Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 881

Error and System Messages

Appendix B

B-9

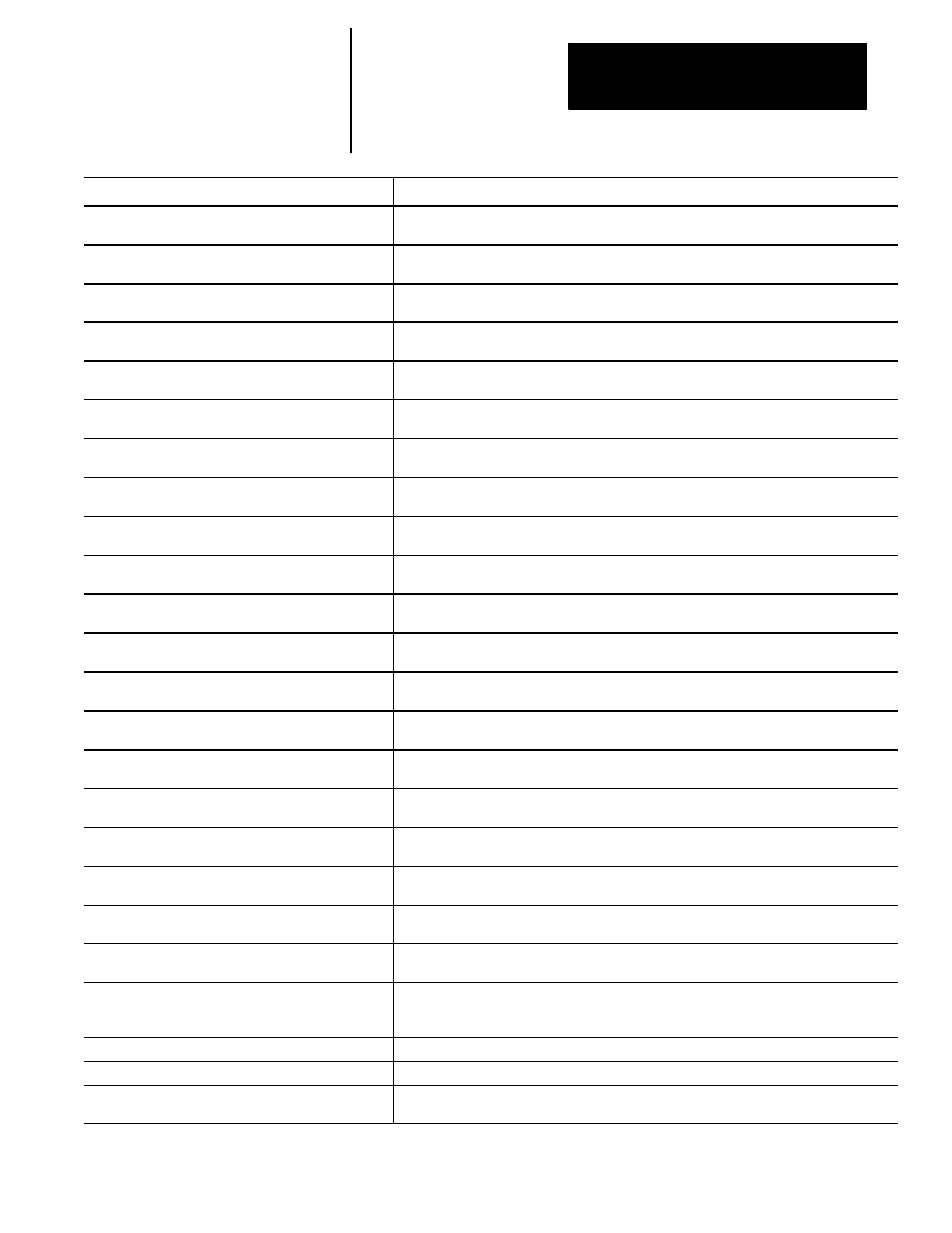

Message

Description

CPU #2 HARDWARE ERROR #4

The 68030 main processor has detected an illegal address. Consult Allen-Bradley customer

support services (9/290 only).

