Programming feedrates, 0 chapter overview 18.1 feedrates – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 449

Chapter

18

18-1

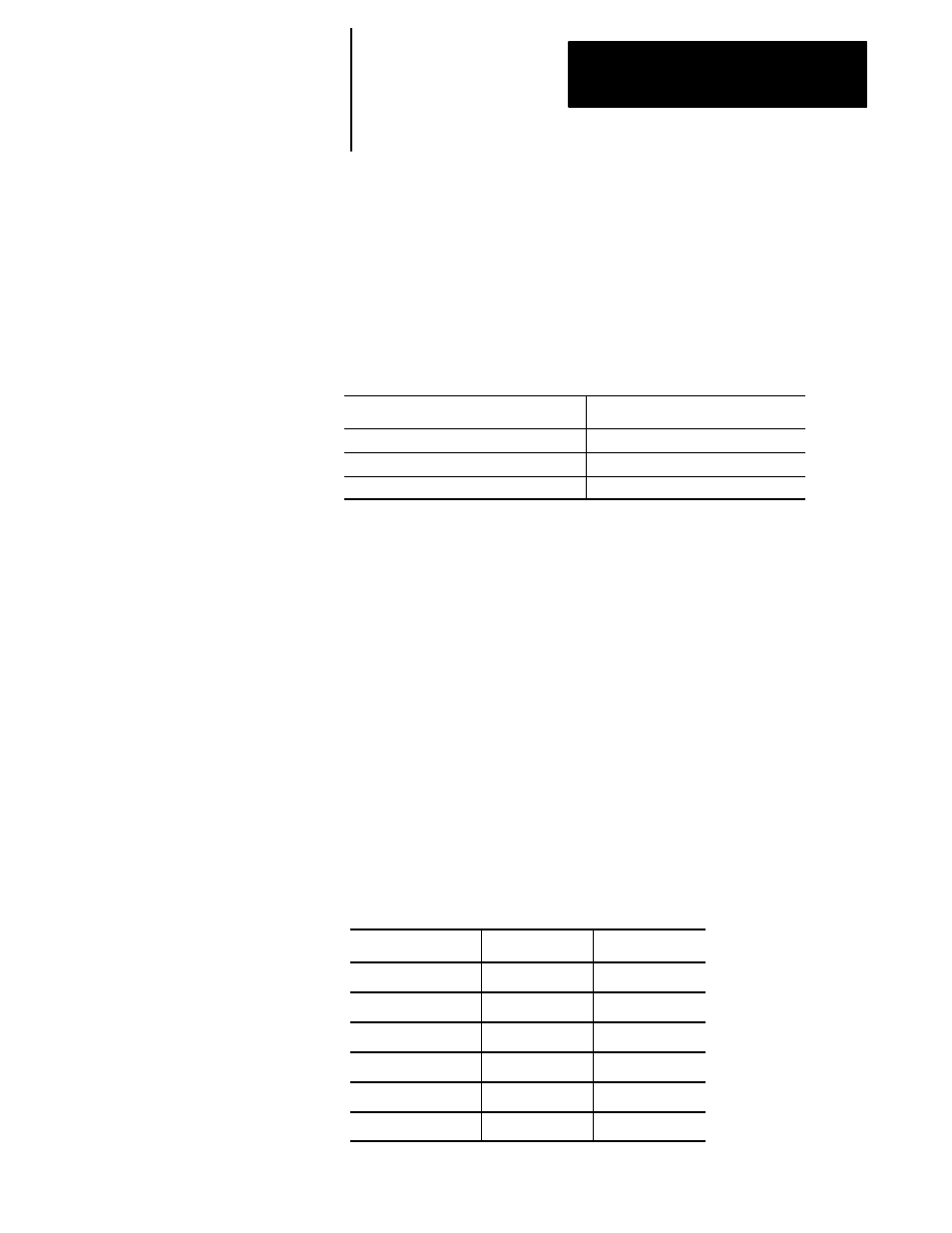

Programming Feedrates

This chapter describes how to program feedrates and

acceleration/deceleration. Use this table to find the information in this

chapter:

Information about:

On page:

Feedrates

18-1

Special AMP Assigned Feedrates

18-12

Automatic Acceleration/Deceleration

18-14

Feedrates are programmed by an F--word followed by a numeric value.

Feedrates can be entered in a part program block or through MDI. They

become effective in the block in which they are programmed. If the block

requires rapid traverse motion (G00), the programmed feedrate will be

ignored for that block, but will be stored in control memory as the active

feedrate.

Feedrates are modal, meaning that they remain active in control memory

unless replaced with a different feedrate programmed with an F--word.

The feedrate programmed with the F--word applies to linear interpolation

(G01), and circular interpolation (G02/G03) modes. For simplification this

manual refers to the cutting tool moving relative to the part, even though

most mills move the part across a stationary cutter.

Feedrate modes are either G93 (inverse time feed), G94 (feed per minute),

or G95 (feed per spindle revolution). The following table shows the

possible feedrate units depending on axis type.

Active G Code

Linear Axis Feed

Rotary Axis Feed

G20/G21 and G93

moves/min.

moves/min.

G02/G03 and G93

radians/min.

moves/min.

G21 and G94

millimeters/min.

degrees/min.

G20 and G94

inches/min.

degrees/min.

G21 and G95

millimeters/rev.

degrees/rev

G20 and G95

inches/rev.

degrees/rev.

18.0

Chapter Overview

18.1

Feedrates