Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 294

Introduction to Programming

Chapter 10

10-20

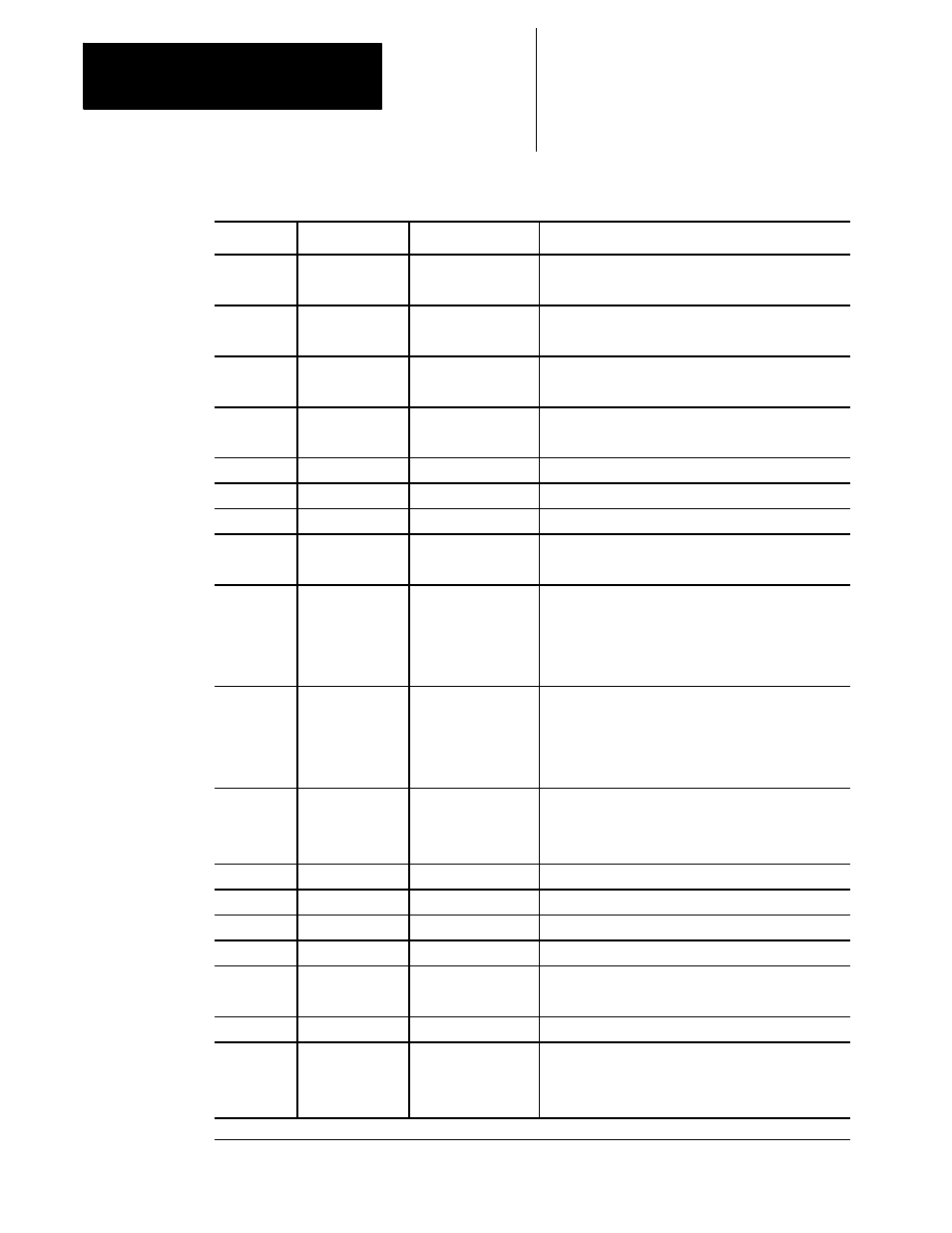

Table 10.B

Word Formats and Descriptions

Address

Valid Range Inch

Valid Range Metric

Function

A

8.6

8.5

Rotary axis about X (AMP assigned)

3.3

3.3

Angle in QuickPath Plus programming

B

8.6

8.5

Rotary axis about Y (AMP assigned)

3.0

3.0

Second miscellaneous function (AMP assigned)

C

8.6

8.5

Rotary axis about Z (AMP assigned)

8.6

8.5

Chamfer length in QuickPath Plus programming

D

3.0

3.0

Tool radius compensation number

8.6

8.5

Fixed cycle parameter.

E

2.6

3.7

Thread lead

F

8.6

8.5

Feedrate function (F--word)

G

2.1

2.1

Preparatory function (G--code)

H

6.0

6.0

Tool length offset number

8.6

8.5

Parameter for probing cycles.

I

8.6

8.5

X arc center in circular interpolation

8.6

8.5

X lead in helical interpolation

8.6

8.5

Parameter in fixed cycles (AMP assigned)

8.6

8.5

Exit move vector in cutter compensation

J

8.6

8.5

Y arc center in circular interpolation

8.6

8.5

Y lead in helical interpolation

8.6

8.5

Parameter in fixed cycles (AMP assigned)

8.6

8.5

Exit move vector in cutter compensation

K

8.6

8.5

Z arc center in circular interpolation

8.6

8.5

Parameter in fixed cycles (AMP assigned)

8.6

8.5

Exit move vector in cutter compensation

L

3.0

3.0

Number of repetitions

M

3.0*

3.0*

Miscellaneous function

N

5.0

5.0

Sequence number

O

5.0

5.0

Program name

P

5.0

5.0

Subprogram name

5.3

5.3

Length of dwell in G04 and fixed cycles

Q

8.6

8.5

Parameter in fixed cycles

R

8.6

8.5

Arc radius

8.6

8.5

Return point in fixed cycles

8.6

8.5

QuickPath Plus radius designation

* Some of the system basic M--codes are 3.1 format however all system installer defined M--codes must remain 3.0. See Table 10.F on page for details.