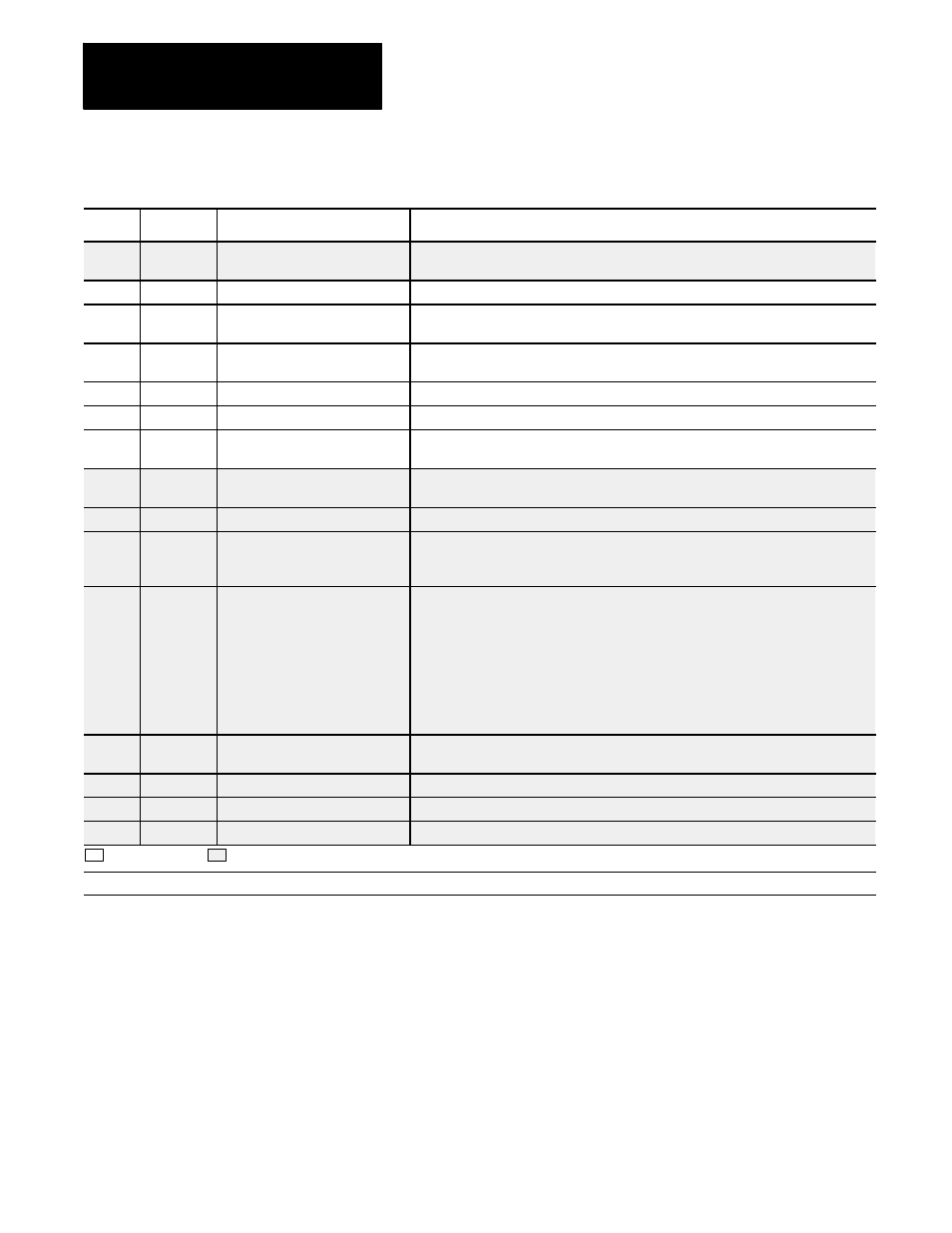

Template 4: Deep Hole Drill Cycle, Chip Break

Letter

Paramacro

Label

Description

G

500

G90/91

G-codes G90 or G91 for absolute or incremental modes. At this time only absolute

mode, G90, is available.

X,Y

501, 502

HOLE POSITION X, Y

The location to which the tool moves before it begins a drilling operation.

X

503

DEPTH OF HOLE

The location to which the tool drills into the part. If the cycle uses adaptive depth, this

position needs to be beyond the adaptive depth increment.

R

504

CLEAR POSITION

The location that the tool retracts to after an operation. It is completely free of the part.

This also known as the R plane.

Q

505

INFEED AMOUNT

This defines the infeed amount for each step into the hole

X,Y

506, 507

RETURN POSITION X, Y

The location where the controls starts and stops a cycle.

F

508

FEEDRATE

The feedrate for drilling/boring operations. This is also the maximum feedrate for

operations that use adaptive depth.

P

509

AMOUNT OF DWELL

The amount of time the axis pauses before it retracts from the hole; measured in

seconds.

X

510

TOOL CHANGE POSITION

The location where the controls starts and stops a cycle.

E

511

ADAPTIVE FEED MINIMUM

This is the minimum feedrate at which the control performs an adaptive feed operation.

The control will try to maintain this minimum feedrate, even if it means increasing the

adaptive feed torque percent.

Q

512

ADAPTIVE FEED TORQUE %

This is the amount of the selected servo’s continuous rated torque as entered in AMP by

your system installer. Valid ranges are from 1 to 150% of the servo’s rated torque.

Refer to your system installer’s documentation for details on the rated torque of the

servos in your system.

Important: The torque amount applied by the servo is not the cutting force. It is the

torque applied by the servo to the axis. You must calculate the equivalent cutting force

based on your machine dynamics (motor rated torque, lead screw pitch, gearing, tool

dimensions, etc...).

I

513

HARD STOP SENSE ZONE

Once it reaches this location, the control knows to expect a hard stop before reaching

the hole bottom.

I

514

ADAPTIVE DEPTH INCREMENT

The amount of distance between the surface of the part and the depth of hole.

M

515

M03/M04

The M--code used to turn the spindle clockwise or counter-clockwise.

S

516

SPINDLE SPEED

The speed of the spindle. Measured in revolutions per minute.

Required entry

Optional entry

d -

This value is written into the cycle. It is .01 inches (.254 mm).