Template 13: boring cycle, dwell/feed out, Chapter 31 – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 846

Using Transfer Line Cycles

Chapter 31

31-44

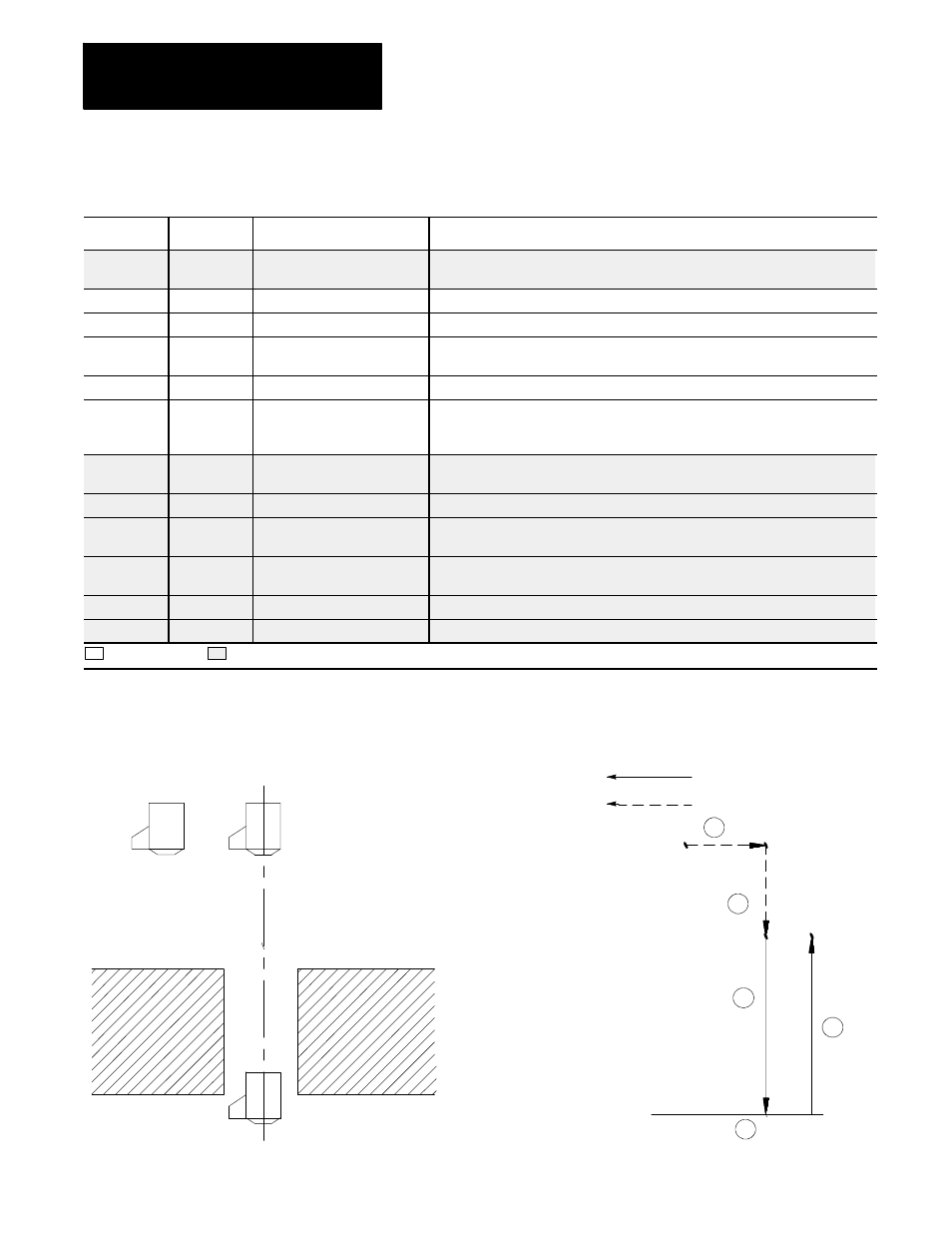

Template 13: Boring Cycle, Dwell/Feed Out

Letter

Paramacro

Label

Description

G

500

G90/91

G-codes G90 or G91 for absolute or incremental modes. At this time only absolute

mode, G90, is available.

X,Y

501, 502

HOLE POSITION X, Y

The location to which the tool moves before it begins a boring operation.

X

503

DEPTH OF HOLE

The location to which the tool bores into the part.

R

504

CLEAR POSITION

The location that the tool retracts to after an operation. It is completely free of the

part. This also known as the R plane.

X,Y

505, 506

RETURN POSITION X, Y

The location where the controls starts and stops a cycle.

F

507

FEEDRATE

The feedrate for drilling/boring operations, and all moves represented by the solid

lines in the QuickView screens. This is also the maximum feedrate for operations

that use adaptive depth.

P

508

AMOUNT OF DWELL

The amount of time the axis pauses before it retracts from the hole; measured in

seconds.

X

509

TOOL CHANGE POSITION

The location the control moves to so that a tool change may be performed.

I

510

HARD STOP SENSE ZONE

Once it reaches this location, the control knows to expect a hard stop before

reaching the hole bottom.

I

511

ADAPTIVE DEPTH

INCREMENT

The amount of distance that the control will increment the tool into the part during an

adaptive depth operation.

M

512

M03/M04

The M--code used to turn the spindle clockwise or counter-clockwise.

S

513

SPINDLE SPEED

The speed of the spindle. Measured in revolutions per minute.

Required entry

Optional entry

Figure 31.16

Boring Cycle, Dwell/Feed Out

Dwell

R

1

2

3

4

5

Cutting feedrate

Maximum cutting feedrate

Depth of Hole

Clear Position

Hole Position

Return

Position