Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 917

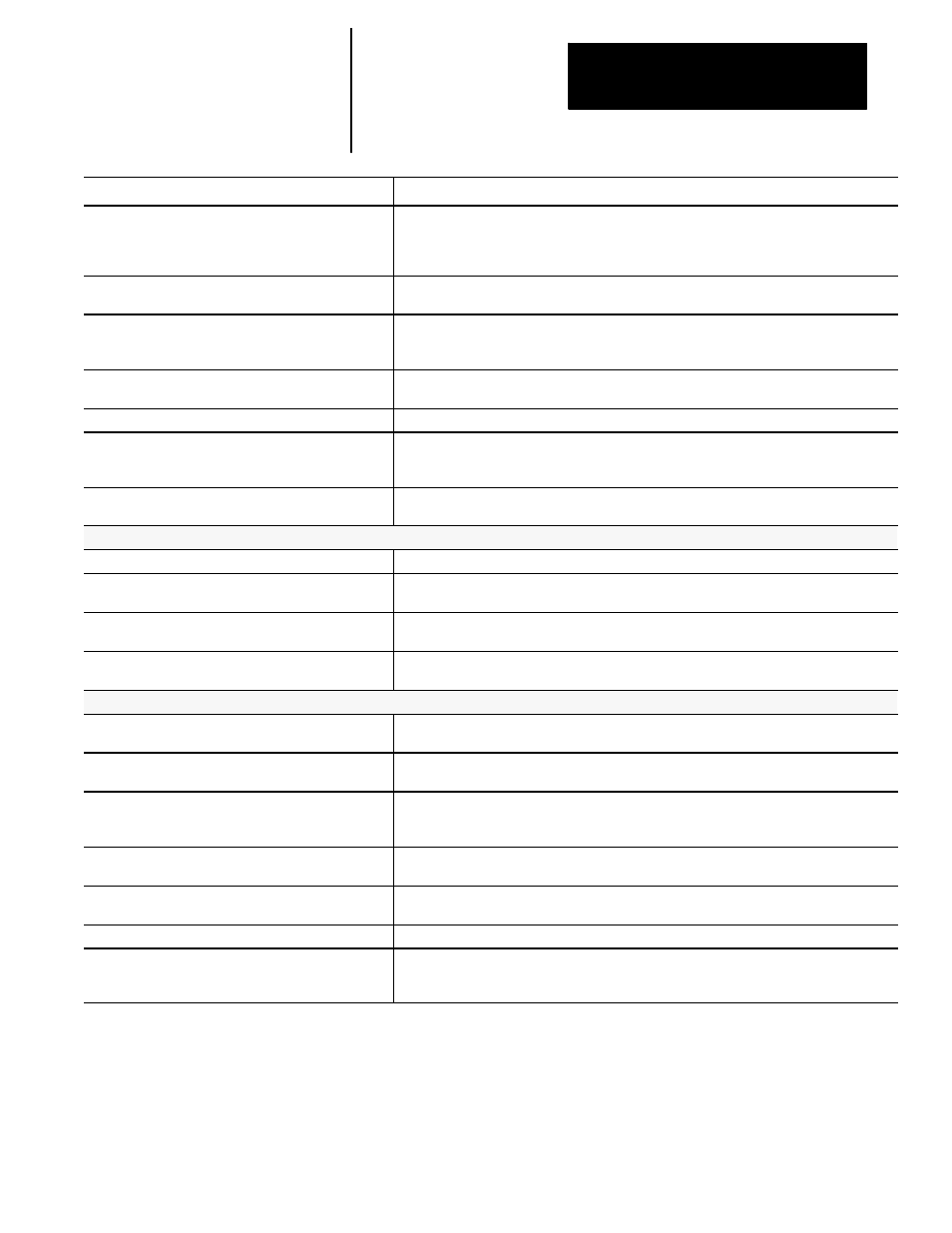

Error and System Messages

Appendix B

B-45

Message

Description

UNABLE TO SYNCH IN CURRENT MODE

The control can not perform the request to synchronize spindles. Possible causes are:

synchronization is already active; virtual/cylindrical programming or a threading operation is

active on the primary or follower spindle when the synchronization request is made; or on a

dual--process system, one of the requesting processes cannot gain control over both spindles.

UNABLE TO WRITE TO FLASH MEMORY

If flash SIMMs appear to be installed correctly, remove and reseat SIMMs. If problem persists,

contact Allen--Bradley support service.

UNDEFINED INTERRUPT MACRO/SUBPROG

An interrupt program request was received by the control, but it cannot find the paramacro or

sub-program with the corresponding program name in the program directory. The program

name is defined in the enable block (M96) with a P-word.

UNEXPECTED DEPTH PROBE TRIP

G26 adaptive depth probe has fired unexpectedly. Either it has fired in a non-G26 block or it has

fired before the programmed G26 contact range.

UNSPECIFIED NETWORK ERROR

An error is being sent from another device that the module cannot interpret.

UNUSABLE WORDS IN ZONE BLOCK

An axis word or other data was programmed in a programmable zone block (G22, G22.1 G23,

G23.1). These G-codes must be programmed in blocks containing no other data except a block

delete /, N word, or comments.

UNRECOVERABLE ERROR

Can occur when updating flash SIMMs with new 9/Series firmware. Retry the update utility. If

problem persists, call Allen-Bradley Support Services.

V

VEL LOOP INVALID WITH DAC OUT

An attempt was made to select the position/velocity servo loop type on a 9/440HR system.

VIRTUAL AXIS NOT ALLOWED

The virtual axis can only be programmed when the control is in a virtual axis mode. You must

place the control in G16.3 mode to program a virtual axis.

VIRTUAL C NEEDS SPINDLE WITH FDBK

When the spindle is the virtual C axis in a virtual C application, it must be configured to provide

feedback to the servo module.

VIRTUAL/REAL AXIS NAME CONFLICT

The axis configured in AMP as the Virtual C axis was previously configured as a linear machine

axis.

W

WARNING - G10 OFFSETS ALTERED

This message warns that the offsets were changed by a G10 block during execution from a

mid-program start.

WARNING - PROGRAM STARTING AT BEGINNING

An active program was edited and then the editor exited. This causes the active program to

restart at the beginning of the program.

WARNING - VERIFY MODAL CODES

The MID START PROGRAM feature that activates modal codes for mid-program execution is

requesting that these generated modal codes be checked before program execution is started.

These modal codes can be checked on the G- and M-code status screens.

WARNING -- WATCHDOG JUMPER IS INSTALLED

This error indicates that the watchdog has been bypassed on the 9/Series hardware and your

system will not report watchdog errors. Call Allen-Bradley field service.

WHEEL AXIS MOTION INVALID IN G16.3/G16.4

While in the angled wheel grinding mode you have attempted to program the wheel axis directly.

Only the virtual axis and the axial axis can be programmed in angled wheel mode.

WILDCARD MUST BE AT START/END OF SYMBOL

You have used incorrect search string syntax in the PAL search monitor utility.

WORK CO-ORD CHANGES NOT ALLOWED

You have attempted to make a change to the work coordinate system at an invalid time.

Changes to the work coordinate system can not be performed when some features are active.

Disable the offending feature before attempting to change coordinate systems.