CPU #2 HARDWARE ERROR #6

The 68030 main processor has detected a privilege violation. Consult Allen-Bradley customer

support services (9/290 only).

CPU #2 HARDWARE ERROR #8

CPU #2 has detected an unassigned vector interrupt. Consult Allen-Bradley customer support

services (9/290 only).

CPU #2 HARDWARE ERROR #9

CPU #2 has detected an illegal instruction. Consult Allen-Bradley Customer Support Services

(9/290 only).

CPU #2 LOCAL RAM FAILED

The RAM memory supporting the 68030 I/O ring processor has failed (Z80 I/O ring processor on

9/240 only). Consult Allen-Bradley customer support services.

CPU #2 PROM HAS FAILED

The PROM memory supporting the 68030 (Z80 9/240 only) I/O ring processor has failed its

checksum test. Consult Allen-Bradley customer support services.

CPU #2 RAM HAS FAILED

The RAM memory supporting the 68030 (Z80 9/240 only) I/O ring processor has failed. Consult

Allen-Bradley customer support services.

CPU #2 WATCHDOG ERROR

The 68030 (Z80 9/240 only) I/O ring processor has failed. Consult Allen-Bradley customer

support services.

CREATING BACKUP FILE - PLEASE WAIT

A backup file for the current utility is being created. The message will clear when the backup is

complete.

CREATING TOOL OFFSET FILE - PLEASE WAIT

The tool offset table (or tables) is currently being backed-up. The control is generating an

executable G10 program and entering it into the control’s program directory.

CREATING TOOL MGMT. FILE - PLEASE WAIT

The tool management tables are currently being backed-up. The control is generating an

executable G10 program and entering it into the control’s program directory.

CSS RPM LIMIT AUXILIARY SPINDLE 2

The aux spindle 2 RPM requested by CSS is greater than the maximum CSS RPM limit. This

limit is set by the system installer in AMP or can be reduced by programming a G92 block.

CSS RPM LIMIT AUXILIARY SPINDLE 3

The aux spindle 3 RPM requested by CSS is greater than the maximum CSS RPM limit. This

limit is set by the system installer in AMP or can be reduced by programming a G92 block.

CSS RPM LIMIT FIRST SPINDLE

The spindle 1 RPM requested by CSS is greater than the maximum CSS RPM limit. This limit is

set by the system installer in AMP or can be reduced by programming a G92 block.

CSS RPM LIMIT PRIMARY SPINDLE

The primary spindle RPM requested by CSS is greater than the maximum CSS RPM limit. This

limit is set by the system installer in AMP or can be reduced by programming a G92 block.

CSS RPM LIMIT SECOND SPINDLE

The spindle 2 RPM requested by CSS is greater than the maximum CSS RPM limit. This limit is

set by the system installer in AMP or can be reduced by programming a G92 block.

CSS RPM LIMIT THIRD SPINDLE

The spindle 3 RPM requested by CSS is greater than the maximum CSS RPM limit. This limit is

set by the system installer in AMP or can be reduced by programming a G92 block.

CUR LOOP G/A CLOCK LOST

This error was generated by a servo amplifier error. It can usually be corrected by turning off

power to the amplifier, and then back on.

CURRENT FEEDBACK ERROR

The servo module has detected faulty or missing current feedback from the digital servo motor.

The most likely cause of this error is be a broken or disconnected wire.

CURSORING NOT ALLOWED

While assigning a {CUSTOM TOOL} in {RANDOM TOOL}, you cannot cursor to select another

tool position.

CUTTER COMP./TTRC INTERFERENCE

The cutter radius is too large, reverse motion is required, or some other cutter compensation

interference exists. Either an alternate tool or an alternate tool path must be programmed.

Another option would be to disable cutter compensation error detection.

CYCLE ALREADY ACTIVE

An attempt was made to start a cycle while another cycle was currently executing.

CYLINDER RADIUS IS ZERO

The cylinder radius was not programmed in a virtual C cylindrical interpolation (G16.1) cycle.

CYLINDRICAL AXIS NOT PRESENT

Cylindrical interpolation was programmed without at least one cylindrical interpolation axes

present (rotary, park, or feed axes).